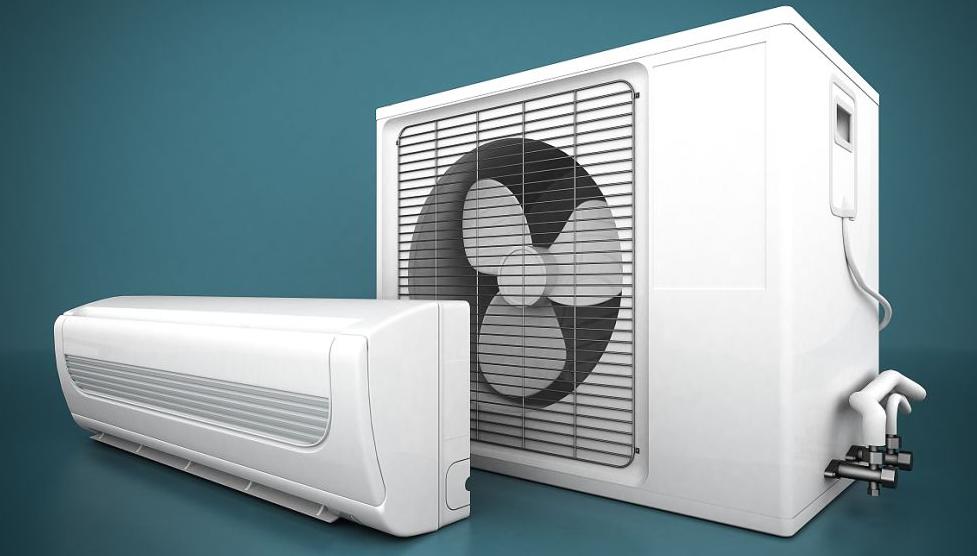

Air conditioning systems are essential for maintaining comfortable indoor environments, especially in regions with extreme temperatures. One of the critical components of these systems is the piping, which transports conditioned air throughout the indoor environments. Among the various materials used for piping, aluminum has gained popularity due to its unique properties. This article will explore the different types of aluminum pipes used in air conditioning systems, their advantages, and why they are a preferred choice.

Why Choose Aluminum Pipes for Air Conditioning

When it comes to air conditioning systems, the choice of piping material is crucial for the overall efficiency, durability, and cost-effectiveness of the system. While copper has traditionally been a popular choice, aluminum is increasingly being considered for its numerous advantages.

- Lightweight: Aluminum is significantly lighter than other commonly used materials like copper and steel. This property makes installation easier and reduces the overall weight of the system, which can be crucial in certain applications.

- Corrosion Resistance: Aluminum has a natural oxide layer that protects it from corrosion. This feature ensures a longer lifespan for the pipes, especially in environments where they are exposed to moisture and other corrosive elements.

- Cost-Effective: Aluminum is generally more affordable than copper, making it a cost-effective option for large installations. The lower material cost does not compromise the performance, making it a popular choice for budget-conscious projects.

- Good Thermal Conductivity: Although not as high as copper, aluminum still offers good thermal conductivity, which is essential for the efficient transfer of heat in air conditioning systems.

- Recyclable: Aluminum is 100% recyclable without loss of its properties, making it an environmentally friendly choice.

Types of Aluminum Pipes for Air Conditioning

Having understood the numerous advantages of using aluminum pipes for air conditioning systems, let’s explore the different types of aluminum pipes available and their specific applications. Each type has unique characteristics that make it suitable for particular aspects of air conditioning.

1. Construction Method: Seamless vs. Welded

Seamless Aluminum Pipes:

Formed from a single, extruded piece of aluminum, creating a continuous, smooth pipe.

Advantages:

Stronger and more pressure resistant due to the absence of a welded seam.

More uniform wall thickness, leading to consistent heat transfer.

Disadvantages:

Typically more expensive than welded pipes due to the manufacturing process.

Limited in length due to the extrusion process.

Welded Aluminum Pipes:

Created by rolling a flat sheet of aluminum into a cylindrical shape and then welding the seam along its length.

Advantages:

More cost-effective than seamless pipes.

Available in longer lengths, offering greater flexibility in installation.

Disadvantages:

The weld joint can be a potential weakness, especially under high pressure.

May have slight variations in wall thickness around the weld, potentially affecting heat transfer.

Choosing Between Seamless and Welded:

- Pressure: Seamless pipes are ideal for high-pressure applications in air conditioning systems, particularly the main supply lines.

- Heat Transfer: When consistent heat transfer is critical, seamless pipes offer a slight advantage.

- Cost: If budget is a major concern, welded pipes can be a viable option for lower-pressure sections of the system.

2. Flexibility: Rigid vs. Flexible

Rigid Aluminum Pipes:

Straight and inflexible pipes offering high strength and durability.

Advantages:

Perfect for main supply lines where straight runs are required.

Offer superior structural support due to their rigidity.

Disadvantages:

Difficult to maneuver around obstacles, requiring careful planning during installation.

Not suitable for tight spaces with numerous turns.

Flexible Aluminum Pipes:

Manufactured from a corrugated aluminum design, allowing for easy bending and maneuvering.

Advantages:

Ideal for tight spaces or situations requiring frequent turns or bends.

Faster installation due to easier handling and adaptability.

Disadvantages:

Lower pressure rating compared to rigid pipes, limiting their use in high-pressure sections.

May require additional support structures to prevent sagging or kinking.

Choosing Between Rigid and Flexible:

- Layout Complexity: For straightforward layouts with minimal turns, rigid pipes are a good choice.

- Space Constraints: Flexible pipes are better suited for tight spaces with numerous turns or obstacles.

- Pressure Requirements: High-pressure applications require rigid pipes for their superior strength.

3. Heat Transfer Efficiency: Finned Aluminum Pipes

Finned Aluminum Pipes:

Regular aluminum pipes with extended fins along the outer surface.

Advantages:

Increased surface area thanks to the fins, leading to significantly improved heat transfer efficiency.

Crucial for components like evaporator and condenser coils where maximizing heat exchange is essential.

Disadvantages:

More expensive compared to regular aluminum pipes due to the additional fin construction.

Requires careful handling to avoid damaging the delicate fins.

Choosing Finned Aluminum Pipes:

- Heat Transfer Needs: Finned pipes are essential for components demanding optimal heat exchange, like evaporator and condenser coils.

- Space Considerations: While finned pipes offer enhanced heat transfer, their size might be a limitation in tight spaces.

Selecting the appropriate type of aluminum pipe for your air conditioning system requires careful consideration of various factors. Understanding the strengths and weaknesses of seamless vs. welded, rigid vs. flexible, and finned pipes helps you make informed decisions. High-pressure areas might benefit from seamless pipes, while flexible options excel in tight spaces. Finned pipes are vital for maximizing heat transfer in specific components. Consulting an HVAC professional can guide you in selecting the most suitable aluminum pipes for your unique air conditioning needs.

CHAL can provide you aluminum pipes for any appliciations, please feel free to contect them for your specific needs.