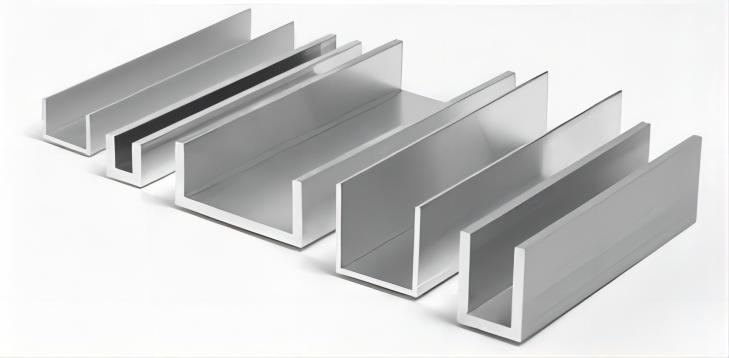

Aluminum channels are a ubiquitous yet versatile component found in countless applications across various industries. These long, extruded shapes offer a unique combination of strength, lightweight design, and corrosion resistance, making them a popular choice for construction, manufacturing, and even DIY projects. This article delves into the five most common types of aluminum channels – U channel, C channel, H channel, Z channel, and hat channel – exploring their distinct profiles, common uses, and factors to consider when selecting the right one for your needs.

Understanding Aluminum Channels

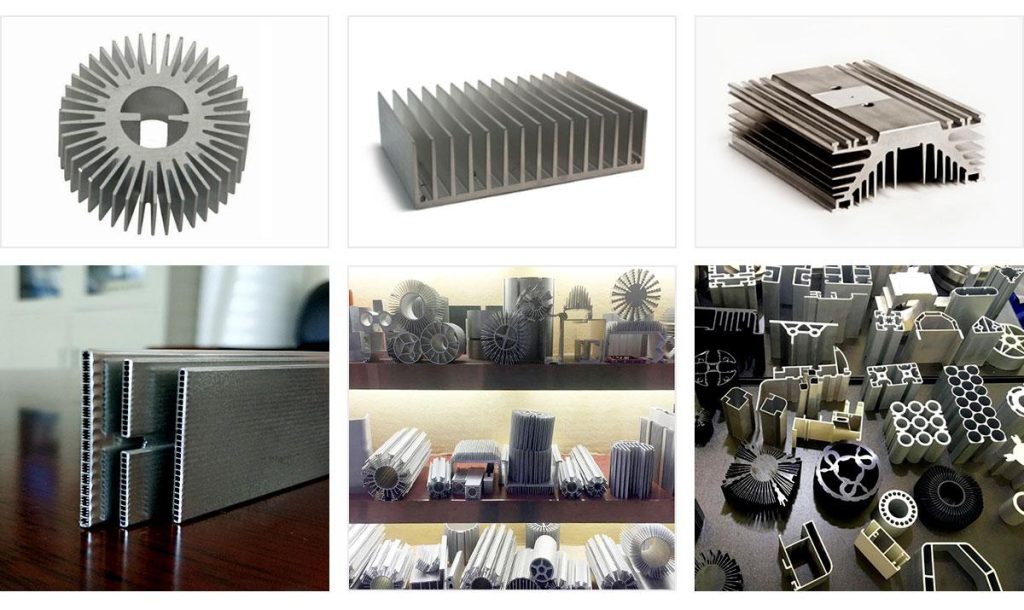

Aluminum channels are formed through a process called extrusion, where molten aluminum is forced through a die to create a specific cross-sectional shape. This process allows for the creation of intricate profiles with consistent dimensions, ensuring structural integrity and ease of use. The primary benefit of aluminum channels lies in their exceptional strength-to-weight ratio. Compared to steel, aluminum offers nearly one-third the weight while maintaining comparable durability. Additionally, aluminum naturally resists corrosion, making it suitable for environments with moisture or exposure to the elements.

