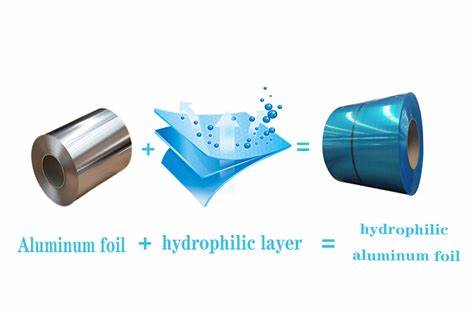

Waterproof aluminium tape is a versatile and indispensable material across various industries. Known for its durability and resistance to environmental factors, this tape has become a go-to solution for sealing, repairing, and protecting surfaces. Whether in construction, automotive, or HVAC systems, waterproof aluminium tape offers unparalleled performance. This article delves into its key properties, industrial applications, advantages, and considerations for selecting the right tape for your needs.

Key Properties of Waterproof Aluminium Tape

Waterproof aluminium tape owes its popularity to a combination of essential properties that make it suitable for demanding industrial applications.

- Durability: The tape’s aluminium backing resists wear and tear, ensuring long-lasting performance even under extreme conditions.

- Waterproofing: Its waterproof adhesive effectively seals surfaces against moisture, preventing corrosion and damage.

- Temperature Resistance: The tape can withstand extreme temperatures, making it ideal for applications in both high-heat and freezing environments.

- UV Resistance: Its ability to resist UV rays ensures it maintains its integrity when exposed to sunlight for extended periods.

- Strong Adhesion: The adhesive bonds securely to various surfaces, including metal, plastic, and concrete, ensuring a tight and reliable seal.

These properties make waterproof aluminium tape a versatile and practical choice for industrial purposes. Understanding its capabilities helps industries maximize its benefits.

Top Industrial Uses of Waterproof Aluminium Tape

Waterproof aluminium tape finds applications in numerous industries due to its adaptability and reliability.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, aluminium tape is crucial for:

- Sealing Ductwork: Preventing air leaks and enhancing system efficiency.

- Insulation: Providing thermal protection and reducing energy loss.

- Moisture Protection: Protecting ductwork from corrosion and mold caused by humidity.

By maintaining airtight seals, the tape reduces energy costs and extends the lifespan of HVAC components.

Construction and Building Maintenance

Waterproof aluminium tape is widely used in construction for:

- Roof Repairs: Sealing leaks and cracks to prevent water ingress.

- Joint Sealing: Waterproofing joints and seams in walls and windows.

- Surface Protection: Shielding materials from environmental damage.

Its durability and ease of application make it a cost-effective solution for maintaining building integrity.

Automotive Industry

In automotive applications, the tape serves purposes such as:

- Temporary Repairs: Sealing damaged panels and components.

- Insulating Wires: Protecting electrical connections from water and heat.

- Noise Reduction: Damping vibrations and minimizing noise.

This tape’s resilience ensures reliable performance even in challenging driving conditions.

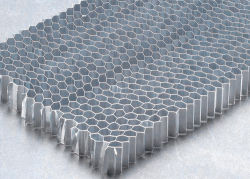

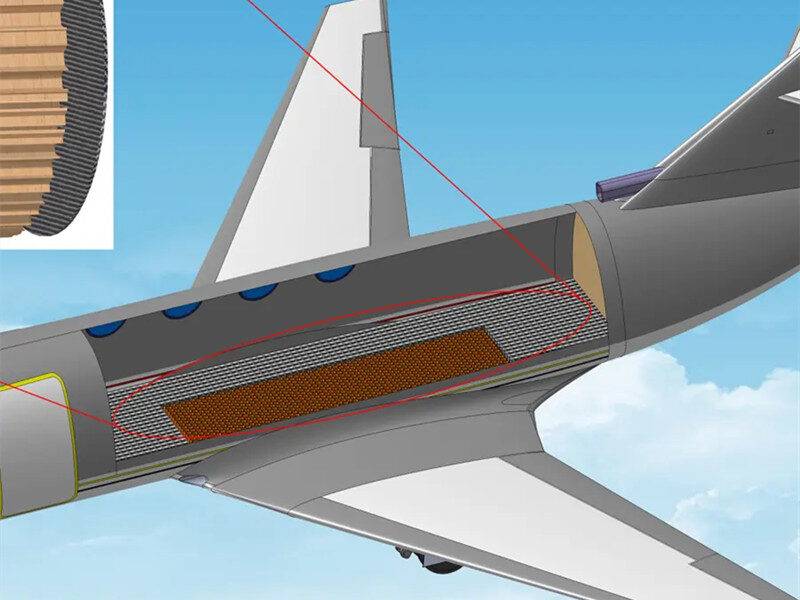

Aerospace Applications

Aerospace demands high-performance materials, and aluminium tape delivers:

- Thermal Protection: Insulating components against extreme temperatures.

