Aluminum tubes are a versatile and widely used material in a variety of applications. They are strong, lightweight, and corrosion-resistant, making them ideal for use in a wide range of environments. There are two main types of aluminum tubes: extruded aluminum tubes and seamless aluminum tubes. In this article, we will compare the properties and applications of extruded and seamless aluminum tubes. We will also discuss the best type of aluminum tube for a particular application.

What are Extruded Aluminum Tubes?

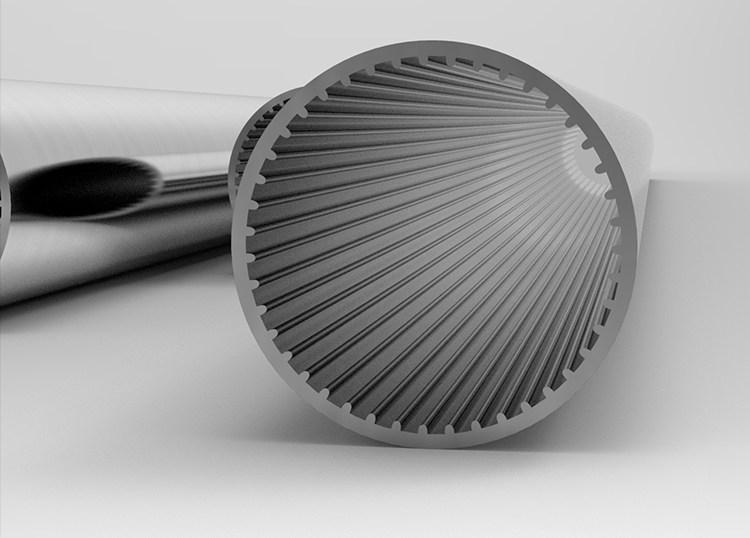

Extruded aluminum tubes are made by forcing a billet of aluminum through a die. The die is a hollow profile that shapes the aluminum into a specific shape. The extrusion process can produce a wide variety of tube shapes, including round, square, rectangular, and triangular tubes.

Extruded aluminum tubes are typically stronger than seamless aluminum tubes. This is because the extrusion process aligns the grains of the aluminum in the direction of the tube’s axis. This alignment of the grains makes the tube more resistant to bending and twisting.

Extruded aluminum tubes are also typically less expensive than seamless aluminum tubes. This is because the extrusion process is a more efficient manufacturing process.

What are Seamless Aluminum Tubes?

Seamless aluminum tubes are made by piercing a hole in a billet of aluminum and then drawing the hole out to form a tube. The drawing process is a continuous process that stretches the aluminum until it forms a tube with a uniform wall thickness.

Seamless aluminum tubes are typically more uniform in wall thickness and have a smoother surface finish than extruded aluminum tubes. This is because the drawing process does not create any welds or seams in the tube.

Seamless aluminum tubes are also typically more difficult to manufacture than extruded aluminum tubes. This is because the drawing process requires a more precise control of the temperature and the rate of deformation of the aluminum.

Properties of Extruded and Seamless Aluminum Tubes

The following table summarizes the key properties of extruded and seamless aluminum tubes:

| Property | Extruded Aluminum Tube | Seamless Aluminum Tube |

| Strength | Stronger | Weaker |

| Uniformity of wall thickness | Less uniform | More uniform |

| Surface finish | Rougher | Smoother |

| Cost | Less expensive | More expensive |

Applications of Extruded and Seamless Aluminum Tubes

Applications of Extruded Aluminum Tubes

- Structural applications: Extruded aluminum tubes are often used in structural applications where strength is important. For example, they are used in the construction of buildings, bridges, and other structures. They are also used in the manufacture of furniture, appliances, and other consumer products.

- Transportation applications: Extruded aluminum tubes are also used in transportation applications, such as in the manufacture of cars, trucks, boats, and airplanes. They are used in these applications because they are lightweight and strong, making them ideal for use in vehicles.

- Industrial applications: Extruded aluminum tubes are also used in industrial applications, such as in the manufacture of machinery, equipment, and tools. They are used in these applications because they are durable and corrosion-resistant, making them ideal for use in harsh environments.

Applications of Seamless Aluminum Tubes

- Food and beverage industry: Seamless aluminum tubes are often used in the food and beverage industry because they are non-reactive and have a smooth surface finish. This makes them ideal for use in applications where food or beverages are being transported or stored.

- Medical industry: Seamless aluminum tubes are also used in the medical industry, such as in the manufacture of IV tubes and other medical devices. They are used in these applications because they are sterile and have a smooth surface finish.

- Aerospace industry: Seamless aluminum tubes are also used in the aerospace industry, such as in the manufacture of aircraft wings and fuselages. They are used in these applications because they are lightweight and strong, making them ideal for use in aircraft.

Conclusion

The best type of aluminum tube for a particular application will depend on the specific requirements of that application. If strength is the most important factor, then an extruded aluminum tube may be the best choice. If a smooth surface finish is more important, then a seamless aluminum tube may be the best choice.