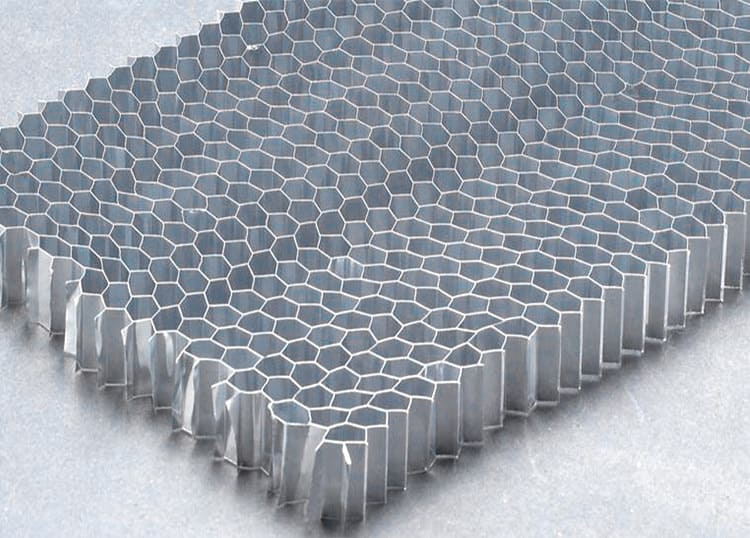

The Aluminium Foil Made Honeycomb Core is a regular honeycomb shape formed by bonding, laminating, stretching, and unfolding through multiple layers of aluminum foil. Due to the special structure of Aluminium Foil Made Honeycomb Core, it can restrict the air circulation in the composite curtain wall panel and greatly limit the propagation of heat and sound waves, so it has good heat insulation, sound insulation, electrical conductivity, heat resistance, corrosion resistance, and absorption. Can, and shock absorption. And thermal insulation performance.

At the same time, its resistance to bending and flexing, compression resistance and light specific gravity are unmatched by other building materials. As the most expensive material in the honeycomb series, Aluminium Foil Made Honeycomb Core has excellent performance. Due to its high strength, high-temperature resistance, and corrosion resistance, Aluminium Foil Made Honeycomb Core is often used in aviation, aerospace, high-speed ships, high-speed rail, and other industries. At the same time, in the construction industry, it is a large-scale curtain wall, and at the same time, it is the material of choice for luxurious interior decoration with high flame-retardant requirements.

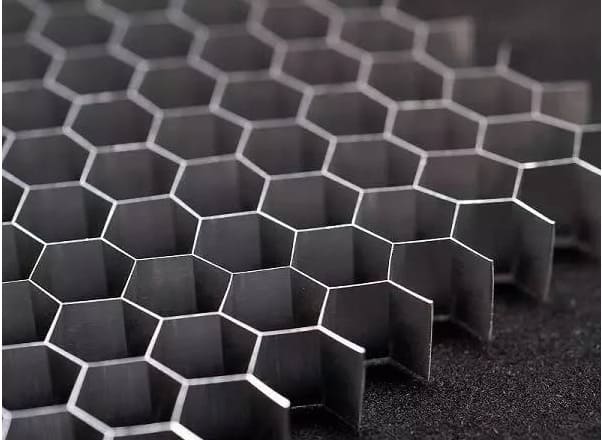

Structure of Aluminium Foil Made Honeycomb Core

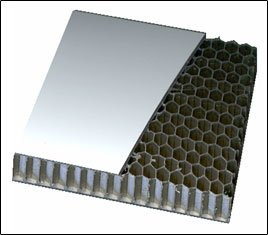

The aluminum honeycomb sandwich structure composite material consists of two high-strength upper and lower skins (also called panels according to the use environment) and a thick and light sandwich layer between them.

Performance Characteristics of Aluminium Foil Made Honeycomb Core

Strength Performance

Aluminum Foil Made Honeycomb Core can separate the skin material, which can increase the bending strength and reduce the quality. The sandwich structure with the same load capacity is several times lighter than the solid layer structure. It can also enhance the overall strength, reduce the cost per unit volume, reduce noise and vibration, and improve heat resistance, fatigue resistance, and fire resistance.

The working principle of the aluminum foil honeycomb core material is to transfer the shear force from the surface layer to the inner layer, so that the two surface layers remain stable under static and dynamic loads, and absorb impact energy to provide anti-destructive performance. Paper honeycomb structure has the advantage of being lightweight, But its performance in terms of bending resistance, shock absorption, and fatigue resistance is extremely low, especially in terms of fire protection. For special environments, such as operating rooms and hospital wards, fire resistance is particularly important.

