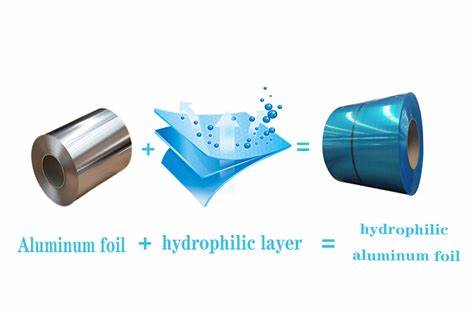

As a lightweight metal material, aluminum foil occupies an important position in the field of thermal insulation due to its unique physical structure and chemical stability. Its core value lies in its ability to achieve efficient thermal management through multiple mechanisms (such as heat reflection, low radiation, and barrier conduction). With the increasing demand for energy conservation and environmental protection, the application scenarios of aluminum foil have expanded from traditional packaging to high-tech fields such as building energy conservation, industrial insulation, and aerospace. The following article will focus on analyzing its thermal insulation properties and explore its specific applications in various fields.

Insulation Properties of Aluminum Foil

Aluminum foil’s effectiveness as a thermal insulator stems from three primary properties: high thermal reflectivity, low emissivity, and its barrier properties.

Thermal Reflectivity

One of the most significant properties of aluminum foil is its high thermal reflectivity. Aluminum foil can reflect up to 95% of radiant heat, making it an excellent choice for applications that require heat retention or deflection. Radiant heat transfer occurs through electromagnetic waves, and aluminum foil effectively minimizes this by bouncing the heat back towards its source or away from a protected area.

For example, in building insulation, aluminum foil is often used in radiant barriers within walls or attics to prevent excessive heat gain during summer and heat loss during winter. This reflective ability reduces energy consumption for heating and cooling, making it both an environmentally friendly and cost-effective solution.

By utilizing its reflective properties, aluminum foil provides a simple yet highly efficient way to control thermal energy transfer.

Low Emissivity

Emissivity measures a material’s ability to emit thermal radiation. Aluminum foil has an exceptionally low emissivity, meaning it emits very little heat energy compared to other materials. This property complements its thermal reflectivity, further enhancing its effectiveness as an insulator.

For instance, in spacecraft and high-temperature industrial settings, aluminum foil is used in multi-layer insulation (MLI) to regulate temperatures. The low emissivity prevents the transfer of heat through radiation, ensuring thermal stability in extreme environments.

By combining low emissivity with high reflectivity, aluminum foil provides unparalleled efficiency in thermal insulation applications.

Barrier Properties

Another critical feature of aluminum foil is its excellent barrier properties. Aluminum foil is impermeable to air, moisture, and light, which helps maintain the desired thermal conditions. This makes it particularly useful for applications that require protection from external environmental factors.

For example, in food packaging, aluminum foil serves as a barrier to prevent heat, moisture, and light from affecting the contents. Similarly, in building insulation, it acts as a shield against humidity and air infiltration, which can otherwise compromise thermal efficiency.

The barrier properties of aluminum foil enhance its insulating capabilities by offering comprehensive protection against various external influences.

Applications Based on Insulation Properties

The specific applications of aluminum foil insulation are directly linked to its inherent properties.

