In today’s world, where noise levels are constantly rising, the need for effective soundproofing solutions has become increasingly important. Aluminum fiber sound-absorbing panels have emerged as a versatile and efficient solution for a wide range of applications, from enhancing acoustics in studios and theaters to reducing noise pollution in urban environments. This article delves into the benefits, working principles, and various types of aluminum fiber sound-absorbing panels, providing a comprehensive overview of this innovative soundproofing technology.

What are the Benefits of Using Aluminum Fiber Sound-Absorbing Panels?

Aluminum fiber sound-absorbing panels offer a multitude of benefits that make them an attractive choice for noise reduction applications. These panels are:

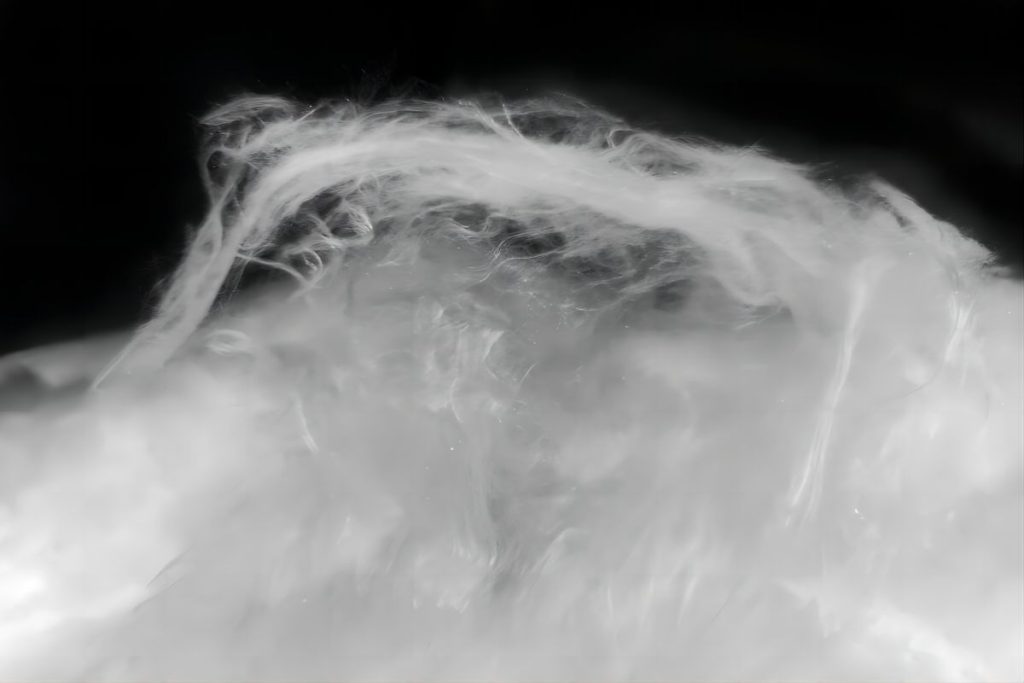

- Highly Effective Sound Absorption: Aluminum fibers possess a unique structure that effectively traps sound waves, converting them into heat energy. This results in significant noise reduction, particularly in mid-to-high frequency ranges, where human hearing is most sensitive.

