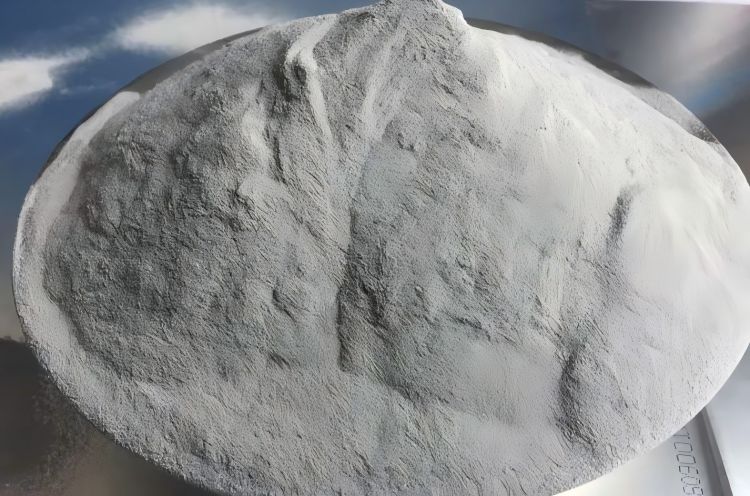

In the realm of pigments, water-based aluminum paste reigns supreme as a beacon of versatility and sustainability. Unlike its solvent-based brethren, it sheds the shackles of harmful VOCs and embraces the cleansing caress of water. This eco-conscious champion not only gleams with a metallic splendor but also boasts a surprising array of applications that span industries like art, construction, and even the alluring world of cosmetics. Let’s embark on a journey to unveil the secrets hidden within this shimmering water-based pigment paste, exploring its diverse talents and the unique viewpoints it lends to each field.

Shielding and Shining: The Two Faces of Aluminum in Paints and Coatings

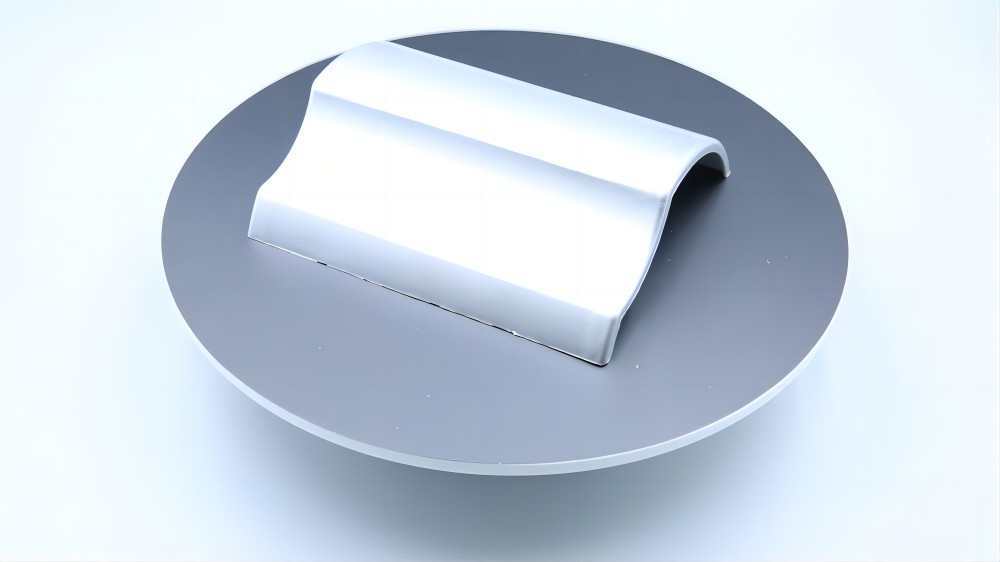

Water-based aluminum paste plays a pivotal role in the paints and coatings industry, contributing to the development of reflective coatings for buildings and automotive applications. In reflective building coatings, the incorporation of water-based aluminum paste offers energy efficiency benefits by reflecting sunlight, reducing heat absorption, and subsequently lowering cooling costs. Additionally, these coatings exhibit excellent UV resistance, ensuring long-lasting protection against the harsh effects of sunlight.