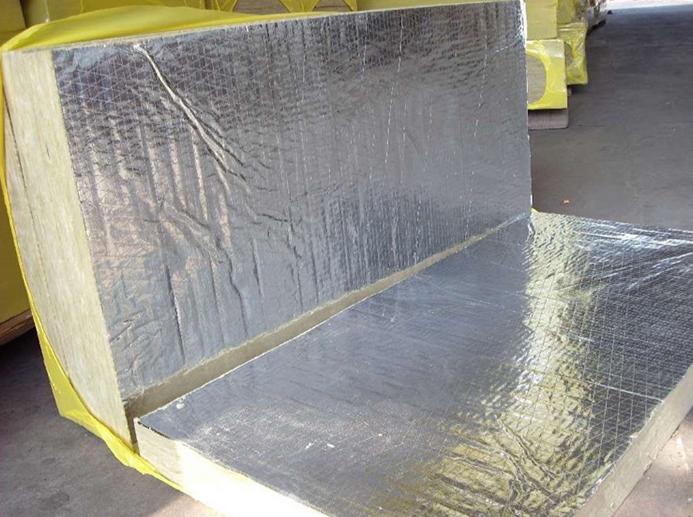

Building and Construction

In the construction industry, aluminum foil is commonly used as part of radiant barriers and insulation layers in walls, roofs, and attics. Its ability to reflect radiant heat and act as a vapor barrier helps improve energy efficiency in homes and commercial buildings. By reducing heat transfer, aluminum foil contributes to lower energy costs and improved comfort.

One case show that a commercial building in Dubai uses aluminum foil-PET composite film to reduce air conditioning energy consumption by 40%, saving 1.2 million kWh of electricity per year. Aluminum foil XPS board increases the floor heating heating speed by 50% and the thermal efficiency by 30%.

Food and Beverage Packaging

Aluminum foil’s combination of thermal reflectivity and barrier properties makes it ideal for food packaging. It helps maintain the temperature of food items, keeping them warm or cool as required. Aluminum foil lunch boxes can keep hot food warm for up to 4 hours (200% longer than plastic containers). Additionally, its barrier properties prevent the infiltration of moisture and air, preserving the freshness and quality of food products.

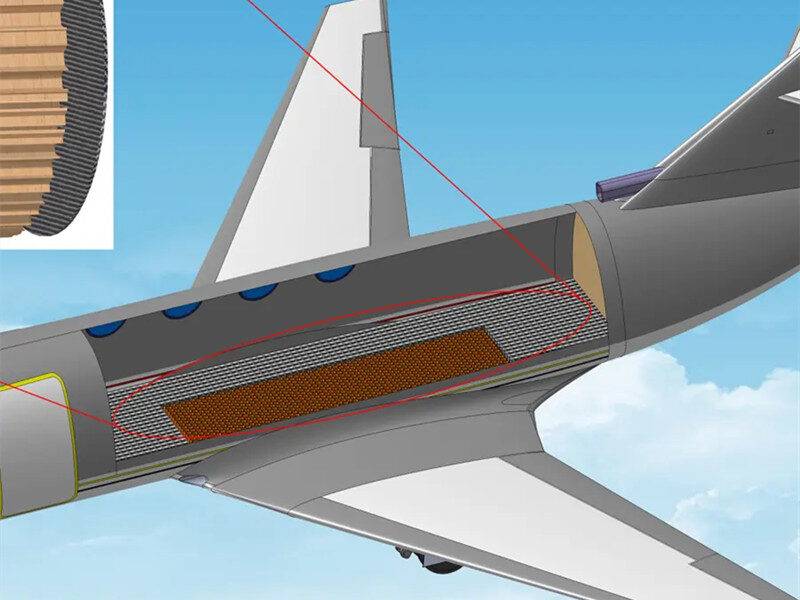

Aerospace and High-Temperature Applications

In aerospace engineering, aluminum foil is used in multi-layer insulation systems for spacecraft. These systems rely on the foil’s low emissivity and high reflectivity to maintain stable temperatures in the extreme conditions of space. Its lightweight nature and excellent insulating properties make it an essential material for such high-tech applications.