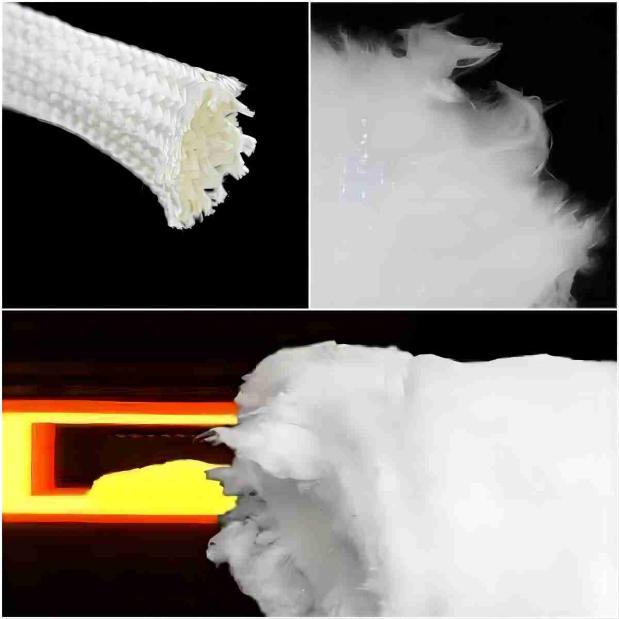

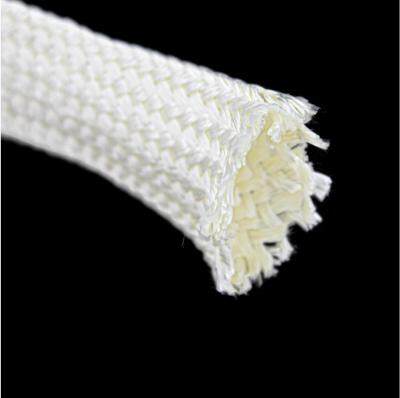

- Fireproof and Heat Resistant: Aluminum fibers are naturally fire-resistant, making them an ideal choice for applications where fire safety is paramount. These panels can withstand high temperatures without melting or releasing toxic fumes, ensuring safety in case of a fire.

- Waterproof and Moisture Resistant: Aluminum fibers are not affected by moisture, making them suitable for use in humid environments or areas prone to water exposure. This resistance to moisture prevents the growth of mold and mildew, maintaining the integrity of the panels over time.

- Lightweight and Easy to Install: Aluminum fiber sound-absorbing panels are lightweight, making them easy to handle and transport. Their installation process is straightforward, often requiring only basic tools and minimal expertise. This ease of installation reduces labor costs and allows for DIY projects.

- Aesthetically Pleasing: Aluminum fiber sound-absorbing panels come in a variety of colors and finishes, allowing them to blend seamlessly into any décor. They can be customized to match the aesthetic of a particular space, enhancing its visual appeal while improving acoustics.

- Environmentally Friendly: Aluminum is a recyclable material, and aluminum fiber sound-absorbing panels are often made from recycled aluminum content. This contributes to sustainable building practices and reduces the environmental impact of construction projects.

How do Aluminum Fiber Sound-Absorbing Panels Work?

