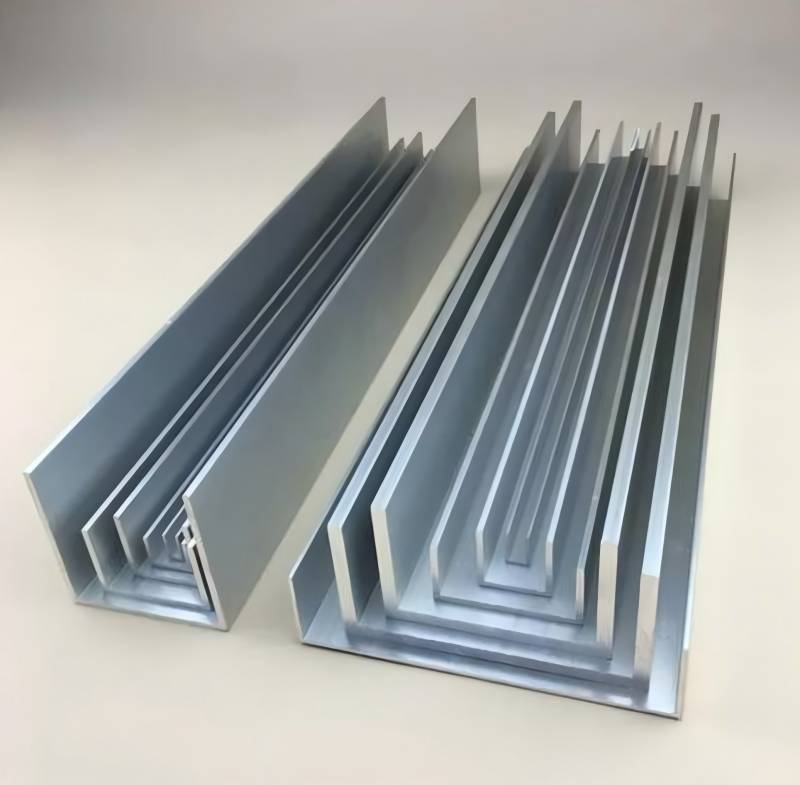

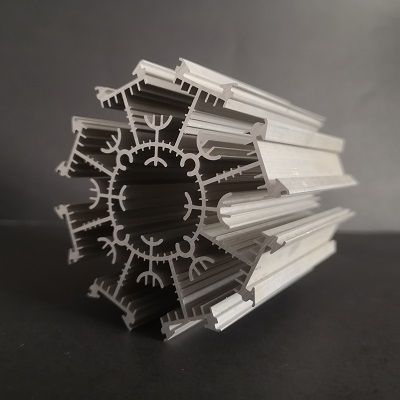

Standard aluminum profiles include architectural, decorative, and industrial aluminum profiles. All kinds of aluminum profiles have a variety of specifications and models. The industry’s most commonly used aluminum profiles are the 6063-T5 series of aluminum profiles. For users, how to choose the appropriate model to use is a critical issue. Aluminum profiles can use the following points to select industrial aluminum profiles.

Strength

Strength is an important indicator to measure the bearing capacity of industrial aluminum profiles. It refers to industrial aluminum profiles’ maximum deformation capacity that breaks or exceeds the allowable limit after loading. In terms of mechanics, tensile strength, compressive strength, and yield strength are the most basic requirements the profile must meet.

Customers can give the necessary industrial aluminum profile models according to their product requirements and corresponding bearing capacity. The amount of deformation, including the maximum allowable bending stress of industrial aluminum profiles, is an essential basis for selecting models. According to the deformation range, it is determined whether the industrial aluminum profiles of this type can meet the bearing capacity required by customers. If not, Choose shapes with large bearing capacity, or increase the bearing capacity by changing the frame structure. You can also follow the designer’s advice and help customers choose aluminum models and aluminum models from the perspective of capacity and performance.

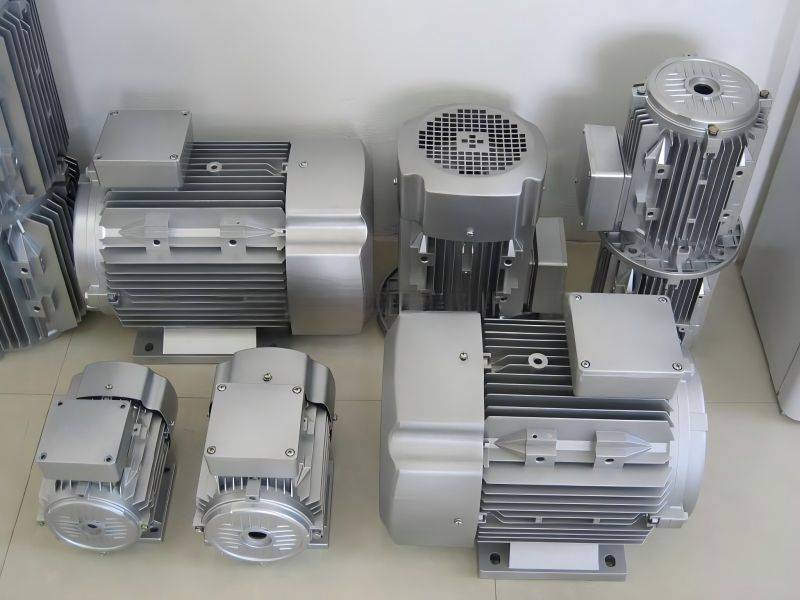

Use Environment

The use environment of the product is also an essential basis for selection. In the production process, industrial aluminum profiles go through the techniques of casting, extrusion, casting, and oxidation coloring. Based on the original oxide film, sandblasting oxidation, anodizing and electrophoretic coating are carried out. In the surface treatment process, the surface coating reaches more than 12μm, the wear resistance, corrosion resistance, high-temperature resistance, and weather resistance are very good, suitable for all kinds of harsh industrial production environments, and customers can choose the required industry according to the production conditions of their factories Aluminum profile model.