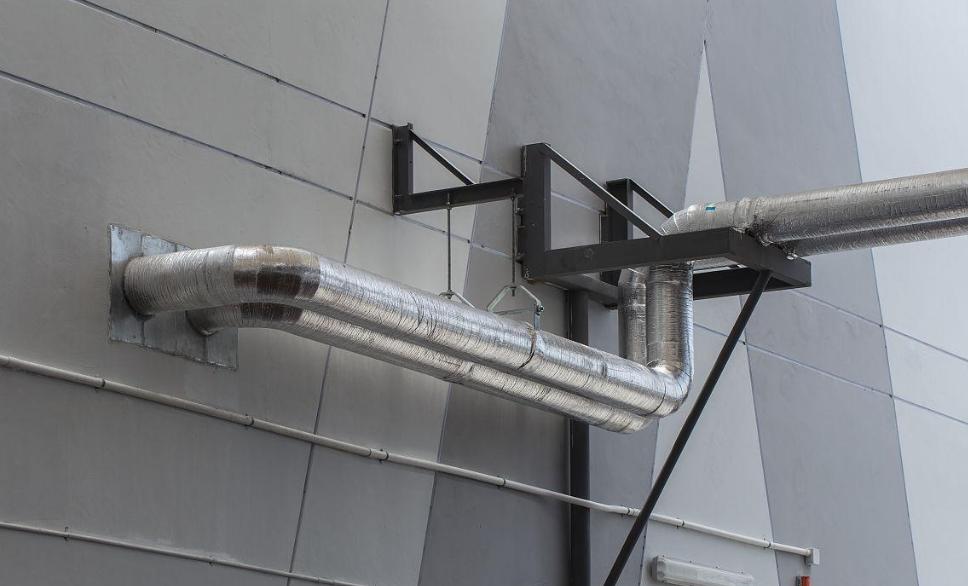

HVAC and Industrial Uses

In HVAC systems, aluminum foil is used to wrap ducts and pipes, preventing heat loss or gain and improving overall system efficiency.

In industrial settings, it is used to insulate machinery and equipment operating at high temperatures, ensuring safety and energy conservation. In piping insulation, it protects pipes from heat loss and condensation in plumbing and industrial systems. Multi-layer aluminum foil vacuum insulation board (VIP) makes heat loss <5 W/m², saving 500,000 yuan/km of steam cost per year.

Consumer and Emergency Products

Everyday items like insulated bags and emergency blankets also benefit from aluminum foil’s insulating properties. These products rely on its lightweight, reflective nature to retain or deflect heat, serving practical purposes in daily life and emergency scenarios. Mountaineering tents use aluminum foil coated fabrics, and the internal temperature at night is 8–10℃ higher than the environment, provide insulation in temporary shelters.

Advantages and Limitations of Aluminum Foil Insulation

Like any material, aluminum foil insulation has its pros and cons.

Advantages of Aluminum Foil Insulation:

- High Effectiveness: As discussed, its reflectivity and low emissivity provide excellent insulation against radiant heat.

- Cost-Effectiveness: Aluminum foil is relatively inexpensive compared to some other insulation materials.

- Ease of Installation: It’s lightweight and easy to handle, making it relatively simple to install.

- Durability: Aluminum foil is resistant to corrosion and degradation, ensuring long-term performance.

- Vapor Barrier: It acts as an effective vapor barrier, preventing moisture problems.

Limitations of Aluminum Foil Insulation:

- Air Gap Requirement: To maximize its effectiveness, aluminum foil needs an air gap, which can sometimes be challenging to create.

- Susceptibility to Damage: Thin aluminum foil can be easily creased, dented, or torn, reducing its effectiveness.

- Not Structural: Aluminum foil provides no structural support.

- Limited Conductive Insulation: Aluminum foil alone is not effective at insulating against conductive heat transfer. It often needs to be combined with other materials, like foam or fiberglass, for comprehensive insulation.

- Heat Retention Challenges: While it reflects heat well, it may not retain heat effectively without additional layers.

Weighing these advantages and limitations is crucial for determining the suitability of aluminum foil for a given application.

Aluminum foil’s unique combination of high reflectivity, low emissivity, and barrier properties makes it a versatile and effective thermal insulation material. From keeping homes comfortable and food fresh to protecting sensitive electronics and spacecraft, its applications are diverse. While it has some limitations, the advantages of aluminum foil insulation, particularly its effectiveness against radiant heat, cost-effectiveness, and ease of use, make it a valuable tool in managing thermal energy across a wide range of industries and applications.