Aluminum pigments are among the most valued ingredients in creating metallic effects in a wide range of products. From automotive coatings to decorative packaging, these pigments enhance both visual appeal and performance across industries. Their shimmering, metallic effect can transform a surface’s look, making them indispensable in paints, inks, plastics, and even cosmetics. However, aluminum pigments come in various forms—water-based aluminum paste, aluminum pigment, and aluminum pigment paste—each suited to specific applications and bringing unique benefits.

This article explores the world of aluminum pigments, focusing on understanding their different types, characteristics, applications, and interrelationships.

What Are Aluminum Pigments?

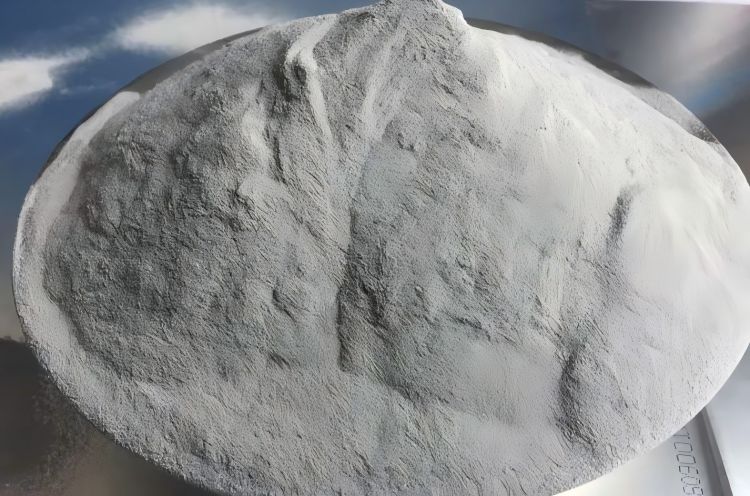

Aluminum pigments are a type of metallic pigment made from finely milled aluminum flakes. When these flakes are dispersed in mediums like paint or ink, they align parallel to the surface. This alignment reflects light, creating a brilliant, metallic effect that can range from subtle pearlescence to a mirror-like shine. The final effect depends on the size, shape, and surface treatment of the aluminum flakes, which can be adjusted for desired performance and aesthetic outcomes.

Types of Aluminum Pigments

Aluminum pigments come in various forms, primarily based on the flake size, shape, and surface treatment.

1. Flake Size and Shape

- Fine Flake: Creates a soft, pearlescent effect often used for sophisticated, subtle finishes.

- Medium Flake: Strikes a balance between brightness and coverage, providing a versatile solution for many applications.

- Coarse Flake: Offers a high-gloss, mirror-like finish with strong reflectivity, often seen in high-impact coatings.

2. Surface Treatment

- Untreated: These flakes provide a bright, reflective finish but may be prone to oxidation, reducing their durability in certain environments.

- Size-Reduced: Processed to reduce particle size for improved dispersion and finer finishes, enhancing the smoothness and uniformity of the metallic effect.

- Surface-Treated: Treated for enhanced weatherability, corrosion resistance, and compatibility with various binders, making them more versatile in challenging environmental conditions.

Understanding the distinct properties of these aluminum pigment types allows manufacturers to tailor their formulations to meet specific aesthetic and performance requirements.

Applications of Aluminum Pigments

The unique visual and functional properties of aluminum pigments make them highly desirable across several industries:

1. Paints and Coatings

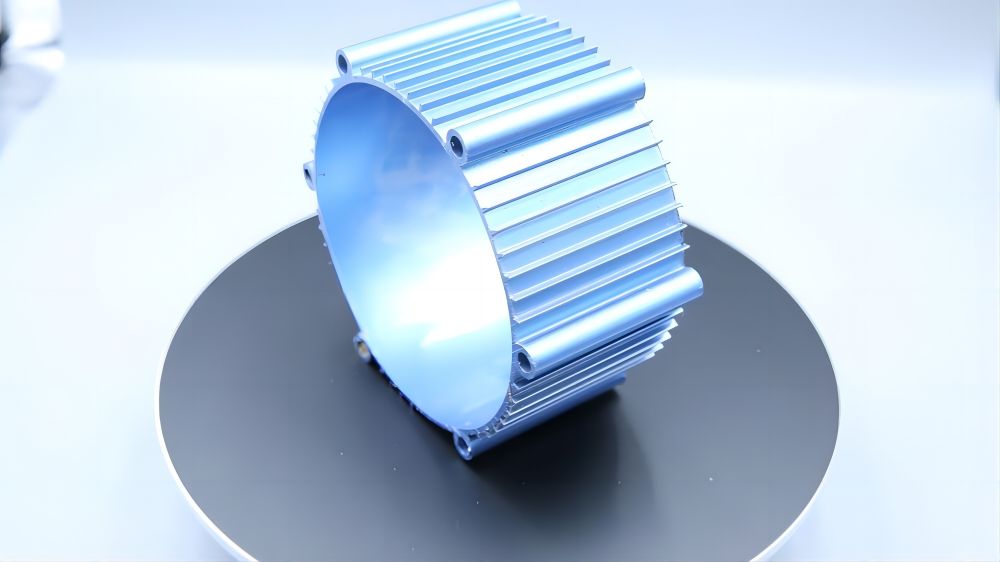

- Automotive Coatings: Aluminum pigments provide the striking, metallic effect seen in modern automotive finishes.

