From sealing HVAC systems to providing electrical conductivity, aluminum foil tape is an essential tool for many professionals. Made from aluminum foil coated with an adhesive, this tape is used in various industries due to its excellent properties. This article will explore the different types of aluminum foil tape, its numerous uses, the benefits it offers, and recommened you a trusted aluminum foil tape supplier.

Types and Uses of Aluminum Foil Tape

Aluminum foil tape is a versatile material prized for its durability, conductivity, and resistance to moisture and chemicals. Its applications span numerous industries, from construction to electronics. To fully understand the potential of this product, it’s essential to grasp its different classifications.

Classification By Adhesive Type

The adhesive type determines the tape’s performance in various environments and applications.

- Acrylic Adhesive: This type offers superior adhesion, excellent temperature resistance, and long-term stability, making it ideal for outdoor applications where durability and longevity are paramount.

- Rubber Adhesive: Known for its strong initial adhesion and good performance at lower temperatures, it is suitable for indoor use where immediate stickiness is required.

- Silicone Adhesive: With its ability to withstand high temperatures, silicone adhesive is perfect for applications in high-temperature environments, such as heat shields or oven repairs.

Classification By Backing Material

Aluminum foil tape can be classified by the type of backing material used, which influences its performance, durability, and suitability for different applications. Here are the main classifications based on backing material:

1. Pure Aluminum Foil

Soft Aluminum Foil:

- Characteristics: This type of foil is highly flexible and can easily conform to irregular surfaces, making it versatile for a wide range of uses.

- Applications: Ideal for general sealing, insulation, and moisture protection. It’s commonly used in HVAC systems, packaging, and automotive industries where flexibility is essential.

Hard Aluminum Foil:

- Characteristics: Offers higher strength and durability compared to soft aluminum foil. It is more rigid and resistant to tearing.

- Applications: Suitable for applications that require rigidity and tear resistance, such as structural reinforcement, industrial wrapping, and protective covering.

2. Laminated Foil

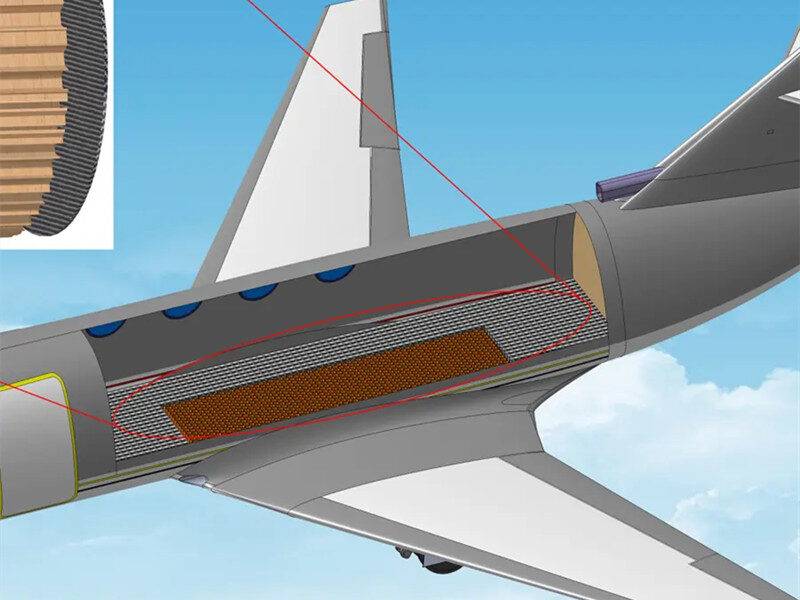

Aluminum Foil-Glass Cloth Laminate:

- Characteristics: Combines the reflective properties of aluminum with the strength and heat resistance of glass cloth.

- Applications: Perfect for high-temperature insulation and heat shielding in industries like aerospace and automotive, where thermal management is crucial.

Aluminum Foil-PET Laminate:

- Characteristics: The addition of a polyester (PET) layer provides extra durability and tear resistance.

- Applications: Used extensively in automotive and industrial settings for applications requiring robust and durable insulation materials.

Aluminum Foil-Paper Laminate:

- Characteristics: Offers increased flexibility and ease of use due to the combination of foil and paper.

- Applications: Commonly used in packaging and lightweight applications where flexibility and ease of handling are important.

3. Reinforced Foil

Foil-Scrim-Kraft (FSK):

- Characteristics: Features a reinforcement of scrim and kraft paper, enhancing its strength and durability.

- Applications: Widely used in HVAC and construction for insulation and vapor barriers, providing both structural integrity and moisture resistance.

Foil-Scrim-Film (FSF):

- Characteristics: Utilizes a film layer instead of kraft paper, offering improved moisture resistance.

- Applications: Ideal for high-humidity environments where moisture control is critical.

4. Coated Foil

Coated Aluminum Foil Tape:

- Characteristics: Coated with a protective layer such as polyethylene (PE) or acrylic, enhancing resistance to chemicals, moisture, and UV radiation.

- Applications: Designed for outdoor applications and harsh environments, such as sealing and protecting outdoor equipment.