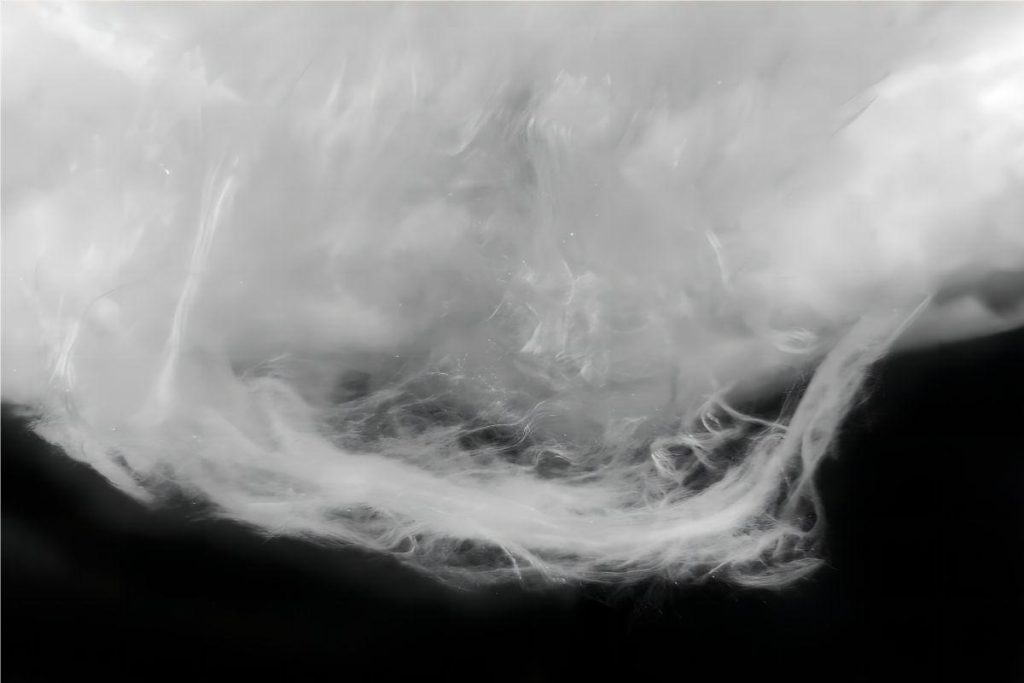

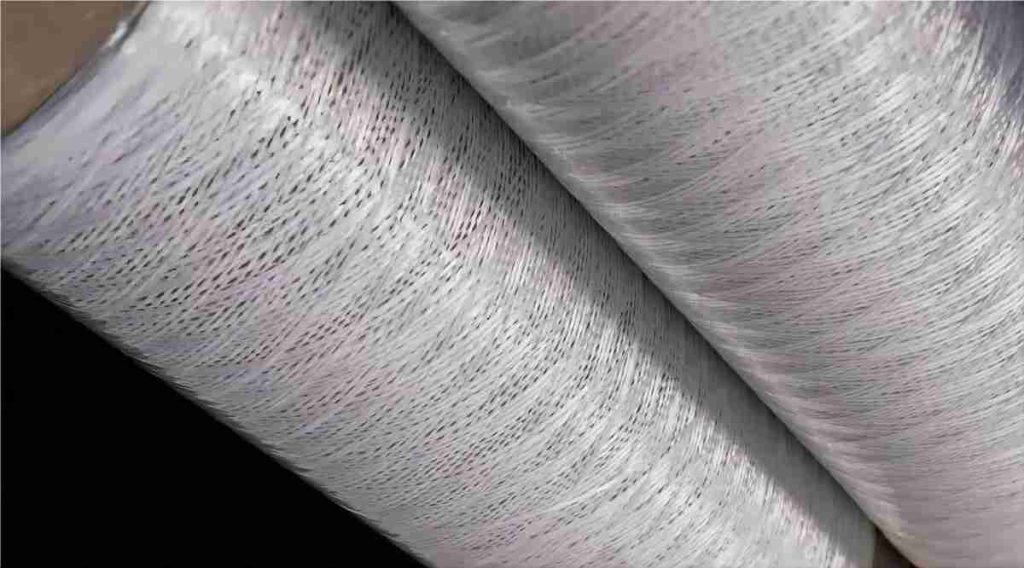

The effectiveness of aluminum fiber sound-absorbing panels lies in their unique ability to convert sound waves into heat energy. As sound waves encounter the porous structure of the panels, they are trapped and converted into vibrations within the fibers. These vibrations dissipate as heat, effectively reducing the energy of the sound waves and minimizing noise levels.

The sound absorption coefficient (SAC) is a measure of a material’s ability to absorb sound waves. Aluminum fiber sound-absorbing panels typically have an SAC of 0.7 or higher, indicating excellent sound absorption capabilities. Higher SAC values indicate greater sound absorption, making them suitable for controlling a wider range of frequencies.

What are the Different Types of Aluminum Fiber Sound-Absorbing Panels?

Aluminum fiber sound-absorbing panels are available in various forms and configurations to suit diverse applications. Some common types include:

