As the raw material of aluminum plate, aluminum foil and other products, aluminum has been widely concerned. The quality of aluminum directly determines the quality of products such as aluminum sheets. The corrosion resistance of aluminum is very important. In this paper, the causes of aluminum corrosion and the intergranular corrosion susceptibility of 6000 series aluminum alloys were evaluated.

The corrosion of aluminum and aluminum alloys mainly includes pitting corrosion, intergranular corrosion, stress corrosion cracking and laminar corrosion. 6000 series alloys have the largest output among deformed aluminum alloys. Although its corrosion resistance is not as good as that of 1000 series, 3000 series, and 5000 series aluminum alloys, it is much higher than 2000 series and 7000 series aluminum alloys. The intergranular tendency of 6000 series alloys is also relatively large.

Classification of Aluminum Corrosion

From the perspective of corrosion morphology, aluminum corrosion can be divided into general corrosion and local corrosion. The former is also called uniform corrosion, also known as overall corrosion, which means that the surface of the material in contact with the environment is uniformly corroded and lost.

The corrosion of aluminum in alkaline solution is typical uniform corrosion, such as alkaline washing, the corrosion result is that the aluminum surface is thinned at approximately the same rate and the quality is reduced. It should be pointed out, however, that uniform corrosion does not exist, and the reduction in thickness varies from place to place.

Localized corrosion means that the occurrence of corrosion is limited to a specific area or part of the structure, and can be divided into the following categories:

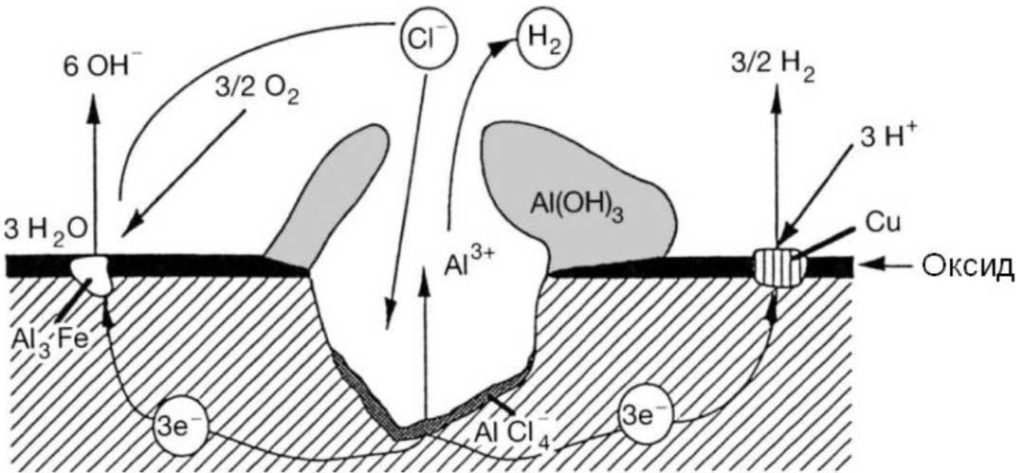

Pitting Corrosion of Aluminum

The pitting corrosion of aluminum occurs in very localized areas or parts of the metal surface, causing cavities or pits to expand and even cause perforations.

If the diameter of the pit opening is smaller than the depth of the pit, it is called pitting corrosion; if the diameter of the pit opening is greater than the depth of the pit, it can be called pitting corrosion. In fact, there is no strict boundary between pitting and pitting.

Typical pitting corrosion of aluminum in chloride-containing aqueous solutions. Among the corrosion of aluminum, pitting corrosion is the most common, which is caused by the potential of a certain area of aluminum being different from that of the substrate, or by the presence of impurities whose potential is different from that of the aluminum substrate.

