Aluminum housing has become a critical component in various industries due to its unique properties such as lightweight, durability, corrosion resistance, and excellent thermal and electrical conductivity. These attributes make aluminum housing an ideal choice for protecting sensitive components and ensuring the longevity and reliability of various products. This article explores the top 10 applications of aluminum housing, highlighting how this versatile material is employed across different sectors.

1. Electronics and Telecommunications

In the electronics and telecommunications industries, aluminum housing is extensively used to protect sensitive electronic components. Devices such as servers, routers, power supplies, and communication equipment are often enclosed in aluminum.

The benefits of using aluminum in these applications are significant. Its excellent thermal conductivity helps dissipate heat efficiently, preventing overheating and prolonging the lifespan of electronic devices. Additionally, aluminums ability to provide electromagnetic shielding ensures that devices are protected from external electromagnetic interference (EMI), which is crucial for maintaining the integrity of electronic signals.

2. Consumer Electronics

Aluminum has become a hallmark of quality and durability in the consumer electronics market. High-end products like smartphones, laptops, and tablets often feature aluminum casings.

The benefits of aluminum in consumer electronics are numerous. Aluminums heat dissipation properties help maintain optimal operating temperatures, ensuring that the devices function efficiently even during heavy use. Additionally, aluminums durability ensures that these products can withstand drops, impacts, and other forms of physical stress, thereby extending the lifespan of the devices. The sleek, modern appearance of aluminum, combined with its lightweight nature, makes it ideal for portable devices that need to be both functional and stylish.

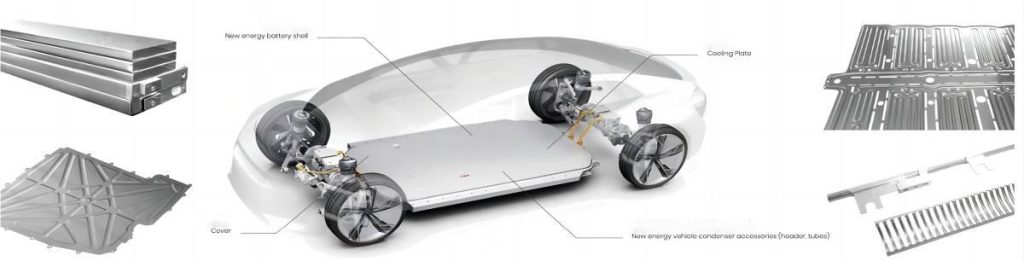

3. Automotive Industry

In the automotive industry, aluminum housing is used in various components, including engine parts, transmission cases, and battery enclosures for electric vehicles. Automotive manufacturers have increasingly turned to aluminum to meet the demands of modern vehicle design, where performance and environmental impact are closely linked.

The lightweight nature of aluminum helps reduce the overall weight of vehicles, which is crucial for improving fuel efficiency and reducing emissions. But the benefits of using aluminum in the automotive industry extend beyond weight reduction. Aluminums high strength-to-weight ratio ensures that automotive components are not only lighter but also durable enough to withstand the harsh conditions of vehicle operation. Additionally, aluminums resistance to corrosion plays a vital role in extending the lifespan of automotive parts, reducing the need for frequent replacements and maintenance. This combination of durability and efficiency makes aluminum an ideal material for modern automotive engineering.

4. Lighting Industry

Aluminum housings play a crucial role in the lighting industry, particularly in the design and manufacture of LED lights.

The benefits of using aluminum in lighting are substantial. LEDs generate significant amounts of heat, and effective thermal management is essential to maintain their brightness and extend their lifespan. Aluminum is often used in the housings of these lights because of its superior heat dissipation capabilities, ensuring that the lights remain cool and operate efficiently. Additionally, aluminums resistance to environmental factors, such as moisture and dust, makes it an ideal material for both indoor and outdoor lighting applications. This ensures that the lights remain durable and reliable, regardless of where they are installed, providing long-lasting illumination.

5. Aerospace and Aviation

In the aerospace and aviation industries, aluminum is the material of choice for various housing applications, including avionics, engine components, and structural parts.

