In modern electrical engineering, cable wires play a crucial role, functioning as the lifelines of power transmission. Among them, aluminum cable wire has emerged as a vital component due to its distinct advantages. This article provides a comprehensive guide on the types, applications, benefits, and challenges of aluminum cable wire, offering valuable insights into its usage in various industries.

Types of Aluminum Cable Wires

Aluminum cable wires can be classified in several ways based on different criteria:

1. Classification By Conductor Material:

- Pure Aluminum Cable Wires: These wires use pure aluminum as the conductor, offering excellent electrical conductivity but relatively lower mechanical strength. They are suitable for applications where mechanical strength is not a critical factor, such as indoor wiring.

- Aluminum Alloy Cable Wires: These wires are made by adding small amounts of other metals like magnesium and silicon to pure aluminum, resulting in an alloy conductor. Aluminum alloy cables maintain good conductivity while significantly improving mechanical strength and corrosion resistance, making them widely used in various applications requiring enhanced durability.

2. Classification By Insulation Material:

- PVC Insulated Cable Wires: These wires use polyvinyl chloride (PVC) as the insulating material. They are cost-effective, easy to manufacture, and widely used in general environments for power transmission.

- XLPE Insulated Cable Wires: Cross-linked polyethylene (XLPE) is used as the insulating material in these wires. They offer excellent high-temperature resistance, electrical performance, and mechanical strength, making them ideal for high-temperature, high-voltage, or reliability-critical applications.

- Other Special Insulation Materials: These include silicone rubber and mineral insulation, which provide unique benefits tailored for specialized applications such as extreme environments or fire-resistant wiring.

3. Classification By Structure:

- Single-Core Cable Wires: These consist of a single conductor and an insulation layer, making them simple and suitable for low-current applications.

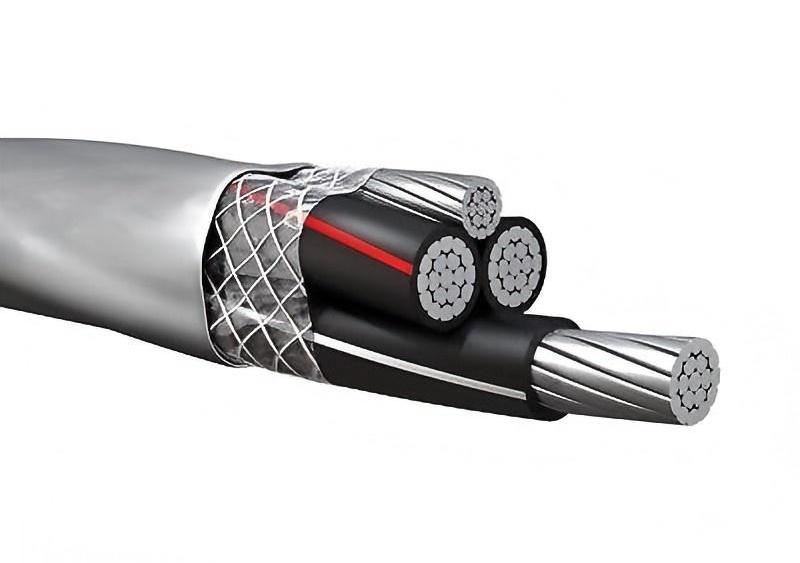

- Multi-core Cable Wire: Comprising multiple conductors and insulation layers, multi-core cables can carry multiple circuits simultaneously, making them ideal for high-current or multi-circuit systems.

- Armored Cable Wire: With an additional metal armor layer for protection, these cables offer enhanced mechanical strength and resistance to environmental hazards, making them suitable for harsh environments.

4. Classification By Application:

- Power Cable Wires: Used for transmitting and distributing electrical energy, these are the most common type of cable wires in power systems.

- Control Cable Wires: These are used for transmitting control signals and are widely used in automated control systems.

- Communication Cable Wires: Used for information transmission, such as telephone lines and network cables.

Applications of Aluminum Cable Wires

Aluminum cable wires are widely used across various fields due to their unique advantages:

1. Application in Power Systems:

- Transmission Lines: In high-voltage and ultra-high-voltage transmission projects, aluminum cable wire is preferred for its lightweight nature and cost-effectiveness.

- Distribution Networks: Aluminum cables are increasingly replacing copper cables in urban and rural power distribution networks.

- Substations: These cables interconnect electrical equipment within substations to facilitate power conversion and distribution.

2. Application in Building Electrical Systems:

- Indoor Wiring: Aluminum cable wire is used in residential and commercial buildings for lighting, power outlets, and other electrical connections.