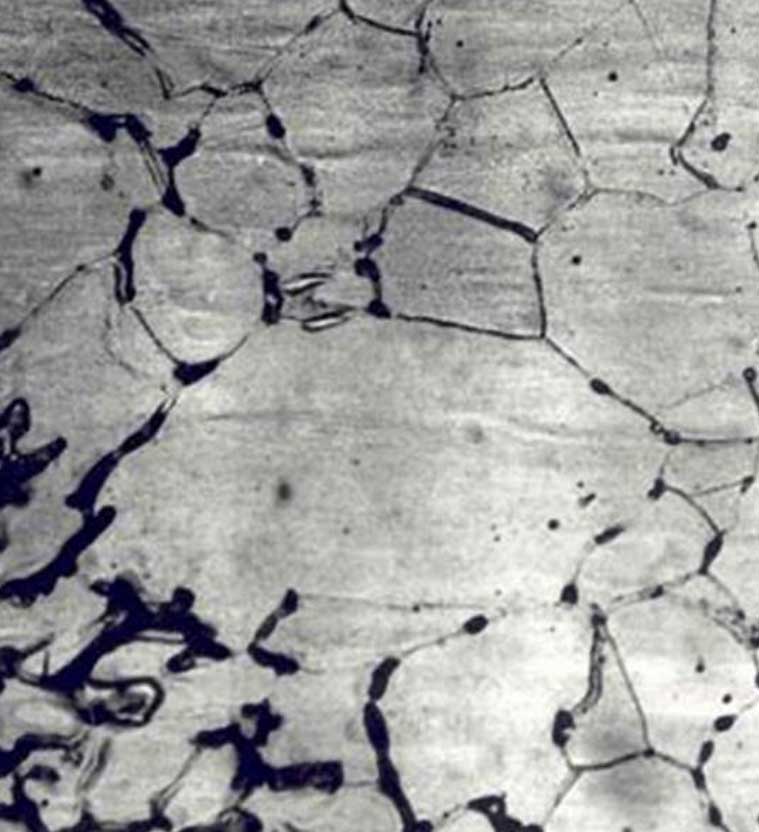

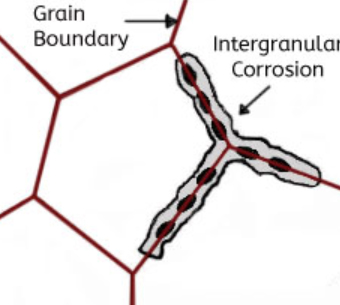

Intergranular Corrosion of Aluminum

This kind of corrosion is selective corrosion that occurs at the grain boundaries of metals or alloys when the grains or crystals themselves are not significantly eroded, which will drastically reduce the mechanical properties of materials, resulting in structural damage or accidents.

The reason for intergranular corrosion is that the grain boundary is very active under certain conditions, such as impurities in the grain boundary, or an increase or decrease of an alloying element in the grain boundary, that is to say, there must be a thin layer on the grain boundary of the rest of the aluminum.

A portion of the electronegative region is preferentially corroded. This corrosion occurs with high-purity aluminum in hydrochloric acid and high-temperature water. Al-Cu, Al-Mg-Si, Al-Mg, and Al-Zn-Mg alloys are all sensitive to intergranular corrosion.

Galvanic Corrosion of Aluminum Materials

Galvanic corrosion is also a characteristic corrosion form of aluminum. Galvanic corrosion occurs when a less reactive metal and a more reactive metal such as aluminum (anode) come into contact in the same environment or when conductors are connected, forming a galvanic couple and causing the flow of current.

Galvanic corrosion is also known as bimetallic corrosion or contact corrosion. The natural potential of aluminum is very negative. When aluminum is in contact with other metals, aluminum is always anodic, and corrosion is accelerated. Almost all aluminum and aluminum alloys cannot avoid galvanic corrosion. The greater the potential difference between the two metals in contact, the more serious the galvanic corrosion. It should be noted that in galvanic corrosion, the area factor is extremely important, and a large cathode and a small anode are the most unfavorable combination.

Stress Corrosion Cracking of Aluminum Plate

Stress corrosion cracking is corrosion cracking caused by the coexistence of tensile stress and specific corrosive media. Stress can be external or internal residual stress in the metal, the latter may be caused by deformation during processing, severe temperature changes during quenching, or volume changes caused by changes in internal structure.