The benefits of aluminum in aerospace and aviation extend beyond its lightweight nature. Aluminums resistance to corrosion is crucial in high-altitude environments, where exposure to extreme conditions can compromise the integrity of materials. By using aluminum housings, manufacturers can ensure that aircraft components remain durable and reliable throughout their service life. This contributes to the overall safety and efficiency of aircraft, making aluminum an indispensable material in the aerospace sector.

6. Marine Industry

Aluminum is widely used in the marine industry for housing applications, including marine electronics, engines, and other equipment that must withstand the harsh marine environment.

The benefits of using aluminum in the marine industry are significant. Its resistance to corrosion extends the lifespan of marine equipment, reducing the need for frequent maintenance and replacements. Aluminum housings are essential for protecting critical marine components from rust and deterioration, ensuring that they remain functional and reliable. Additionally, aluminums lightweight properties contribute to the overall buoyancy and fuel efficiency of vessels, making it a preferred material in marine engineering.

7. Medical Devices

In the medical field, aluminum housing is commonly used in devices such as diagnostic equipment, surgical tools, and monitoring systems.

The benefits of aluminum in medical devices are multifaceted. The material’s non-toxic nature, combined with its resistance to corrosion, makes it suitable for healthcare applications. Aluminum housings protect sensitive medical components and ensure that devices are easy to sterilize, which is essential for maintaining hygiene and preventing contamination in medical environments. Its lightweight yet sturdy construction allows for easy handling and transport of medical devices, which is especially important in emergency and surgical settings. Additionally, aluminums excellent heat dissipation properties ensure that medical equipment operates within safe temperature ranges, preventing malfunctions and ensuring accurate performance. These characteristics make aluminum a critical material in the design of reliable and efficient medical devices.

8. Renewable Energy

The renewable energy sector relies heavily on aluminum housing for various components, particularly in solar and wind power systems. In solar energy, aluminum is used to construct enclosures for inverters and other electrical equipment, protecting them from environmental factors such as rain, dust, and extreme temperatures. In wind turbines, aluminum housings are used for components that require lightweight yet strong materials to ensure the efficiency and stability of the turbines.

The benefits of using aluminum in renewable energy applications are considerable. Aluminums durability and corrosion resistance make it an ideal material for housing critical components in renewable energy systems, where long-term performance and reliability are essential. Additionally, aluminums lightweight nature contributes to the efficiency of renewable energy systems, helping to reduce overall costs and improve the sustainability of energy production. These factors make aluminum housing a key component in the advancement of renewable energy technologies.

9. Industrial Equipment

In industrial settings, aluminum housing is used to protect machinery and equipment, including pumps, motors, and control systems. Industrial environments often expose equipment to extreme conditions, such as high humidity, dust, or chemicals. Aluminum is chosen for its ability to withstand these harsh conditions while providing reliable protection for critical industrial components.

The benefits of aluminum in industrial equipment are clear. Its strength and resistance to corrosion ensure that the equipment remains protected and functional, even in challenging environments. Additionally, aluminums lightweight nature allows for easier installation and maintenance of industrial equipment, reducing downtime and operational costs. This combination of durability and ease of use makes aluminum a preferred material in the construction of industrial housings.

10. Robotics and Automation

As robotics and automation continue to advance, the demand for durable and lightweight materials for housings has increased. Aluminum is widely used in the construction of robotic arms, automation systems, and other related equipment.

The benefits of aluminum in robotics and automation are significant. The material’s lightweight properties enable faster and more efficient movement of robotic components, while its strength ensures the durability and longevity of the systems. Aluminums resistance to environmental factors, such as dust, moisture, or chemicals, makes it suitable for use in various industrial settings where robots may be exposed to harsh conditions. Additionally, the materials ability to dissipate heat effectively ensures that robotic systems remain cool and operate efficiently, enhancing their overall performance and reliability.

Conclusion

Aluminum housing plays a crucial role in a wide range of industries, from consumer electronics to aerospace and renewable energy. CHAL can providing the raw materials to made Aluminum housing. Please feel free to contact our sale to get a nice quote.