- Power Supply for Elevators and Air Conditioners: Large electrical appliances such as elevators and air conditioners rely on aluminum cables for stable power delivery.

3. Application in Industrial:

- Power Supply for Factories and Workshops: Aluminum cables are used for main and branch power lines in factories and workshops to meet the power demands of production equipment.

- Connecting Machinery and Automation Systems: These cables connect various machinery and automated control systems, enabling power and signal transmission.

4. Application in Transportation:

- Railway and Metro Power Supply: Aluminum cables are used in the power traction systems of railways and metros to provide the necessary power for train operations.

- Marine and Aviation Electrical Systems: These cables are used in ships and aircraft to reduce weight and improve energy efficiency.

5. Application in Renewable Energy:

- Wind and Solar Power Projects: Aluminum cables are used for power output and transmission in wind and solar power projects.

Advantages and Challenges of Aluminum Cable Wires

Aluminum cable wires offer several advantages in electrical engineering:

- Lightweight: Aluminum has a lower density than copper, making aluminum cable wire nearly half the weight of its copper counterpart. This feature simplifies installation and reduces structural load.

- Cost-effective: Aluminum is significantly cheaper than copper, making aluminum cable wire a cost-efficient solution for large-scale electrical projects.

- Good Conductivity: Although aluminum’s conductivity is slightly lower than that of copper, it is sufficient for general electrical needs. In applications where high conductivity is not critical, aluminum cables can replace copper cables, reducing costs.

However, aluminum cable wires also face some challenges:

- Lower Mechanical Strength: Aluminum is less mechanically robust than copper, making it more susceptible to damage. Therefore, protective measures are necessary during installation.

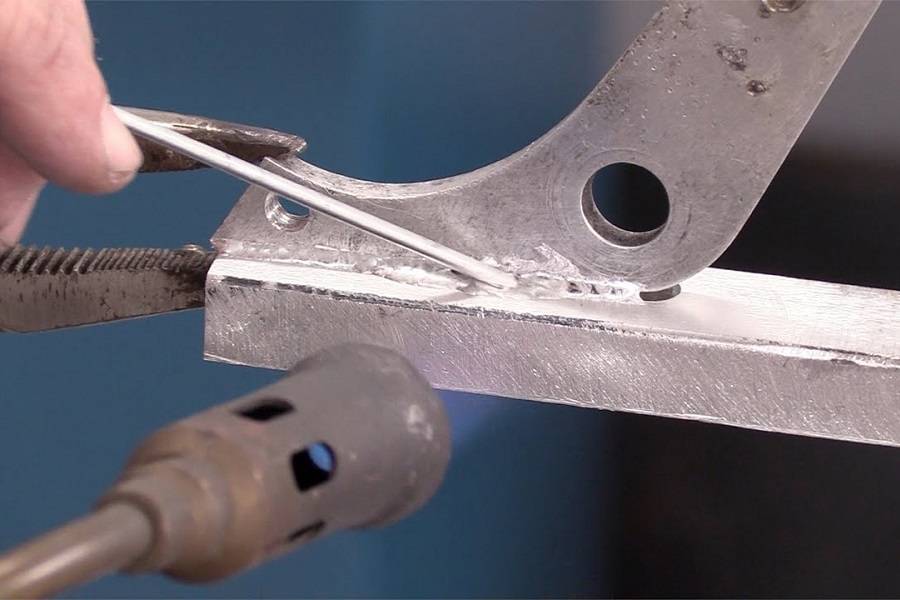

- High Connection Requirements: Aluminum forms an oxide layer on its surface, which can affect conductivity. Special connectors and techniques are required to ensure reliable connections.

- Long-Term Reliability: Issues such as creep and corrosion can affect the long-term performance of aluminum cable wire, necessitating rigorous maintenance and monitoring.

Key Takeways Summarize

Aluminum cable wire plays a vital role in electrical engineering, with applications spanning power distribution, building wiring, industrial usage, transportation, and renewable energy. Its advantages, including lightweight construction, cost-effectiveness, and good conductivity, make it an attractive alternative to copper cables.

However, the challenges associated with aluminum cable wire, such as lower mechanical strength and complex connection requirements, must be carefully addressed to ensure safe and efficient operation. When selecting aluminum cable wire, it is crucial to consider factors such as application scenarios, current capacity, voltage levels, and environmental conditions.

With advancements in technology, aluminum cable wire continues to evolve, offering improved performance and broader application prospects. As the demand for energy efficiency and cost reduction grows, aluminum cable wire is expected to play an increasingly significant role in future electrical systems, contributing to sustainable development and modern infrastructure advancements.