- Architectural Coatings: Used for metallic building finishes, adding a touch of elegance and durability to building exteriors.

- Industrial Coatings: Add both aesthetic appeal and protection to heavy-duty industrial machinery and equipment.

2. Inks and Printing

- Packaging Printing: Aluminum pigments bring a premium metallic sheen to product packaging, helping brands stand out on shelves.

- Security Printing: Aluminum pigments are used in security applications for anti-counterfeiting measures due to their unique reflective properties.

- Decorative Printing: Adds a shimmering effect to promotional materials, magazines, and decorative prints.

3. Plastics and Rubber

- Automotive Components: Adds metallic accents to interior and exterior car parts.

- Consumer Goods: Provides a high-end metallic finish on items such as electronics, kitchenware, and sporting goods.

- Industrial Applications: Used in parts and products that benefit from both visual appeal and functional durability.

4. Other Industries

- Cosmetics: Aluminum pigments create a shimmery effect in products like eyeshadow, lipstick, and nail polish.

- Ceramics: Adds a metallic finish to tiles and decorative ceramic items.

- Textiles: Used in creating fabrics with a metallic effect, often for fashion and interior design.

What is Water-Based Aluminum Paste?

Water-based aluminum paste is a form of aluminum pigment incorporated into a water-based carrier. This innovative product offers an environmentally friendly alternative to traditional solvent-based aluminum pastes, addressing concerns about VOC emissions and toxicity.

Advantages of Water-Based Aluminum Paste

- Reduced Environmental Impact: Water-based pastes minimize the release of volatile organic compounds (VOCs) into the environment, reducing air pollution and meeting regulatory standards.

- Improved Safety: These pastes are generally less flammable and toxic than their solvent-based counterparts, making them safer to store, handle, and transport.

- Lower Odor: With fewer solvent-based odors, water-based pastes are more pleasant to work with, especially in indoor environments or confined spaces.

Applications of Water-Based Aluminum Paste

- Water-Based Paints and Coatings: Ideal for both interior and exterior applications where low VOCs and reduced environmental impact are essential, including architectural and decorative coatings.

- Inks and Printing: Suitable for printing processes such as offset, flexographic, and gravure, making it a versatile choice for creating metallic effects on various printed materials.

What is Aluminum Pigment Paste?

Aluminum pigment paste is a flexible product combining aluminum pigment with a binding agent. This binding agent can be either solvent-based or water-based, allowing for easy dispersion, excellent coverage, and strong adhesion.

Types of Aluminum Pigment Pastes

- Leafing and Non-Leafing Aluminum Pastes

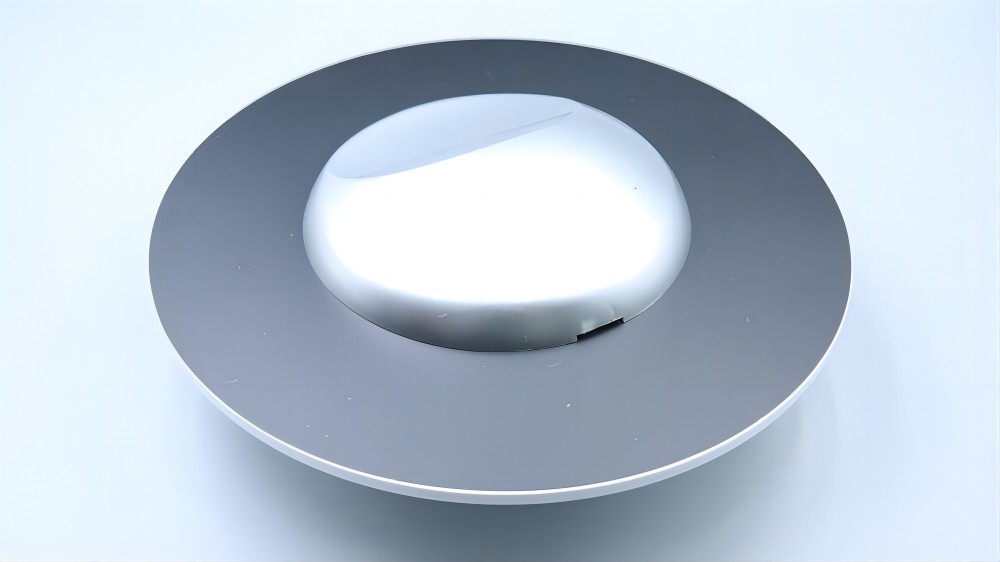

- Leafing Aluminum Pastes: The aluminum flakes align parallel to the surface, creating a highly reflective, metallic finish commonly used in applications that require high gloss and visual impact.

