In the realm of construction piping, one material has risen to prominence for its exceptional qualities: seamless aluminum tubes. These tubes, with their impeccable blend of strength, durability, and corrosion resistance, have become an invaluable asset in a variety of applications within the construction industry. In this article, we will delve into the world of seamless aluminum tubing, exploring its myriad benefits and common applications in construction piping.

What is Seamless Aluminum Tubing?

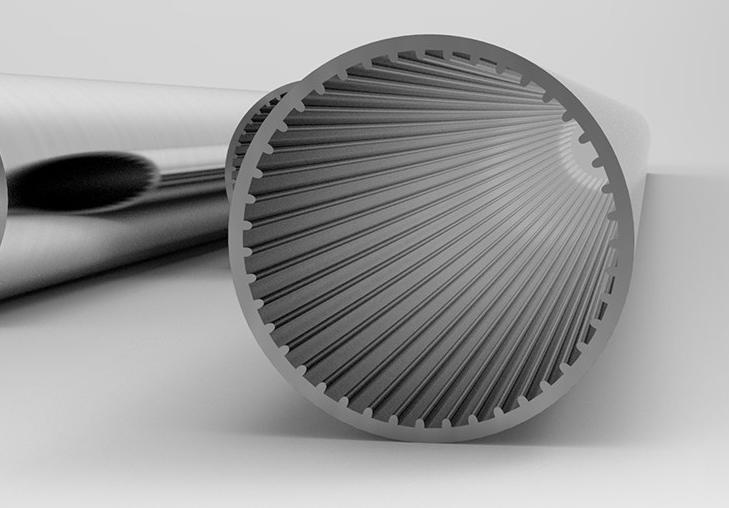

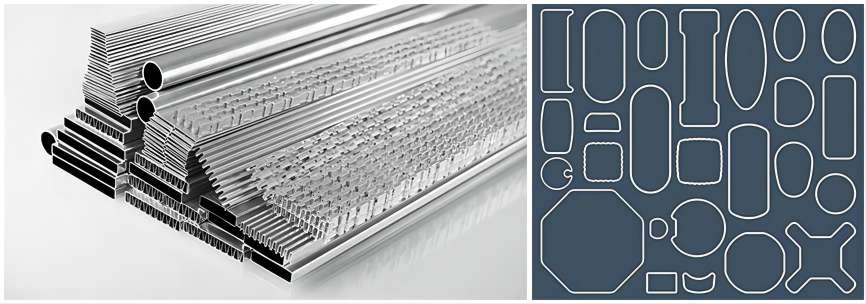

Seamless aluminum tubing, as the name suggests, is manufactured without any welds or seams in its structure. This seamless quality sets it apart from other types of tubing, such as welded tubes, where the weld joints can become weak points. The seamless construction is achieved through a process known as extrusion, wherein a solid billet of aluminum is heated and pushed through a die, forming a continuous tube without any seams. This method results in a product that is not only strong but also consistent in quality.

Benefits of Using Seamless Aluminum Tubing in Construction Piping

The utilization of seamless aluminum tubing in construction piping is growing in popularity due to several key advantages it offers:

- Lightweight: Seamless aluminum tubes are notably lighter than their steel counterparts. This weight advantage simplifies handling, transportation, and installation, making them an attractive option for builders.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which shields it from corrosion. This makes seamless aluminum tubing an ideal choice for applications where exposure to moisture or harsh chemicals is a concern.

- Durability: The absence of seams in seamless aluminum tubing eliminates the potential weak points and vulnerabilities found in welded tubes. This results in a more robust product that can withstand the rigors of construction and industrial use.

- High-Pressure Resistance: Seamless aluminum tubes are capable of withstanding high-pressure environments, making them suitable for applications that involve the transport of fluids or gases under significant force.

Common Applications of Seamless Aluminum Tubing in Construction Piping

Let’s explore the various applications where seamless aluminum tubing shines in the construction piping industry:

1. Water Supply Systems

Seamless aluminum tubes are a trusted choice for water supply lines in both residential and commercial buildings. Their corrosion resistance and durability ensure clean, uncontaminated water delivery to end-users. Additionally, the lightweight nature of these tubes simplifies installation, reducing labor and material costs.

2. Sewage Systems

In sewage systems, where exposure to corrosive and abrasive substances is a daily challenge, seamless aluminum tubing proves to be a resilient choice. It can withstand the harsh environment of sewage lines, providing long-lasting service and reducing maintenance requirements.

3. Underground Pipelines

Seamless aluminum tubing plays a vital role in underground pipelines that transport water, gas, and other fluids. The ability to resist corrosion and damage from surrounding soil ensures the reliability of these pipelines. They also offer significant cost savings, as they are less prone to deterioration, minimizing the need for replacements and repairs.

4. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems benefit from the lightweight and corrosion-resistant properties of seamless aluminum tubes. They are commonly used in refrigerant lines, condensate drain lines, and other applications within HVAC systems, ensuring efficient and long-lasting operation.

5. Fire Protection Systems

In fire protection systems, the importance of reliability cannot be overstated. Seamless aluminum tubing is a popular choice for sprinkler lines, standpipes, and other applications due to its lightweight nature and corrosion resistance. It ensures that fire protection systems are always ready to respond when needed.

6. Structural Support

Seamless aluminum tubing is not limited to fluid transport applications. It also finds use as a component of structural support in construction projects. The combination of strength and lightness makes it an ideal choice for structures where weight-bearing elements need to be both robust and easy to handle.

Conclusion

Seamless aluminum tubing has carved a niche for itself in the construction piping industry due to its exceptional qualities. Its resistance to corrosion, lightweight nature, and ability to withstand high pressures make it a versatile material for a range of applications. As the construction industry continues to evolve, seamless aluminum tubing will likely remain a crucial player in enhancing the efficiency, durability, and safety of piping systems in various construction projects. Its future is indeed seamless, bright, and promising.