Types of Aluminum Channels and Their Applications

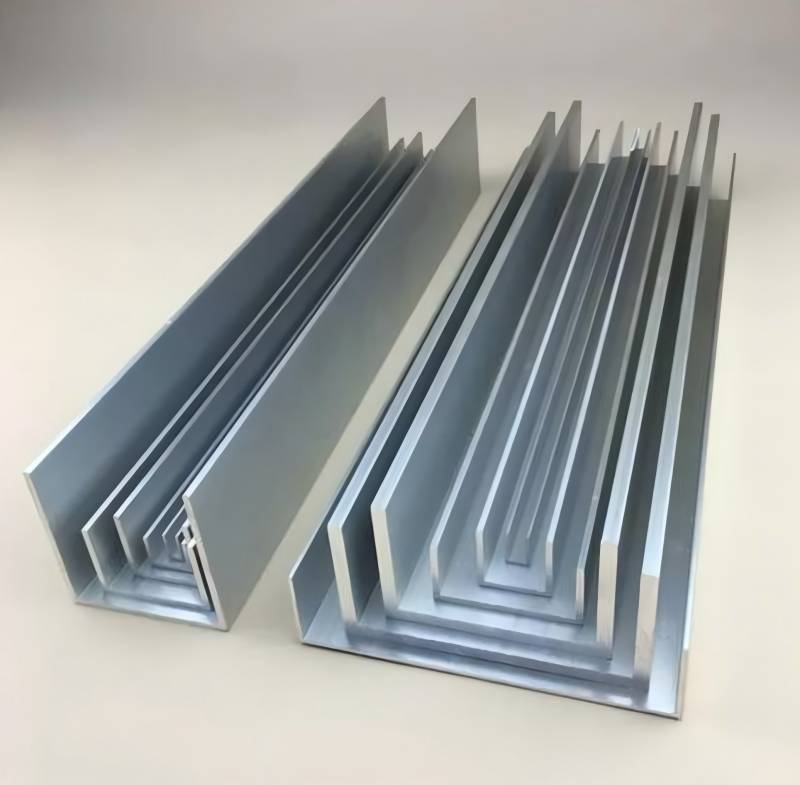

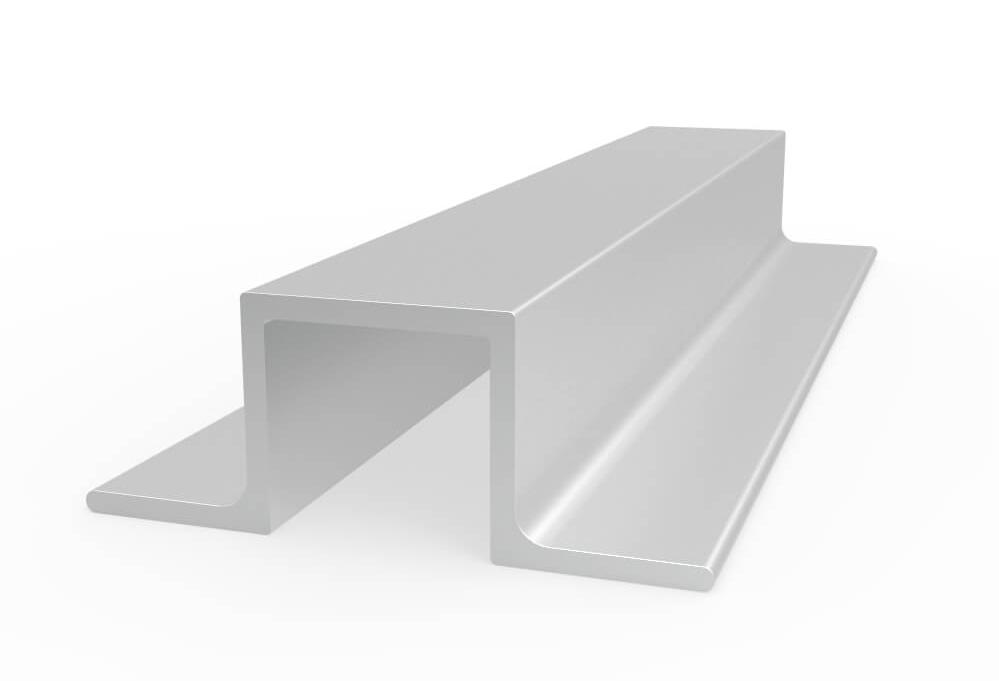

1. Aluminum U Channel

The aluminum U channel, as the name suggests, boasts a profile resembling the letter “U.” It features a flat base with two upright flanges running parallel to each other.

Common Applications:

- Trims and Edging: U channels excel in applications where a clean, finished edge is desired. They are commonly used for finishing edges on furniture, countertops, shelving units, and even flooring.

- Cable Management: Due to their enclosed design, U channels provide a convenient way to organize and conceal electrical wires and cables. They are frequently used in data centers, server racks, and under-desk cable management systems.

- Signage and Displays: U channels can be employed to frame signs and displays, offering a sleek and professional aesthetic.

2. Aluminum C Channel

The aluminum C channel features a profile resembling the letter “C.” It has a flat base with a single, upright flange extending perpendicularly from one side.

Common Applications:

- Framing: C channels are a popular choice for constructing lightweight frames due to their ability to provide significant structural support. They are used in building partitions, creating temporary structures, and even framing for furniture pieces.

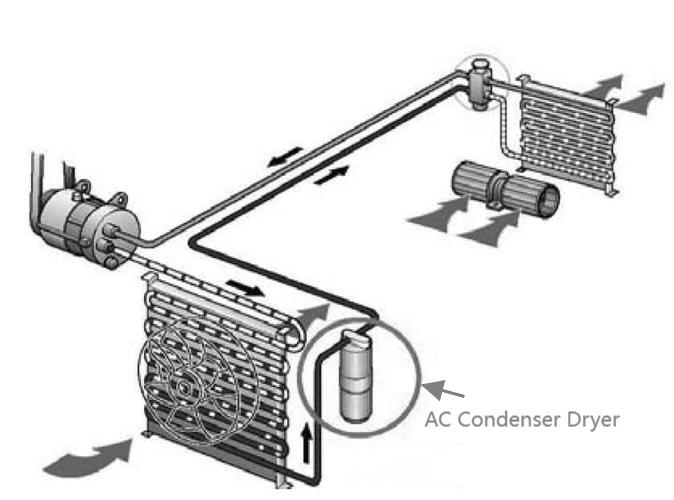

- Support Structures: C channels’ inherent strength makes them ideal for creating support beams and reinforcements. They can be used to support shelving units, hanging fixtures, and even ductwork in HVAC systems.