5. Embossed Foil

Embossed Aluminum Foil:

- Characteristics: Features a textured surface to improve grip and conformability.

- Applications: Often used in applications that require a secure seal and easy handling, such as packaging, HVAC systems, and automotive parts.

6. Composite Foil

Aluminum Foil with Non-woven Fabric:

- Characteristics: Combines the flexibility and sound-damping properties of non-woven fabric with the reflective and protective properties of aluminum foil.

- Applications: Used in automotive and industrial settings for sound insulation and vibration dampening.

Aluminum Foil with Foam:

- Characteristics: Laminated with foam to provide enhanced insulation and cushioning properties.

- Applications: Ideal for HVAC and construction applications requiring thermal and acoustic insulation.

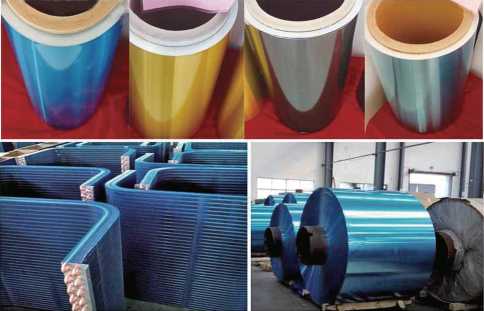

7. Colored Foil

Colored Aluminum Foil:

- Characteristics: Coated with colored pigments or dyes for aesthetic purposes and easy identification.

- Applications: Used in packaging and decorative applications to enhance visual appeal and brand differentiation.

By understanding these classifications based on backing material, you can choose the right aluminum foil tape for your specific requirements, ensuring optimal performance in your application.

Classification By Applications

Aluminum foil tape is classified by its applications based on the specific requirements and environments in which it is used. Here are the primary classifications by application:

1. HVAC Applications

Duct Sealing Tape: Used to seal joints and seams in ductwork to prevent air leaks, improve efficiency, and maintain system integrity.

Insulation Tape: Applied to insulate ducts, pipes, and other HVAC components, providing thermal insulation and moisture protection.

2. Electrical Applications

EMI/RFI Shielding Tape: Used to shield electronic devices from electromagnetic interference (EMI) and radio-frequency interference (RFI).

Grounding Tape: Provides electrical grounding and continuity in electrical systems, ensuring safety and performance.

3. Construction and Building

Vapor Barrier Tape: Used to create vapor barriers in walls, roofs, and floors to prevent moisture infiltration and improve energy efficiency.

Sealing Tape: Seals joints, seams, and gaps in construction materials, providing moisture resistance and structural integrity.

4. Automotive and Aerospace

Heat Shield Tape: Used in high-temperature areas to protect components from heat and improve thermal insulation.

Reflective Insulation Tape: Provides reflective insulation in automotive and aerospace applications, reducing heat buildup and improving comfort.

5. Packaging

Tamper-Evident Seals: Used to secure packages and provide evidence of tampering, ensuring product safety and integrity.

Reflective Packaging: Provides reflective properties for packaging, protecting contents from heat and light.

6. Marine Applications

Waterproof Sealing Tape: Used in marine environments to seal joints and seams, providing waterproofing and corrosion resistance.

Anti-Corrosion Tape: Protects metal surfaces from corrosion and rust in harsh marine conditions.

7. General Purpose

Repair and Maintenance Tape: Used for general repairs, maintenance, and patching of various materials and surfaces.

Craft and DIY Projects: Applied in arts, crafts, and DIY projects for decorative and functional purposes.

8. Thermal Insulation

High-Temperature Insulation Tape: Used in applications requiring thermal insulation and heat resistance, such as furnaces and kilns.

Cryogenic Insulation Tape: Provides insulation in low-temperature applications, preventing heat transfer and condensation.

9. Sound and Vibration Damping

Soundproofing Tape: Used to reduce noise and vibrations in automotive, industrial, and construction applications.

By understanding these classifications based on applications, you can select the appropriate aluminum foil tape for your specific needs, ensuring optimal performance and durability.

Benefits of Using Aluminum Foil Tape

Aluminum foil tape offers several advantages over other materials:

- Cost-effective: It’s a budget-friendly solution for various tasks.

- Easy to Use and Apply: The user-friendly design allows for quick and simple application.

- Durable and Long-Lasting: Depending on the type, aluminum foil tape can withstand wear and tear for extended periods.

- Heat and Moisture Resistant: Its properties make it ideal for use in environments with fluctuating temperatures or moisture.

- Conductive Tape Offers Good Electrical Conductivity: Conductive foil tape provides a reliable path for electrical current.

Get Quality Aluminum Foil Tape from CHAL

For those in need of high-quality aluminum foil tape, CHAL is a reliable and trusted supplier. CHAL offers a wide range of aluminum foil tapes designed to meet the diverse needs of various industries. With a commitment to quality and customer satisfaction, CHAL ensures that you get the best products for your applications.

In conclusion, aluminum foil tape is an indispensable tool in many industries due to its versatility, durability, and excellent properties. Whether you need it for sealing, insulating, or electrical applications, aluminum foil tape provides a reliable solution. Choose CHAL for your aluminum foil tape needs and experience the benefits of using top-quality products.