Stresses resulting from riveting, bolting, press fitting, and shrink fitting are also residual stresses. When the tensile stress on the metal surface reaches the yield strength Rp0.2, stress corrosion cracking occurs.

The 2000 series and 7000 series aluminum alloy thick plates will generate residual stress during quenching, which should be pre-stretched before aging treatment to avoid deformation or even into the parts when machining aircraft parts.

Intergranular Corrosion of 6000 Series Aluminum Alloys

Among the wrought aluminum alloys used today, the most widely used are 6000 series alloys that can be strengthened by heat treatment, which are a class of Al-Mg-Si and Al-Mg-Si-Cu alloys. In 2018, there were 706 common and uncommon alloys registered with The Aluminum Association, Inc., of which 6000 series alloys were the most, with 126, accounting for 18%.

6000 series aluminum has been widely used in the construction industry, structural field, and transportation equipment because of its good formability, moderate strength, and excellent corrosion resistance. However, if the alloy composition ratio is not appropriate, the heat treatment parameters are not properly selected, or the processing and forming are not appropriate, intergranular corrosion will occur in a chlorine-containing environment.

In most cases, intergranular corrosion occurs in alloys containing a small amount of copper and high Si/Mg. Usually, the copper content of most copper-containing alloys is less than 0.4%, and only 4 alloys such as 6013, 6113, 6056, and 6156 have copper content is as high as 1.1%, and copper is added to the Al-Mg-Si alloy to improve the mechanical properties of the alloy.

The study found that all alloys with intergranular corrosion susceptibility were often found to have copper-rich segregation layers and cathodic Q-phase precipitates when observed with high-resolution scanning transmission electron microscopy. The Q phase is a quaternary intermetallic phase with a molecular formula of Cu2Mg8Si5Al4, which precipitates along the grain boundary, causing anodic dissolution of the adjacent solid solution to form a precipitate-free zone.

Intergranular corrosion susceptibility inspection of aluminum plates and other aluminum materials

There are two commonly used inspection methods for the intergranular corrosion susceptibility of aluminum alloys: field (field) test and accelerated immersion test.

In accelerated testing, to accelerate corrosion, potassium chloride solution containing hydrochloric acid (ISO 11846 Method B) or potassium chloride solution with hydrogen peroxide (ASTM G110) are often used. After the test, the metallographic observation of the cross-section of the sample or the measurement of the loss of its mechanical properties.

The ISO 11846 accelerated test results are in high agreement with the marine atmosphere field test results, but the intergranular corrosion-susceptible aluminum material exhibits severe corrosion on almost all grain boundaries near the surface of the sample during the accelerated test (uniform intergranular corrosion). ), whereas the surface of the field test specimens corroded only in limited areas (localized corrosion). Nonetheless, accelerated testing remains the standard method for accurately determining whether a material has grain boundary corrosion.

The automotive industry often judges whether 6000 series aluminum alloys have intergranular corrosion according to the ISO 11846 Method B standard. When testing according to this standard, first fully immerse a small sample (surface area < 20cm2) in an acidic sodium chloride solution (pH=1) at room temperature for 24 hours, and then perform a metallographic examination to determine the type of corrosion (pitting or intergranular). Corrosion), in addition to determining the percentage of corrosion damaged surface and the maximum corrosion depth.

Summarize

The 6000 series alloy is not only a kind of deformed aluminum alloy with wide application, large output and many varieties (brands), but also one of the deformed alloys with high sensitivity to intergranular corrosion.

However, as long as the process specifications are strictly followed in the production, especially the heat treatment process, the structure design is reasonable, and the manufacturing is excellent, this kind of corrosion can be completely avoided.

The intergranular corrosion susceptibility of the 6000 series aluminum alloy structure and parts is also closely related to its working environment. When designing the structure, attention should be paid to whether corrosion will occur during the processing of the aluminum material.