Sound Insulation Performance

Aluminum honeycomb is a porous discontinuous material, and the solid part has a small cross-sectional area, so the density of the metal honeycomb is very low and the surface area is large.

In the Aluminium Foil Made Honeycomb Core, the volume of the solid part only accounts for 1% to 3%, and the remaining space is a sealed gas. Since the heat and sound insulation performance of gas is better than that of any solid material, the aluminum honeycomb panel has good heat insulation and sound insulation performance. In addition, because the honeycomb has a large specific surface area. When the sound wave touches the metal surface, the sound wave will enter the holes of the honeycomb metal through diffuse reflection, so that the internal vibration of the metal will convert the sound wave into heat energy, which can also play a sound damping effect.

Thermal Conductivity

Since aluminum foil honeycomb core is a product of aluminum foil processed again, it has good electrical conductivity like aluminum foil. The Aluminium Foil Made Honeycomb Core can effectively eliminate the static electricity generated by trains and other vehicles during the driving process, thereby reducing the safety hazards of train driving.

Advantages of Aluminium Foil Made Honeycomb Core

We have learned that the production process of aluminum honeycomb panels is made of internal Aluminium Foil Made Honeycomb Core using high-quality fluorocarbon painted aluminum panels as panels. And it has the advantages of sound absorption and heat insulation, environmental protection, and strong pressure-bearing ability, and the planning of the Aluminium Foil Made Honeycomb Core is indispensable.

Reduce noise

Because the Aluminium Foil Made Honeycomb Core in the aluminum honeycomb panel is divided into many closed cells, the air movement is blocked, the sound wave is blocked, and the sound absorption coefficient is improved (up to 0.9). At the same time, according to the room acoustics planning, different perforation rate planning is carried out, and the sound absorption coefficient of the combined structure can be controlled within a certain range.

Insulation

The material of the aluminum honeycomb core can be seen from the name, which is a metal material made of aluminum alloy. The melting point of aluminum is as high as 660°C, so when a fire occurs, neither the outer aluminum plate nor the central aluminum honeycomb core will ignite.

Environmental Friendly

The aluminum honeycomb core is a pure aluminum product, it does not produce any harmful gas to the human body, is non-radioactive, and can be completely recycled.

Aluminum Foil Made Honeycomb Core can hold more weight

The advantages of aluminum honeycomb panels have a high-strength pressure-bearing ability, which also benefits from the scientific planning of aluminum honeycomb cores. The side panels of the aluminum honeycomb panel are made of high-strength aluminum panels, and the inner layer is a special hexagonal aluminum honeycomb core. As the honeycomb core panel adhered to the sandwich structure, it bears pressure in the tangential direction. These densely-controlled honeycombs are like many small The I-beam can disperse and bear the pressure from the direction of the panel so that the force of the panel is even.

High-quality Aluminium Foil Made Honeycomb Core supplier

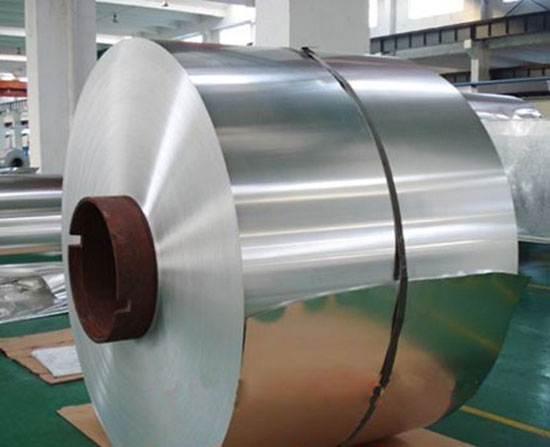

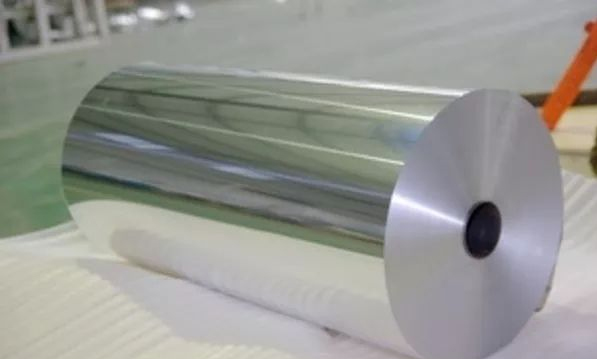

As a high-quality aluminum honeycomb core supplier, I am proud to introduce our CHAL Aluminium Foil Made Honeycomb Core to you. CHAL manufactures aluminum foil with high-quality, optimized for specific applications by the customized thickness and alloy, reasonable price, durable, non-toxic, and grease-proof guaranteed. CHAL will provide honeycomb aluminum foil with various widths and clean oil, high strength, and flatness.