In the automotive sector, water-based aluminum paste is utilized in coatings to provide not only a reflective surface for heat reduction but also to enhance the aesthetic appeal of vehicles. The metallic sheen achieved through the incorporation of aluminum paste adds a premium look to automotive finishes, contributing to the overall visual appeal of the vehicles.

The Secret Weapon of Printing Inks

The versatility of water-based aluminum paste is further evident in the printing industry, where it is employed in various types of inks. In flexographic and gravure inks, the addition of aluminum paste imparts a metallic appearance to packaging materials. This not only enhances the visual appeal of the packaging but also provides printability and adhesion properties, ensuring a high-quality and durable print.

Screen printing inks also benefit from water-based aluminum paste, finding applications in graphics and signage. The reflective nature of the aluminum contributes to vibrant and eye-catching prints, making it a preferred choice for outdoor advertising materials. Moreover, these inks offer durability and weather resistance, ensuring that the prints withstand the elements over time.

Plastic’s Secret Ingredient for Shine and Strength

Water-based aluminum paste finds its way into the world of plastics and polymers, contributing to the development of masterbatch formulations and enhancing the properties of injection-molded products. In masterbatch formulations, the addition of aluminum paste imparts a metallic effect to plastic products, elevating their visual appeal. This is particularly valuable in industries where aesthetics play a crucial role, such as consumer goods and packaging.

In injection molding applications, water-based aluminum paste improves the surface finish of plastic products while providing UV stability. The resulting products not only boast enhanced aesthetics but also exhibit resistance to environmental factors, making them suitable for a wide range of applications, including outdoor and automotive components.

Building Beauty and Brawn in the Construction World

The application of water-based aluminum paste extends to the construction industry, where it is utilized in architectural finishes and concrete additives. In architectural finishes, aluminum paste adds a decorative element to construction materials, contributing to the visual appeal of buildings. Simultaneously, it provides corrosion resistance, ensuring the longevity of these finishes in outdoor applications.

Concrete and mortar additives benefit from the incorporation of water-based aluminum paste, offering enhanced durability to the final products. This is particularly crucial in construction projects where longevity and resistance to environmental factors are paramount. The reflective properties of aluminum paste also contribute to better heat management in construction materials.

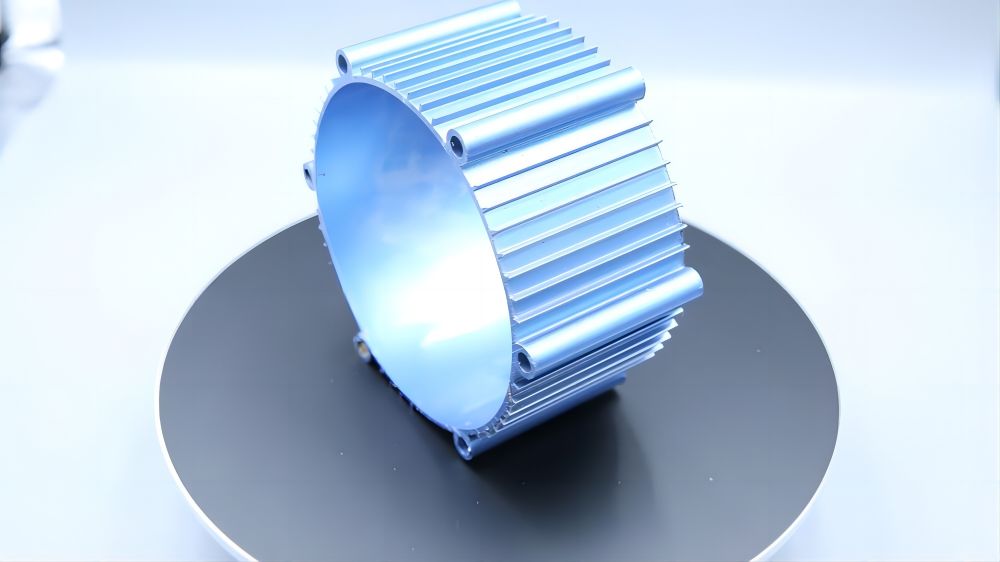

Powering Circuits and Keeping Cool in the Electronics Arena

The unique properties of water-based aluminum paste make it a valuable component in the electronics industry. It is commonly used in conductive inks, where its addition enhances the electrical conductivity of the ink. This is particularly important in printed electronics, where precise and reliable conductivity is essential for the functionality of electronic devices.

