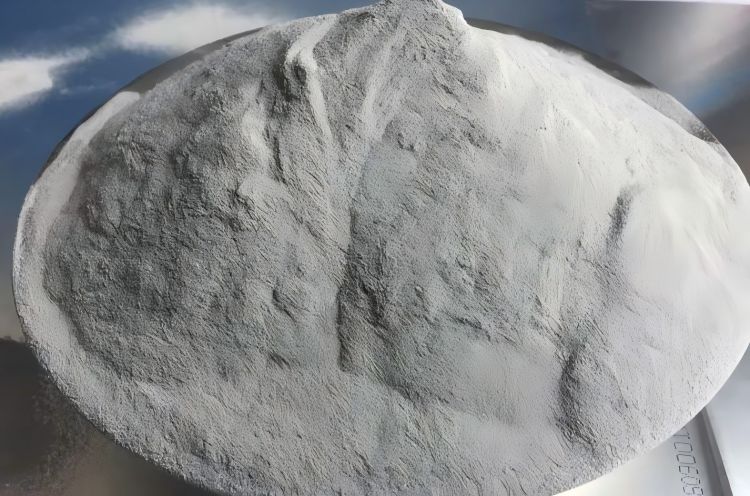

Aluminum paste, a unique material composed of finely ground aluminum powder mixed with a binder, offers a combination of metallic luster, reflectivity, conductivity, and chemical stability. These attributes make it an indispensable component in industries ranging from coatings and electronics to energy and aerospace. This article explores the numerous aluminum paste uses and highlights its significance in modern manufacturing and technology.

1. Aluminum Paste in the Coatings and Printing Industry

The coatings and printing industries are significant consumers of aluminum paste due to its ability to impart a metallic sheen and enhance the durability of coatings. Below are the primary applications:

A. Automotive, Motorcycle, and Bicycle Coatings

- Widely used in paints for cars, motorcycles, and bicycles.

- Provides a brilliant metallic finish, enhancing the visual appeal of vehicles.

- Offers protective properties, improving corrosion resistance and extending the lifespan of paint under harsh conditions.

- Particularly sought after in luxury vehicles for aesthetic purposes.

B. Plastics and Architectural Coatings

- Utilized in coatings for plastic products and architectural structures.

- Added to paints in the construction industry to provide decorative effects and improved durability.

- Ideal for exterior coatings, protecting buildings from UV radiation and weathering.

- Enhances the appearance of plastics by imparting a metallic finish, making it popular for high-end consumer products.

C. Inks

- Used to create specialized inks for decorative printing processes.

- Produces metallic effects on paper, plastics, and other substrates.

- The high reflectivity and brightness of aluminum make these inks ideal for eye-catching prints, particularly in packaging and advertising materials.

2. Aluminum Paste in the Electronics Industry

The electronics industry leverages aluminum paste for its conductive properties, which are crucial in the production of various electronic components. Key applications include:

A. Conductive Adhesives

- Used in the assembly of electronic devices, particularly in the manufacture of printed circuit boards (PCBs).

- Facilitates the connection of electronic components, ensuring efficient electrical pathways.

- High conductivity of aluminum is critical for the proper functioning of electronic circuits.

- Known for reliability and durability, making it ideal for a wide range of electronic products.

B. Conductive Inks

- Employed in the production of flexible electronics and other electronic components.

- Enables printing of conductive tracks on various substrates, allowing for lightweight and flexible electronic circuits.

- Supports the creation of cost-effective and high-performance electronic devices.

- Increasingly used in industries such as consumer electronics, healthcare, and wearable technology.

3. Aluminum Paste in Metal Products

The metal products industry benefits from aluminum paste’s ability to enhance both the protective and aesthetic qualities of coatings used on metal surfaces. Applications include:

A. Industrial Metal Coatings

- Applied to metal surfaces to improve resistance to corrosion, oxidation, and other forms of degradation.

- Provides a protective barrier that shields metal from environmental factors, extending product lifespan.

- Adds a metallic finish, enhancing the aesthetic appeal of metal products.

B. Marine Coatings

- Key ingredient in coatings used on ships, offshore platforms, and other marine structures.

- Offers excellent resistance to corrosion in harsh marine environments, including saltwater, high humidity, and UV exposure.

- Reflective properties of aluminum help reduce heat absorption, contributing to the longevity and performance of marine structures.

C. Heat-Resistant Coatings

- Used in industries such as power generation, metallurgy, and automotive manufacturing, where surfaces are exposed to high temperatures.

- Enhances the heat-reflective properties of coatings, protecting underlying metal and maintaining structural integrity.

