Aluminum alloy materials are widely used in transportation, marine, aerospace, and other fields, especially in some lightweight key components in automobiles, aircraft, aerospace, ships, and other fields, aluminium alloy materials are irreplaceable, so let’s talk to you today Let’s talk about the difference between the categories of aluminum plates.

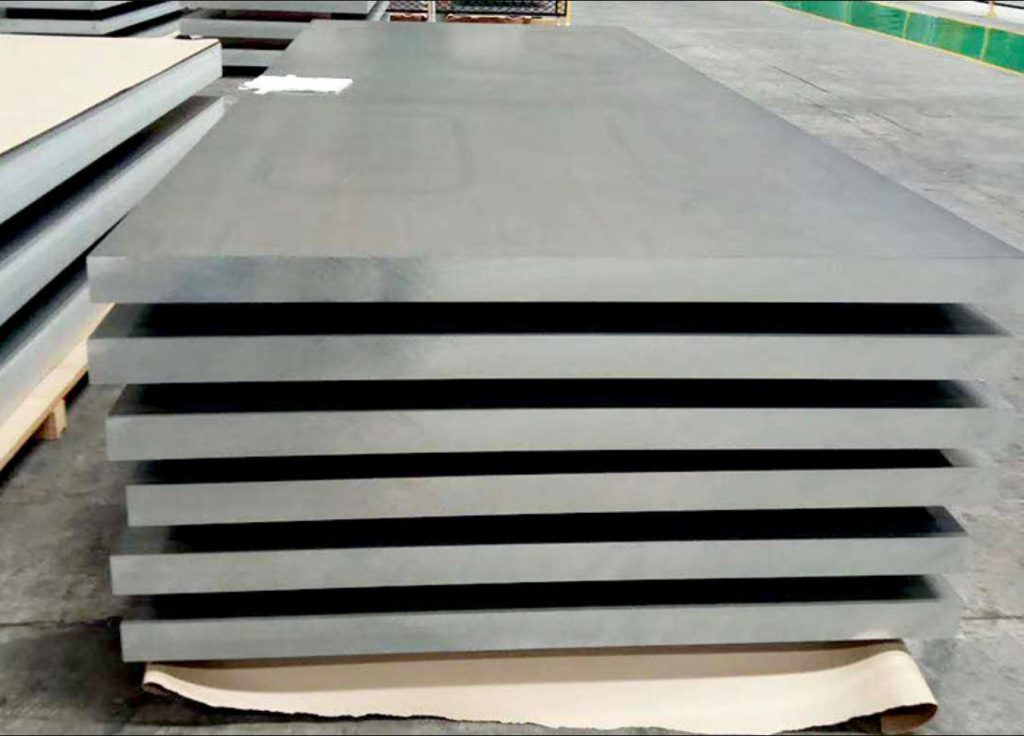

What kind of aluminum product is called aluminum plate?

The definition of an aluminum plate is to call aluminum material with a thickness of more than 0.2mm to less than 500mm, a width of more than 200mm, and a length of fewer than 16m of an aluminium plate or aluminum sheet.

0.2mm or less is aluminum sheet, and within 200mm width is row material or strip (of course, with the progress of large equipment, there are also many aluminium sheets with a maximum width of 600mm).

Another classification method of aluminum plate refers to the rectangular plate rolled and processed from aluminium ingot, which is divided into the pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium and thick aluminum plate, and patterned aluminum plate.

What are the types of aluminum plates? What are their characteristics?

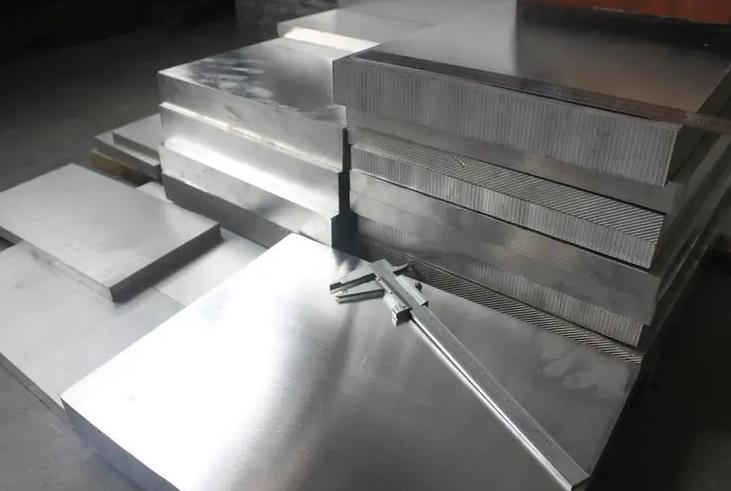

- Brushed aluminum plate

The manufacturing process of repeatedly scraping the aluminum plate out of lines with sandpaper. The main process of process is divided into 3 parts: de-esterification, sand mill and water washing.

