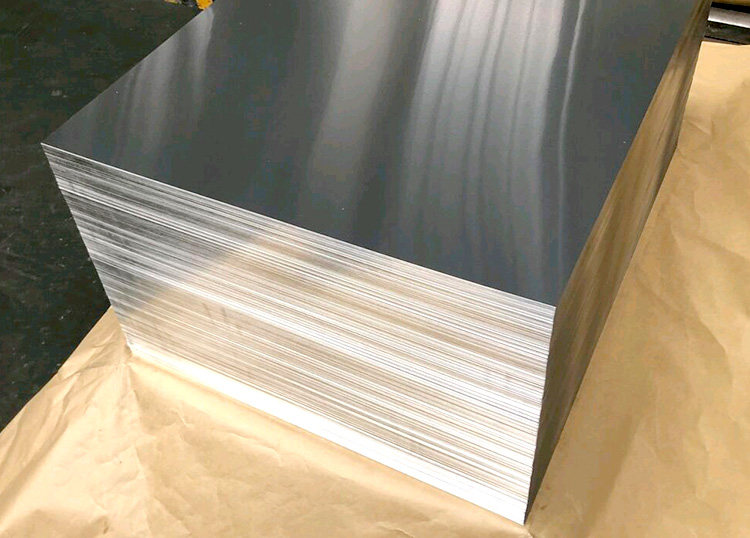

Aluminum mirror sheet is a type of aluminum sheet that has been polished to a highly reflective finish. It is a lightweight, durable, and versatile material that is used in a wide range of applications, including home decor, commercial signage, and industrial products.

What is an Aluminum Mirror Sheet?

Aluminum mirror sheet is made by rolling and polishing aluminum sheet. The rolling process creates a smooth surface, while the polishing process creates a reflective mirror finish. Aluminum mirror sheets can be produced in a variety of thicknesses, widths, and lengths. For customized aluminum mirror sheets please feel free to contact CHAL, the professional aluminum sheet manufacturer in China.

What Types of Aluminum Sheet Can Be Used to Make Aluminum Mirror Sheet?

There are two main types of aluminum sheet that can be used to make aluminum mirror sheet:

- 1000 series aluminum sheet: This type of aluminum sheet is known for its high purity and good formability. It is also relatively soft, making it ideal for polishing to a mirror finish. Common 1000 series alloys used for aluminum mirror sheet include 1050, 1070, and 1085.

- 5000 series aluminum sheet: This type of aluminum sheet is alloyed with magnesium, making it stronger and more durable than 1000 series aluminum sheet. It is also more resistant to corrosion. Common 5000 series alloys used for aluminum mirror sheet include 5052 and 5083.

The specific type of aluminum sheet used to make aluminum mirror sheet will depend on the desired properties of the finished product. For example, if a high-strength mirror sheet is required, then a 5000 series aluminum sheet may be a better choice. If a more economical mirror sheet is required, then a 1000 series aluminum sheet may be a better choice.

In addition to the alloy type, the temper (or hardness) of the aluminum sheet is also important. For aluminum mirror sheet, a soft temper (such as O or H12) is typically used. This allows the aluminum sheet to be easily polished to a mirror finish.

It is important to note that not all aluminum sheet is suitable for use in aluminum mirror sheet applications. The aluminum sheet must be of high quality and have a smooth surface in order to be polished to a mirror finish.

What are the Types of Aluminum Mirror Sheet?

Aluminum mirror sheets can be classified in a number of ways, including the processing methods and the number and color of reflective surface:

By processing methods, including:

- Polished aluminum sheet: This is the most common type of aluminum mirror sheet. It is produced by polishing a rolled aluminum sheet to a mirror finish. Polished aluminum sheet is relatively inexpensive and easy to produce, but it is not as durable as other types of aluminum mirror sheet.

- Anodized aluminum sheet: This type of aluminum mirror sheet is produced by anodizing a rolled aluminum sheet. Anodizing is a process that creates a hard, protective layer on the surface of the aluminum. Anodized aluminum sheet is more durable and scratch-resistant than polished aluminum sheet, but it is also more expensive.

- Mirror finished anodized aluminum sheet: This type of aluminum mirror sheet has the same durability and scratch-resistance as anodized aluminum sheet, but it also has a higher reflective finish.

- Ultra-mirror aluminum sheet: This type of aluminum mirror sheet has the highest reflective finish of any type of aluminum mirror sheet. It is produced by using a special polishing process that removes all imperfections from the surface of the aluminum.

By the number and color of reflective surface, including:

- Standard aluminum mirror sheet: This type of aluminum mirror sheet has a reflective surface on both sides. It is the most common type of aluminum mirror sheet and is available in a variety of thicknesses and finishes.

- One-way aluminum mirror sheet: This type of aluminum mirror sheet has a reflective surface on one side and a transparent surface on the other side. It is often used in security applications, such as two-way mirrors.

- Colored aluminum mirror sheet: This type of aluminum mirror sheet is available in a variety of colors, such as gold, silver, bronze, and black. It is often used for decorative applications, such as furniture and home decor.

What are the Applications of Aluminum Mirror Sheets?

Aluminum mirror sheet has a wide range of applications, including:

- Home decor: Aluminum mirror sheets can be used to create a variety of home decor items, such as mirrors, furniture, and wall art.

- Commercial applications: Aluminum mirror sheets can be used in a variety of commercial applications, such as retail displays, signage, restaurant interiors, and hotel lobbies.

- Industrial applications: Aluminum mirror sheets can be used in a variety of industrial applications, such as solar panels, telescopes, and medical equipment.

How to Choose the Right Aluminum Mirror Sheet for Your Needs?

When choosing an aluminum mirror sheet, there are a few factors to consider:

- Type of aluminum mirror sheet: Reflective aluminum mirror sheet is a good choice for applications where a high degree of reflectivity is required and durability is not a major concern. An anodized aluminum mirror sheet is a good choice for applications where durability and scratch resistance are important.

- Thickness: Aluminum mirror sheet is available in a variety of thicknesses. The appropriate thickness will depend on the application. For example, a thicker aluminum mirror sheet is better suited for demanding applications, such as commercial and industrial applications.

- Size: Aluminum mirror sheet is available in a variety of sizes. The appropriate size will depend on the specific application. For example, large aluminum mirror sheets are often used in commercial and industrial applications.

- Finish: Aluminum mirror sheet is available in a variety of finishes, such as polished, brushed, and anodized. The appropriate finish will depend on the desired aesthetic.

Conclusion

Aluminum mirror sheet is a versatile and durable material that is used in a wide variety of applications. It is a good choice for applications where a lightweight, durable, and corrosion-resistant mirror material is required. It is a more affordable and sustainable alternative to traditional glass mirrors.