- Tracks: The open face of a C channel allows for smooth movement, making it suitable for applications like drawer slides, sliding door tracks, and conveyor systems.

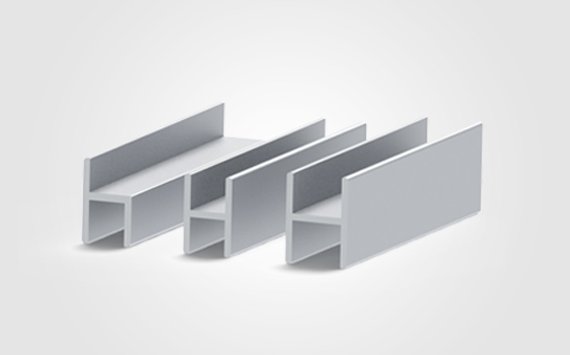

3. Aluminum H Channel

The aluminum H channel boasts a profile resembling the letter “H.” It features a flat web with two flanges extending outwards on opposite sides, creating an H-shaped cross-section.

Common Applications:

- Reinforcement: H channels are ideal for reinforcing beams, columns, and other structural components due to their ability to distribute weight evenly across their flanges.

- Joining Panels: H channels can be used to securely connect two flat panels, creating a rigid and stable joint. This application is common in the construction of walls, partitions, and even furniture.

- Signage and Displays: Similar to U channels, H channels can be used to frame signs and displays, offering increased rigidity due to the double flange design.

4. Aluminum Z Channel

The aluminum Z channel features a profile resembling the letter “Z.” It has a flat base with two flanges extending upwards at an angle, forming a Z-shaped cross-section.

Common Applications:

- Flashing: Aluminum Z channels are widely used in roofing applications as flashing material. Their angled flanges effectively channel water away from building walls and prevent leaks.

- Countertops: Aluminum Z channels can be used as an edging material for countertops, providing a secure and aesthetically pleasing finish.

- Cladding and Trims: Similar to U channels, Z channels can be used for cladding and trimming applications due to their ability to create a clean, finished edge.

5. Aluminum Hat Channel

The aluminum hat channel boasts a profile similar to an Aluminum U channel but with one key difference. It features a flat base with two upright flanges, with one flange significantly wider than the other, resembling a hat brim.

Common Applications:

- Shelving: Hat channels are a popular choice for constructing sturdy shelves due to their wide flange, which provides excellent support for weight distribution.

- Corner Protection: Hat channels can be used to protect corners from damage and wear. The wider flange acts as a barrier, absorbing impacts and preventing dents or chipping.

- Decorative Trim: Hat channels can be used as decorative trim elements due to their distinctive profile. The wider flange can be adorned with finishes or accents, adding a touch of visual interest to various applications.

Choosing the Right Aluminum Channels

Selecting the appropriate aluminum channel for your project requires considering several factors:

- Size: Aluminum channels come in a wide range of sizes, including width, height, and thickness. The ideal size will depend on the specific application. For instance, a thin U channel might suffice for cable management, while a thicker C channel might be necessary for building a sturdy frame.

- Thickness: The thickness of the channel directly affects its weight capacity and structural integrity. Thicker channels naturally offer greater load-bearing capabilities but come at the expense of increased weight.

- Temper: The temper of aluminum refers to its strength and hardness, achieved through various heat treatment processes. Common temper designations for aluminum channels include T5 (high strength) and T6 (extra high strength). Choosing the right temper depends on the intended use. High-stress applications might necessitate a T6 temper, while a T5 temper might be sufficient for less demanding projects.

- Finish: Aluminum channels are available in various finishes, including mill finish (natural aluminum), anodized (corrosion-resistant oxide coating), and painted finishes. The choice of finish depends on the desired aesthetics, environmental conditions, and potential exposure to elements.

Additional Considerations

- Length: Aluminum channels are generally sold in standard lengths, ranging from a few feet to over 10 feet. If your project requires a specific length, you may need to cut the channel to size. Ensure you have the appropriate tools and cutting techniques to achieve clean, straight cuts.

- Accessories: Depending on the application, you might require additional components to use your aluminum channels effectively. For example, brackets, fasteners, and connectors might be necessary for building frames or attaching channels to other materials.

Conclusion

Aluminum channels offer a versatile and practical solution for a broad spectrum of applications. Their unique combination of strength, weight efficiency, and corrosion resistance makes them a valuable asset in construction, manufacturing, and even DIY projects. Understanding the different types of aluminum channels – U channel, C channel, H channel, Z channel, and hat channel – and considering factors like size, thickness, temper, and finish empowers you to select the ideal channel for your specific needs. From framing and support structures to edging, cladding, and decorative elements, aluminum channels offer a multitude of possibilities to bring your projects to life.