4. Aluminum Paste in Building Materials

The construction industry has innovatively incorporated aluminum paste into various building materials, focusing on applications that enhance reflectivity and energy efficiency:

A. Reflective Roofing Materials:

- Utilized in coatings for roofs to reduce heat accumulation by reflecting sunlight away from the building.

- Helps maintain cooler interior temperatures, reducing the need for air conditioning.

- Contributes to improved energy efficiency in buildings.

B. Reflective Wall Coverings:

- Applied in wall coverings to minimize heat gain by reflecting sunlight.

- Enhances indoor comfort by keeping interior spaces cooler.

- Supports sustainable building practices through energy conservation.

C. Reflective Flooring Materials:

- Integrated into flooring materials to reduce heat absorption.

- Aids in maintaining a comfortable indoor environment.

- Contributes to the overall energy efficiency of buildings.

5. Aluminum Paste in Fireworks Manufacturing

Aluminum paste is a crucial component in the pyrotechnics industry, where it enhances both the brightness and stability of fireworks:

A. Brightness Enhancement:

- Used to produce bright and intense flashes of light during firework displays.

- The aluminum particles react with oxygen to create a brilliant white light, a key feature of many fireworks.

B. Combustion Stability:

- Contributes to stabilizing the combustion process, ensuring consistent and safe burning.

- Essential for producing high-quality, reliable pyrotechnic products.

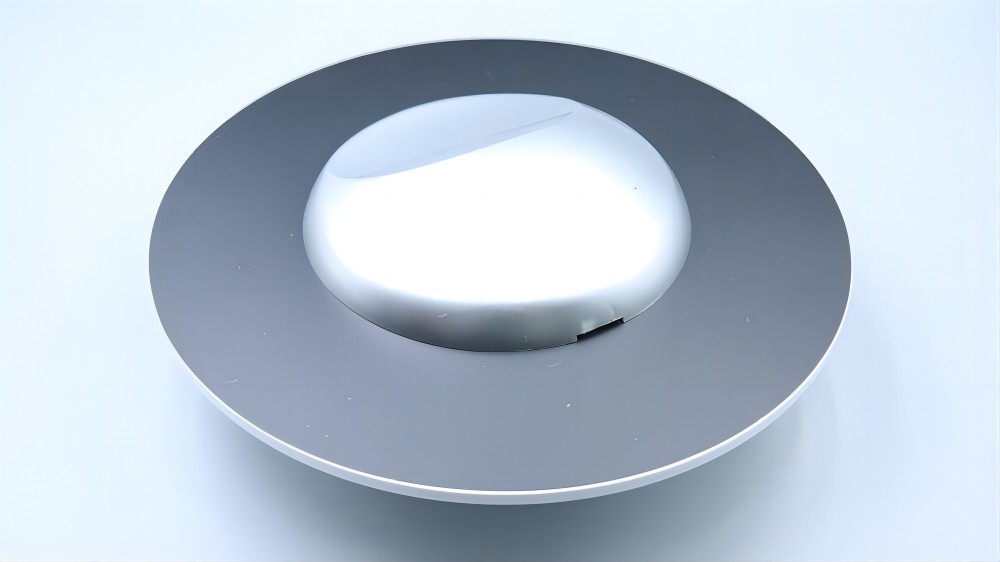

6. Aluminum Paste in Energy Sector Applications

The energy sector has effectively utilized aluminum paste in the development of solar energy technologies, particularly in solar panels:

A. Solar Panel Efficiency:

- Applied as a reflective layer on the back of solar cells to improve light absorption.

- Enhances the efficiency of photovoltaic cells in converting sunlight into electricity.

B. Durability and Protection:

- Provides additional protection to solar panels, improving resistance to environmental factors such as moisture and UV radiation.

- Contributes to the longevity and performance of solar panels, supporting the advancement of renewable energy solutions.