- Moisture Barriers: Preventing water damage in sensitive areas.

- Structural Repairs: Offering a quick fix for minor issues during operations.

Its lightweight nature and robustness align with the stringent requirements of this industry.

Marine Industry

In the marine sector, waterproof aluminium tape is vital for:

- Sealing Hulls: Preventing leaks and protecting against saltwater corrosion.

- Protecting Electrical Systems: Shielding wires and connectors from moisture.

- Deck Repairs: Addressing minor damages to maintain vessel safety.

Its ability to withstand harsh marine environments ensures optimal performance and durability.

Electronics and Electrical Work

Waterproof aluminium tape is frequently used in electronics and electrical systems for:

- Cable Insulation: Shielding wires from moisture and physical damage.

- EMI Reduction: Minimizing electromagnetic interference.

- Sealing Connections: Protecting joints from water ingress.

This tape enhances safety and reliability in electrical installations.

Packaging and Storage

In packaging and storage, aluminium tape is effective for:

- Waterproof Sealing: Ensuring packages remain moisture-free.

- Reinforcement: Strengthening boxes and containers for transport.

- Long-Term Storage: Protecting sensitive items from environmental exposure.

Using waterproof aluminium tape offers several benefits that make it indispensable in industrial applications:

- Cost Efficiency: Reduces repair and maintenance expenses.

- Ease of Application: Simple to use, saving time and labor.

- Versatility: Applicable across various industries and surfaces.

- Enhanced Longevity: Extends the lifespan of equipment and structures by preventing damage.

- Environmentally Resistant: Performs reliably in challenging conditions such as extreme temperatures, humidity, and UV exposure.

These advantages make it an essential tool for industries aiming to improve efficiency and reduce costs.

Considerations for Choosing the Right Tape

Selecting the right waterproof aluminium tape is crucial to ensure optimal performance and durability in your application. Below are detailed considerations to guide your choice:

1. Thickness

The tape’s thickness directly impacts its durability and flexibility. For heavy-duty applications, such as sealing HVAC ducts or repairing roofs, opt for thicker tapes that offer enhanced strength and protection. For applications requiring pliability, such as wrapping irregular surfaces, a thinner tape may be more suitable.

2. Adhesive Strength

A high-quality adhesive is critical for ensuring the tape bonds securely to the intended surface. Consider the surface material (e.g., metal, plastic, concrete) and environmental conditions. Tapes with industrial-grade adhesives perform well in demanding situations and provide long-lasting seals.

3. Temperature Resistance

Check the tape’s temperature tolerance to ensure it can withstand the environmental conditions of your application. For example, in HVAC systems or automotive applications exposed to extreme heat or cold, a tape with a wide temperature range is essential to prevent failure.

4. Moisture and UV Resistance

If the tape will be used outdoors or in humid environments, ensure it is designed to resist moisture and UV rays. This ensures that the tape maintains its integrity and adhesion over time, even when exposed to challenging weather conditions.

5. Surface Compatibility

Not all tapes adhere equally well to all surfaces. Verify that the chosen tape is compatible with the material you’re working with. Some tapes are specifically designed for metals, while others may work better on plastics or wood.

6. Ease of Application

Consider whether the tape is easy to handle and apply. Features such as a peel-off backing or flexibility can make installation quicker and more efficient, especially for large-scale projects or complex surfaces.

7. Brand Reputation and Certifications

Choose a tape from a reputable brand known for quality and reliability. Look for certifications or performance standards that verify the tape’s suitability for your specific application, such as UL or ASTM standards.

8. Cost vs. Performance

While cost is a factor, it’s important to prioritize performance and durability. Investing in a high-quality tape may save costs in the long run by reducing the need for repairs or replacements.

By carefully evaluating these factors, you can select the right waterproof aluminium tape that meets the demands of your application, ensuring durability, efficiency, and long-term satisfaction.

Waterproof aluminium tape is a versatile, reliable, and cost-effective solution for a wide range of industrial applications. From sealing ducts to repairing roof leaks, its robust properties make it indispensable across industries. By understanding its benefits and selecting the right tape for each application, businesses can enhance efficiency, reduce maintenance costs, and ensure the longevity of their assets. Invest in high-quality waterproof aluminium tape to meet your industrial challenges with confidence.