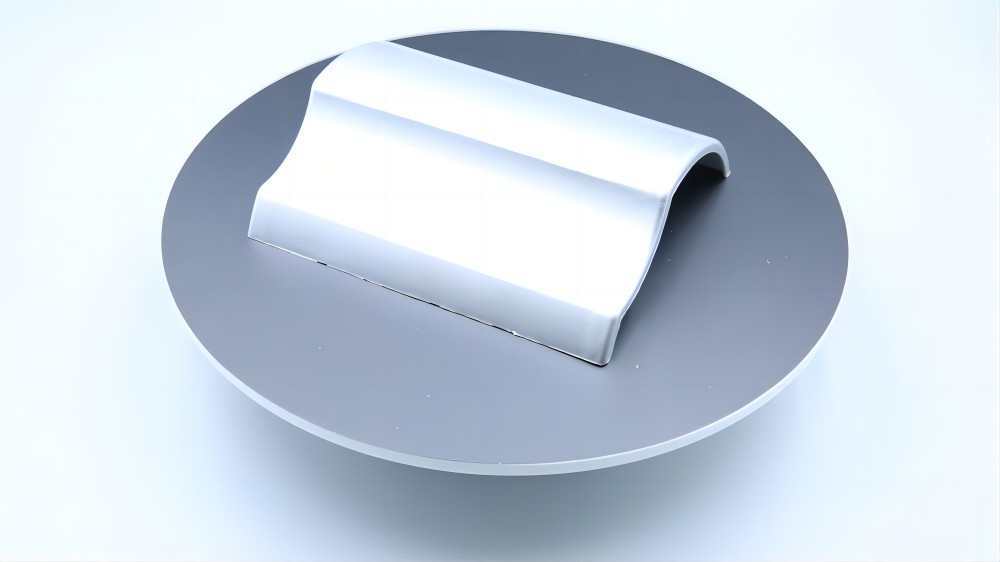

- Non-Leafing Aluminum Pastes: In these pastes, the aluminum flakes are randomly oriented, producing a more subtle, satin-like appearance suitable for applications where a subdued finish is desired.

- Solvent-Based and Water-Based Aluminum Pastes

- Solvent-Based Aluminum Pastes: Known for excellent performance and durability, though they may raise environmental concerns due to VOC emissions.

- Water-Based Aluminum Pastes: More environmentally friendly, providing a safer, lower-impact alternative with reduced VOCs.

Applications of Aluminum Pigment Paste

- Paints and Coatings: Widely used in automotive, architectural, and industrial coatings for both interior and exterior applications.

- Inks and Printing: Essential in creating metallic effects in packaging, security, and decorative printing applications.

- Plastics and Rubber: Provides metallic effects for various plastic and rubber products, often used in consumer goods and automotive components.

The Interplay Between Aluminum Pigment, Water-Based Aluminum Paste, and Aluminum Pigment Paste

To fully appreciate the relationship between these three products, it is essential to understand their unique roles in manufacturing:

- Aluminum Pigment: The raw material and fundamental building block of both water-based aluminum paste and aluminum pigment paste.

- Water-Based Aluminum Paste: A specialized formulation that incorporates aluminum pigment in a water-based carrier, suited for applications where environmental safety is a priority.

- Aluminum Pigment Paste: A more general category that includes both solvent-based and water-based formulations, each with unique advantages depending on the specific application.

Key Differences and Similarities

| Feature | Aluminum Pigment | Water-Based Aluminum Paste | Aluminum Pigment Paste |

| Form | Powder or flake | Paste | Paste |

| Carrier Medium | None | Water | Solvent or water |

| Environmental Impact | Low | Low | Varies (higher for solvent-based) |

| Application | Requires dispersion | Ready-to-use | Ready-to-use |

Choosing the Right Product

Choosing the appropriate aluminum-based product depends on several factors:

- Desired Metallic Effect: The intended look (e.g., bright vs. satin finish) can influence the choice of aluminum pigment type and formulation.

- Application Method: Certain products are more compatible with specific application methods, such as spraying, brushing, or dipping.

- Environmental Considerations: Water-based products are generally more eco-friendly, aligning with regulatory standards for VOC emissions and workplace safety.

- Cost-Effectiveness: Evaluating the product cost, including the pigment, carrier, and any additives, is essential in choosing a solution that fits both the budget and application needs.

Aluminum pigments, along with water-based aluminum pastes and aluminum pigment pastes, offer versatile options for creating impressive metallic effects. Understanding the nuances of each type allows manufacturers to make informed decisions, selecting the best product for both aesthetic and performance goals. As technology advances, we can expect even more innovative and sustainable aluminum-based products that will continue to drive the future of metallic finishes across industries.