Furthermore, water-based aluminum paste is incorporated into thermal management materials used in electronic devices. By dissipating heat efficiently, these materials contribute to the longevity and optimal performance of electronic components. This integration extends to adhesives and encapsulants, where aluminum paste enhances thermal conductivity, providing a crucial function in the ever-evolving field of electronics.

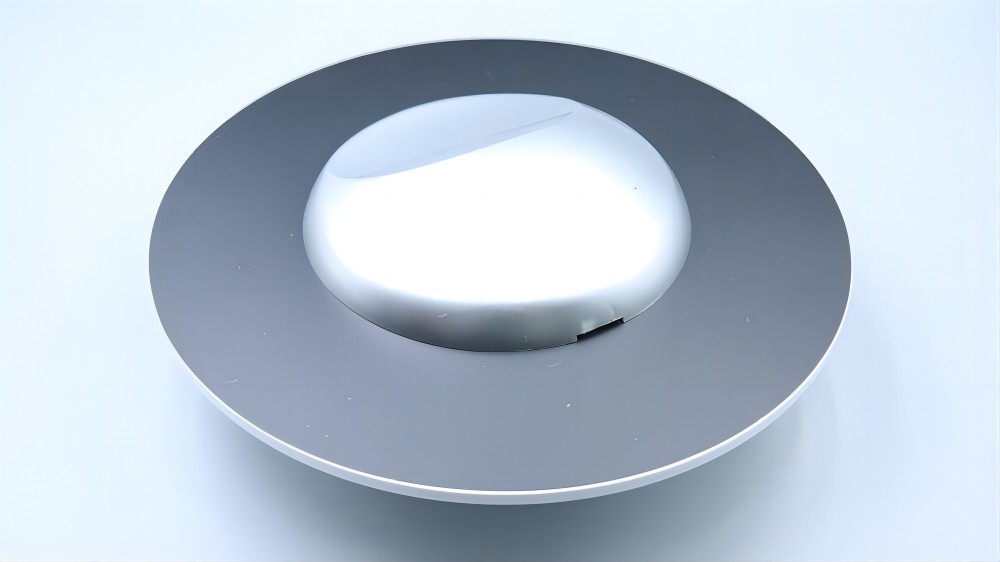

Suncatcher and Efficiency Wizard in the Solar Arena

In the renewable energy sector, water-based aluminum paste finds applications in both photovoltaic systems and concentrated solar power (CSP) technology. In photovoltaic applications, aluminum paste is utilized in reflective layers for solar panels. The reflective surface helps maximize the absorption of sunlight, thereby increasing the energy efficiency of the solar panels.

CSP systems, which utilize mirrors or lenses to concentrate sunlight onto a small area, also benefit from water-based aluminum paste. These solar reflectors enhance the concentration of sunlight, optimizing power generation in these systems. The reflective nature of aluminum paste contributes to the overall efficiency of CSP technology, making it an integral component in the quest for sustainable energy solutions. As the world strives for a cleaner future, water-based aluminum paste holds immense potential for pushing the boundaries of renewable energy generation.

Conclusion

Water-based aluminum paste dances between brilliance and responsibility. Its versatility dazzles in paints, cosmetics, and construction, while its reflective beauty illuminates the path to renewable energy. Yet, concerns echo about its environmental footprint. The challenge, then, is not to dim its shine, but to harness its potential – responsibly. Research whispers of greener formulations, closed-loop manufacturing, and water-conscious processes. Innovation beckons with enhanced performance and uncharted applications. Balancing allure with accountability, we can rewrite the story of this multifaceted wonder. Let the future of water-based aluminum paste gleam with not just brilliance, but also with environmental harmony, painting a canvas of responsible progress for generations to come.