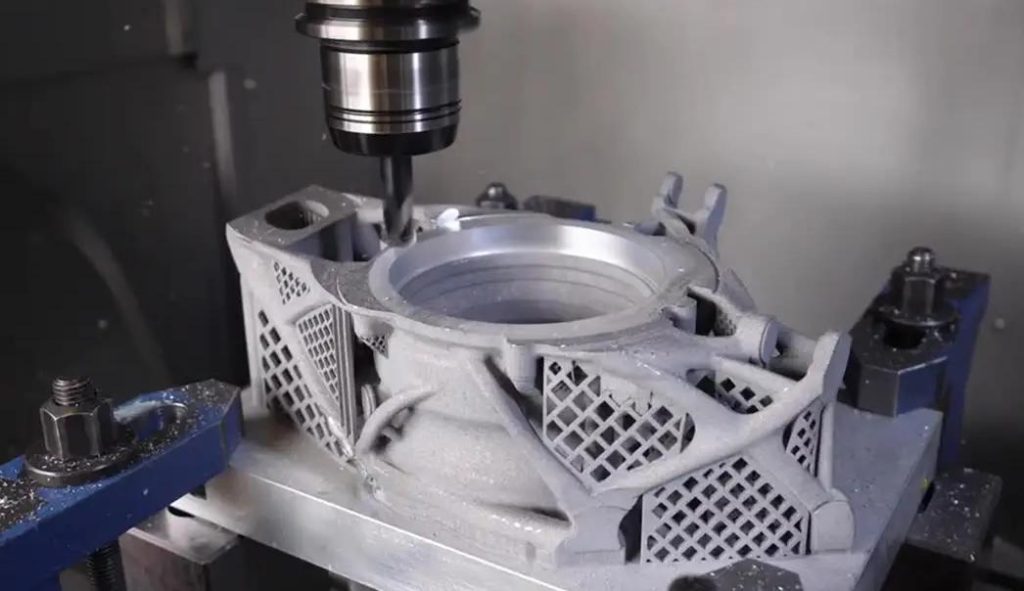

7. Aluminum Paste in Aerospace Industry Use

The aerospace industry highly values aluminum paste for its lightweight and high-strength characteristics, which are essential in the design and manufacturing of advanced aerospace components:

A. Structural Components for Spacecraft:

- Used in the production of lightweight structural components, crucial for improving fuel efficiency and payload capacity.

- Applied in coatings and adhesives to bond or protect these components, ensuring reliability in the extreme conditions of space.

- High reflectivity aids in managing thermal loads, protecting spacecraft from intense solar heat.

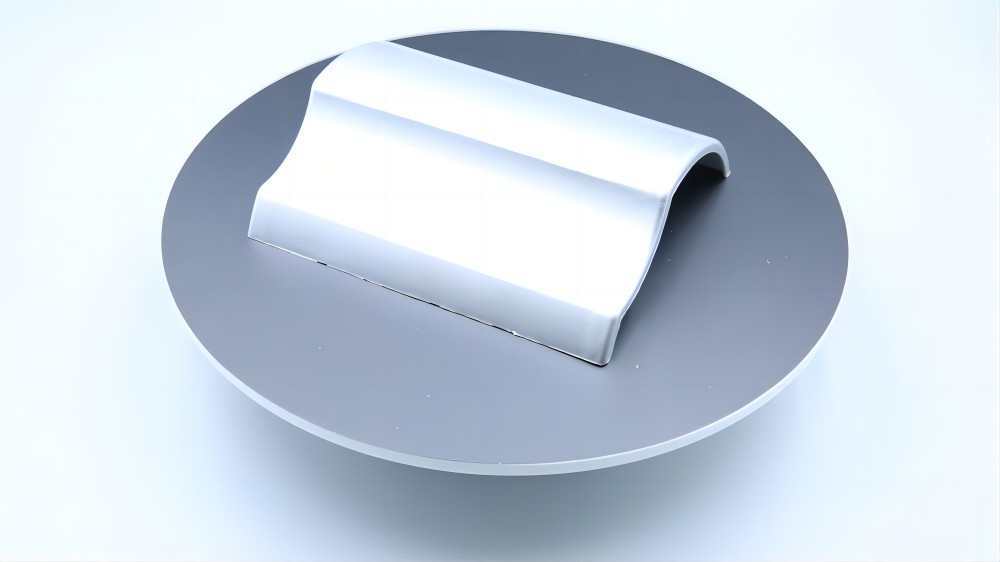

B. Brake Systems for High-Speed Vehicles:

- Utilized in the development of brake systems for aircraft and performance cars, where effective heat dissipation is critical.

- High thermal conductivity of aluminum helps prevent brake system overheating, ensuring consistent performance.

- Lightweight properties contribute to reducing overall vehicle weight, enhancing speed and fuel efficiency.

8. Aluminum Paste in Nanotechnology

As technology advances, aluminum paste is gaining potential applications in the emerging field of nanotechnology, particularly in developing high-performance materials and medical applications:

A. Pharmaceutical Applications:

- Explored for use in drug delivery systems, where nanoscale aluminum particles can target specific cells or tissues.

- High surface area and reactivity make aluminum nanoparticles suitable for improving treatment effectiveness and minimizing side effects.

B. Electronic Devices:

- Leveraged in developing advanced electronic devices, where nanoscale aluminum particles enhance electrical and thermal conductivity.

- Contributes to creating high-performance materials for microchips, power electronics, and other next-generation electronic components, improving device efficiency and performance.

In general, the diverse applications of aluminum paste benefit from the physical and chemical properties of aluminum powder, such as high reflectivity, good conductivity, and chemical stability. As the demand for advanced materials continues to grow, the uses of aluminum paste are likely to expand further, driven by ongoing innovations and technological advancements.