In the aluminum plate drawing process, the special film technology after anodizing can make a film layer containing the metal component on the surface of the aluminum sheet, and clearly show every fine wire mark, so that the metal matte shines with fine hair. Silky sheen.

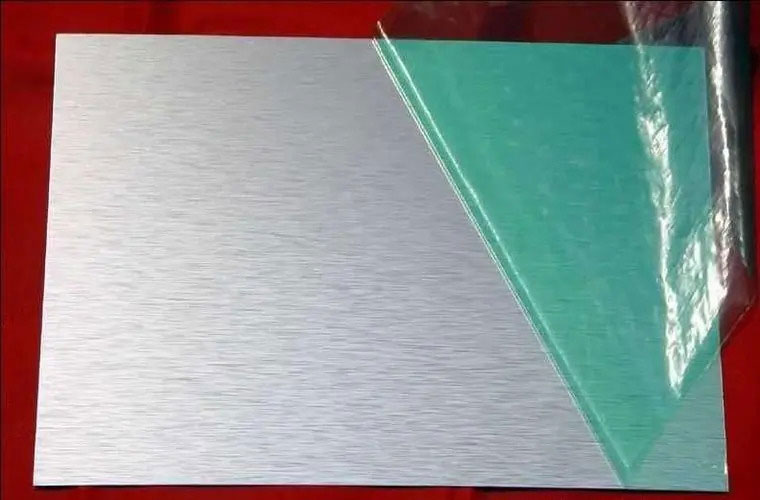

- Anodized aluminum plate

The aluminum plate is formed by placing the aluminum plate in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as the anode, and performing electrolysis under specific conditions and applied current.

The anodization of the aluminum plate forms a thin layer of aluminum oxide on the surface with a thickness of 5 to 20 microns, and the hard-anodized film can reach 60 to 200 microns.

- PS aluminum plate

Advertisement aluminum plate, also known as printed zinc plate, newspaper plate. That is an aluminIum plate with a printed pattern on the back and a thickness of 025 or 03.

- Mirror aluminum plate

Refers to the aluminum plate that is processed by rolling, grinding and other methods to make the surface of the plate show a mirror effect.

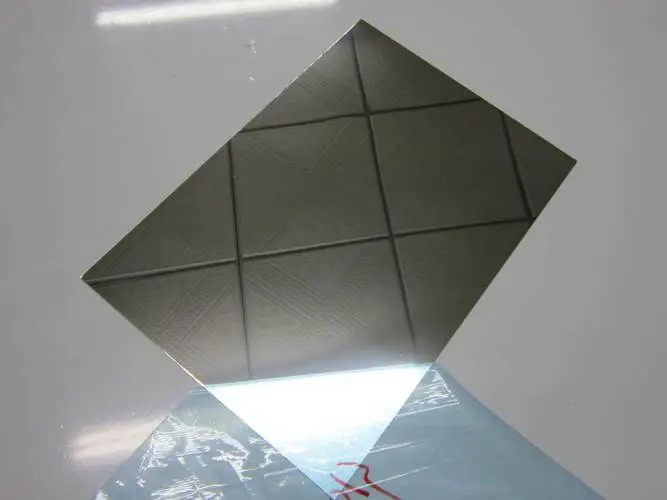

- Embossed aluminum plate

Also known as an aluminum embossed plate, a double-sided pattern, which belongs to aluminum products with various patterns formed on the surface after calendering based on the aluminum plate. It is widely used, mainly used in packaging, construction, curtain wall, etc.

- Patterned aluminum plate

One side with a pattern, which is made by rolling a steel rod with a concave and convex pattern.

The most common one on the market is the aluminIum plate with five-rib patterns. The five concave-convex patterns are arranged relatively parallel, and each pattern has an included angle of 60-80 degrees or 90 degrees perpendicular to other patterns, so this pattern has excellent anti-skid performance.

What kind of aluminum plate can CHAL provide you?

CHAL is a supplier specializing in aluminum plates. At CHAL you can find a variety of aluminum processing materials such as regular aluminum plates, anodized aluminum sheets, aluminum foils, and aluminum tubes with reliable performance. We provide high-quality aluminum materials to hundreds of companies around the world every year, and the safety and reliability of materials is the key factor for us to win market share.