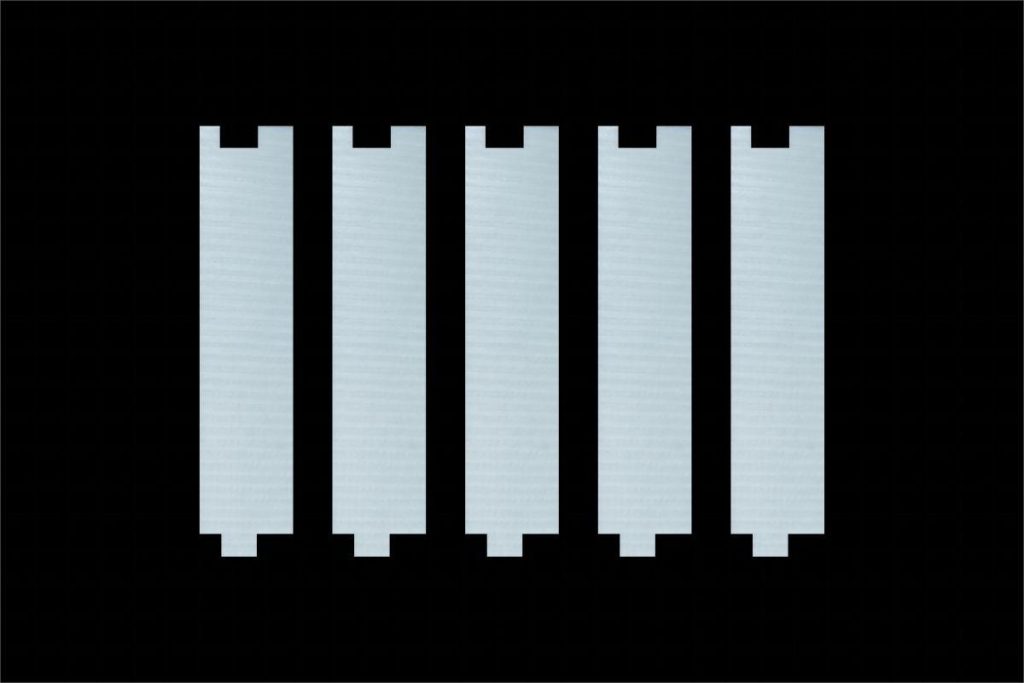

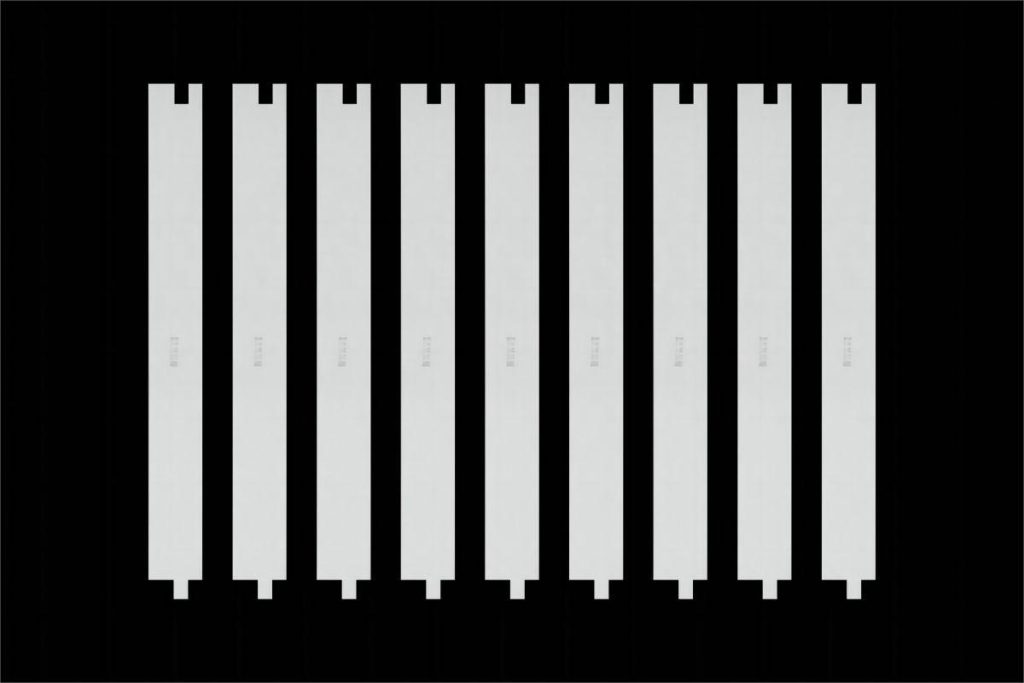

- Perforated Aluminum Fiber Panels: These panels feature a series of small holes or perforations that are strategically placed throughout the panel’s surface. These perforations act as acoustic waveguides, directing sound waves into the porous structure of the panel where they are effectively absorbed. This unique design allows perforated aluminum fiber panels to achieve higher sound absorption coefficients compared to unperforated panels, particularly for mid-to-high-frequency sounds.

- Unperforated Aluminum Fiber Panels: In contrast to perforated panels, unperforated aluminum fiber panels feature a solid, uniform surface without any holes or perforations. This design provides a more traditional and refined appearance, making them suitable for spaces where aesthetics and sound absorption are paramount. While unperforated panels may exhibit slightly lower sound absorption coefficients compared to perforated ones, they are still effective in absorbing low-to-mid-frequency sounds, making them a viable option for a wide range of applications.

- Aluminum Fiber Panels with Fabric Facings: To elevate the aesthetic appeal of aluminum fiber sound-absorbing panels, fabric facings can be applied to the panel’s surface. These facings come in a wide range of colors, textures, and patterns, allowing for customization to match any interior design. The fabric provides a decorative touch while maintaining the panel’s excellent sound absorption properties.

- Curved Aluminum Fiber Panels: Designed to seamlessly integrate with curved surfaces or architectural features, curved aluminum fiber panels are a unique and functional solution for sound absorption. Their flexible structure allows them to conform to various shapes, making them suitable for rounded walls, arches, and other curved elements. This flexibility ensures that sound absorption is maintained even in areas with unconventional geometries.

- Custom-Shaped Aluminum Fiber Panels: For applications where standard panel shapes are not suitable, custom-shaped aluminum fiber panels offer a tailored solution. These panels can be manufactured to specific dimensions and geometries, precisely fitting unique architectural features or specific installation requirements. This customization ensures that sound absorption is optimized for the specific application, ensuring maximum noise reduction.

Conclusion

Aluminum fiber sound-absorbing panels have emerged as a powerful tool in the fight against noise pollution. Their superior sound absorption properties, fire resistance, water resistance, and aesthetic appeal make them an ideal choice for a wide range of applications, from homes and offices to studios, theaters, and industrial settings. As the demand for effective noise control solutions continues to grow, aluminum fiber sound-absorbing panels are poised to play a pivotal role in creating quieter, healthier, and more acoustically comfortable environments.