Usage Requirements

When choosing the specifications and models of industrial aluminum profiles, users can choose the appropriate aluminum profile models according to the bearing capacity, mechanical properties, and use environment of the equipment frame to be constructed. The parameters are used as a reference, and a proper selection is made according to the use requirements of the equipment frame to be built.

There are various connection methods for industrial aluminum profile accessories, which aluminum profiles can flexibly match according to user needs to ensure the product’s final use performance and aesthetics. You can also consult the aluminum profile manufacturer for usage guidance. The aluminum profile product connectors are diverse and flexible; you can refer to the industrial aluminum profile purchase manual.

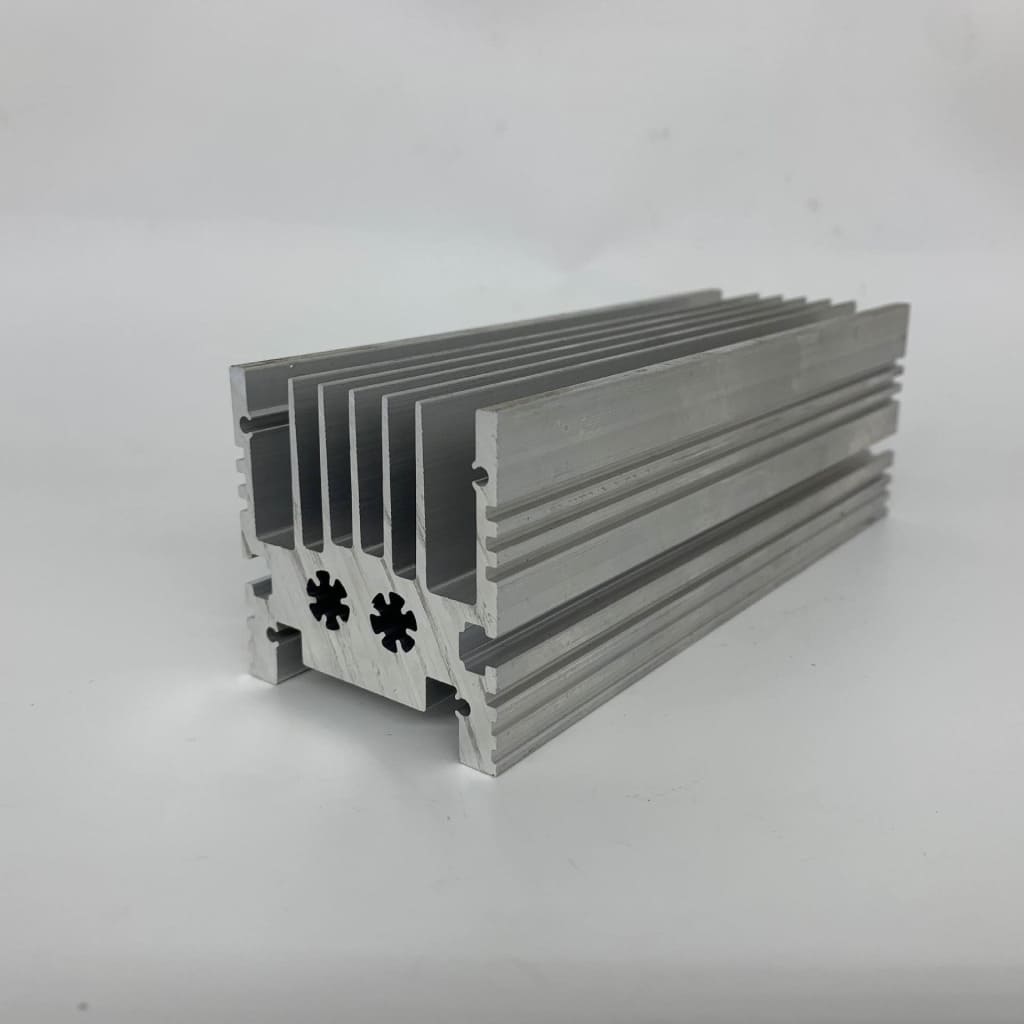

Appearance Requirements

To improve the appearance and performance of industrial aluminum profiles, the anodized film is usually electrolytically colored, electroplated, electrophoretic coating, or electrostatic powder coating, so that the surface is no longer limited to the original silvery white. Still, it can become electrostatic powder coating as Yellow, with electrolytic coloring to golden yellow, bronze, black, brown, and other desired colors. Different processing methods have additional production costs. Suppose there are restrictions on production costs and no requirements for colors. In that case, customers can choose the most specific silver-white color, so the production costs are relatively low, and the color is relatively low. Production workshops with special requirements can select their necessary colors, but the price and investment are relatively high. The better appearance and performance of industrial aluminum profiles can generate more added value for enterprises.