In the process of welding aluminum tubes, there is a silicon-containing flux, which is mainly used for welding aluminum material. The adhesive solution is mainly used to secure the flux on the substrate. Coating solder welding requires the above two materials, but the difference in the process can also result in different results.

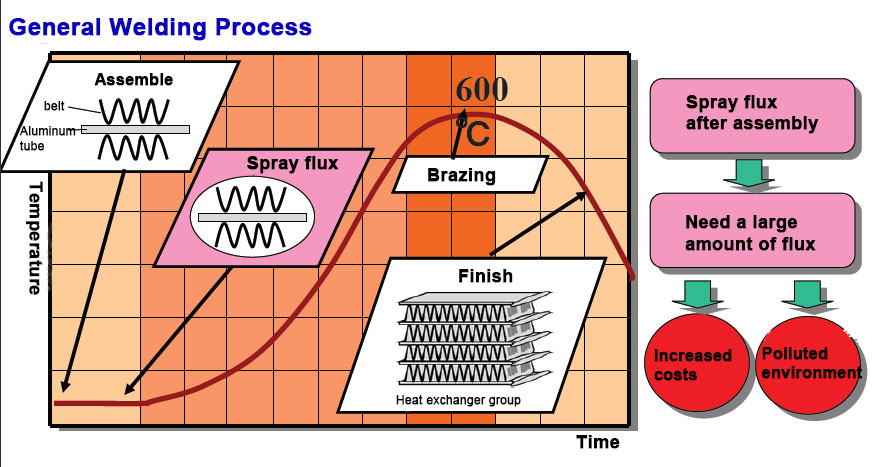

General Welding Process

The conventional flux spray method is generally injecting a large amount of flux while the aluminum tube assembly, which is brazed as the temperature is increased to 600 ° C. As the temperature gradually decreases, the welding process of the flat tube is also completed. In order to understand this process more intuitively, the following is a general welding flow chart:

The disadvantage of this welding process: Since the need to eject a lot of flux after assembly, it will not only increase cost, but also cause environmental pollution.

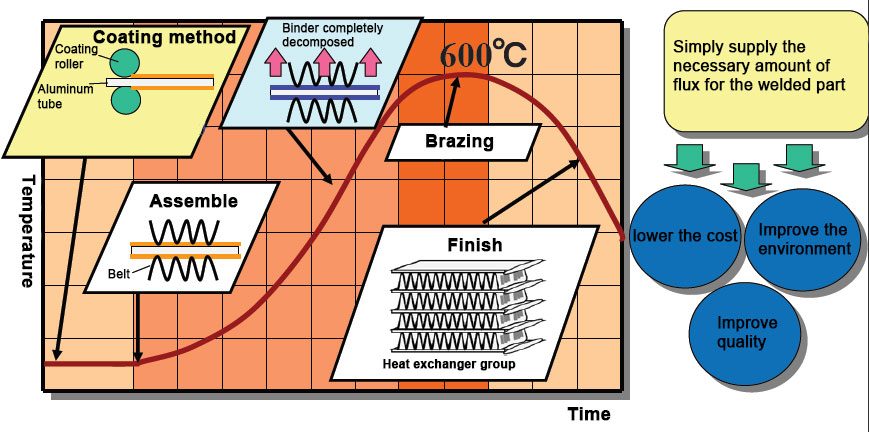

The Coated Solder Welding Process

The coating solder welding is mainly to apply the flux to the aluminum tube prior to assemble the flat tube. As the heating temperature is gradually increased, the binder is completely decomposed, and the soldering is performed when the temperature reaches 600 ° C, and the welding of the flat tube is finally completed. The following is the whole process of coating solder welding:

Comparison of Two Welding Methods

Through the above two welding flow charts, you can know:

①The traditional welding method is not too different from the time used by the coated solder welding method;

②Coated solder welding is less flux;

We can compare advantages from the following aspects:

A. Cost

| Project | spray zinc flat-tube + composite layer fin | coated solder tube + ordinary fins |

| Flat tube price | ordinary spray zinc flat-tube | Ordinary flat-tube + brazing coating |

| Simplify production process | Spray + dry + heating brazing | Heating brazing |

| Flemet tool life (domestic) | About 200 million times | About 1 billion times |

| Sprout | Wetting agent (wet spray or dry spray) | none |

| Cleaning and stove cleaning | need | none |

| Labor costs | Need artificial | none |

B. Work Environment

Typically, the flux for bonded aluminum materials have the following hazards:

①Inhalation harmful

②can cause serious eye damage

③long time and repeated contact can lead to organ damage

④may be harmful to breastfeeding

⑤have long-term toxicity on water organisms

By process comparison, it is known that the flux used by the coating solder welding process is less than the ordinary welding process, so the coating solder is better in improving the working environment.

C. Product Quality and Performance

| Ordinary spray zinc flat tube | Coated solder welding tube | |

| Corrosion resistance (SWAAT ASTM G85) | More than 720 hours (Silicrosa) | Tube is greater than 820hr; (Zinc + Silver Silver) Tube is greater than 1020hr |

| Product qualification rate | silicon permeates in aluminum fins; Hook molten in tubes | No elimination phenomenon |

Summarize:

The advantages of coating solder welding technology are:①low cost; ②can improve the work environment; ③Corrosion resistance time longer.

Ordinary welding technology will still be widely used. With the sustainable development of welding technology, coating solder welding techniques show significant advantages, which can make the coating solder tube better used in the field of heat exchangers. Coated solder aluminum flat tubes also extend the service life of the equipment, if you have more questions about this technology and product, please feel free to contact us.