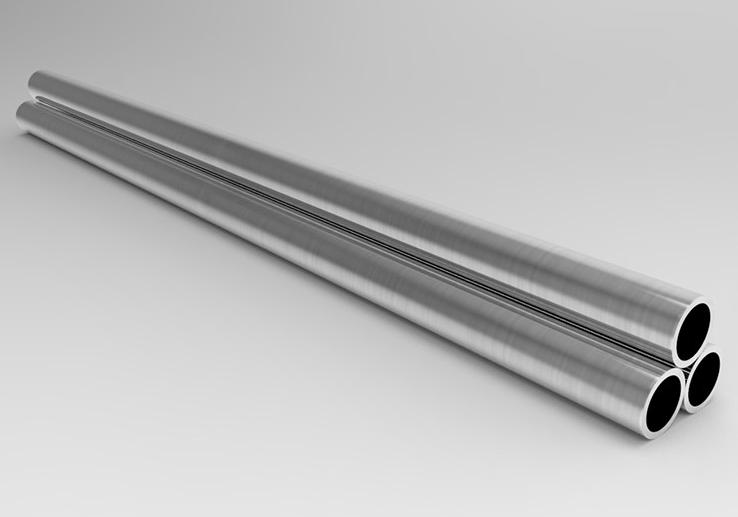

As a kind of non-ferrous metal tube, an aluminum tube is made of pure aluminum or aluminum alloy through extrusion processing to form a hollow metal tubular material along its longitudinal length. It can be strengthened through heat treatment because it is a type of high-strength duralumin. Anodizing and painting methods are often used or the surface is coated with aluminum to improve corrosion resistance, and it can also be used as a mold material. Because of its corrosion resistance and lightweight, it is widely used in various industries such as motor vehicles, ships, aerospace, machinery and equipment, agriculture, and home color TVs.

Aluminum Tube Types

- According to the shape, the aluminum tubing can be divided into square aluminum tubes, round aluminum tubes, pattern aluminum tubes, and special-shaped aluminum tubes.

- According to the extrusion method, the aluminum tubing is divided into seamless aluminum tubes and ordinary extruded tubes.

- According to the precision, the aluminum tubing is divided into ordinary aluminum tubes and fine aluminum tubes. among which fine aluminum tube usually needs to be reprocessed after kneading, such as cold drawing, fine drawing, rolling, etc.;

- According to the thickness of the aluminum tubing, the aluminum tubing is divided into an ordinary aluminum tube and a thin-walled aluminum tube.

Physical Properties of the Aluminum Tube

Aluminum tube or aluminum alloy has low density, but relatively high strength. The aluminum tube is close to or exceeds high-quality steel, which has good plasticity and can be processed into various profiles. The aluminum tube has excellent electrical conductivity, thermal conductivity, and corrosion resistance. Aluminum tubing is widely used in industry, and its usage is second only to steel.

Aluminum alloys can be heat treated to obtain good mechanical properties, physical properties, and corrosion resistance. The hard aluminum alloy belongs to the Al-Cu-Mg system, generally contains a small amount of Mn, and can be strengthened by heat treatment. It is characterized by high hardness, but poor plasticity. Super duralumin belongs to the Al-Cu-Mg-Zn system, which can be strengthened by heat treatment and is the aluminum alloy with the highest strength at room temperature. But the corrosion resistance is poor, and the high temperature softens quickly. Wrought aluminum alloys are mainly Al-Zn-Mg-Si alloys. Although there are many types of elements added, the content is small. Because of their exceptional thermoplasticity and suitability for forging, they are also known as forged aluminum alloys.

4 Features of the Aluminum Tubing

- The aluminum tube has energy-saving advantages. The lower the heat transfer efficiency of the connecting pipeline between the indoor unit and the outdoor unit of the air conditioner, the more energy-saving. In other words, the greater the heat insulation effect, the greater the energy savings.

- The aluminum tube has a long service life. From the perspective of the inner wall of the aluminum tube, since the refrigerant does not contain moisture, the inner wall of the copper-aluminum connecting tube will not corrode.

- The aluminum tube needs welding technology. The thin-walled copper-aluminum tube welding technology that is suitable for industrial production is known as a world-class problem, and it is the key technology for replacing copper with aluminum for air-conditioner connecting tubes.

- The aluminum tube has excellent bending performance and is easy to install and move.

How to Identify the Genuine Aluminum Tube?

Look at the aluminum tube

The Identification of the aluminum tube is carried out by observing and touching the words on the surface of the aluminum tube, the inner and outer layers, etc.

- The words on the surface of genuine aluminum tubes are generally printed with codes, the handwriting is clear, and the general markings such as trademark identification, aluminum tube supplier, address, and even telephone are relatively clear and true. The words on the surface of fake and inferior aluminum tubes are mostly printed by ordinary printing machines, the handwriting is illegible, and the aluminum tube supplier and logo are generally unknown or not marked.

- Genuine aluminum tubes are made of high-quality raw materials, with high process precision. The surface and inner layers are smooth and smooth to the touch, flat, and free of spots. However, fake and inferior aluminum-plastic tubes are relatively poor due to cutting corners.

- The wall thickness of genuine aluminum-plastic tubes and aluminum strips is uniform, and the aluminum tubes are closely combined. The quality and thickness of the tubes and aluminum strips can meet the relevant national standards. But the fake and inferior products have large deviations in wall thickness and thin aluminum sheets, and the gap between the lap joints of the aluminum tubes is large.

Burn aluminum tube

Use an open flame to ignite the aluminum tube. Real aluminum-plastic tubes are made by ultrasonic lap welding or butt welding mainly by hydrogen arc welding. The aluminum sheet is not welded, and its interface is not tight, and the aluminum sheet will fall off after being ignited.

Cut aluminum tube

Use pipe shears to cut the aluminum tube into strips in a spiral shape, and peel off the aluminum pipe layer and PE layer by hand. The real aluminum-plastic tube has a 5-layer composite structure, the aluminum layer, and the PE layer are closely bonded, and the aluminum pipe layer. The PE layer is not easy to separate when peeled off by hand. The fake and inferior products are not tightly bonded to the aluminum layer and the PE layer due to cutting corners. It is easy to peel off.

Measure aluminum tube

Use a small pressure pump to test the pressure resistance of the aluminum tube. The blasting internal pressure of the real aluminum tubing is high, which can generally meet or exceed the requirements of relevant national regulations. But the internal blasting pressure of counterfeit and inferior tubes is generally low or even low, which is difficult to meet the use requirements.