In the machining industry, there are many types of plates with different alloy numbers. For example, the alloy grades of aluminum plates are 5052 and 6061. These two specifications of aluminum plates are similar in chemical composition and production process, but they are used in different fields. Today I will talk to you about the difference between the 5052 aluminum plate and the 6061 aluminum plate.

The performance advantages of 5052 aluminum plate

Aluminum plate 5052 belongs to the 5000 series aluminum alloys. Its main element is magnesium. The magnesium content is between 3-5%, which can also be called aluminum magnesium alloy.

As mentioned above, 5052 aluminum alloy belongs to aluminum-magnesium alloy, so it is widely used in various industries and manufacturing products. Especially in the construction industry, the 5052 aluminum plate is the most promising metal material. It has the advantages of good corrosion resistance, easy welding, and reprocessing.

In addition, the 5052 aluminum plate is the best choice for rust-proof aluminum plates because of its excellent corrosion resistance. 5052 aluminum plate has high strength, especially fatigue resistance. And its plasticity and corrosion resistance are high, so it cannot be strengthened by heat treatment.

5052 aluminum plate has the best plasticity when it is hardened by semi-cold work. When it cools and hardens, it has low plasticity, good corrosion resistance, good weldability, and can be polished for parts with poor machinability.

It is mainly used for low-load parts that require high plasticity and good weldability and work in liquid or gaseous media, such as fuel tanks, gasoline or lubricating oil conduits, or various liquid containers and other deep-drawn parts. Small load parts wire such as “rivets”.

The performance advantages of 6061 aluminum plate

The main alloying elements in 6061 alloy are magnesium and silicon, which have medium strength, good corrosion resistance, weldability, and good oxidation effect. It is widely used in various industrial structural parts that require certain strength and high corrosion resistance.

6061 aluminum alloy belongs to the Al-Mg-Si series alloy with medium strength, good plasticity, and excellent corrosion resistance.

In particular, it does not tend to stress corrosion cracking, has excellent weldability, good corrosion resistance, and cold workability, and is a promising alloy with a wide range of applications.

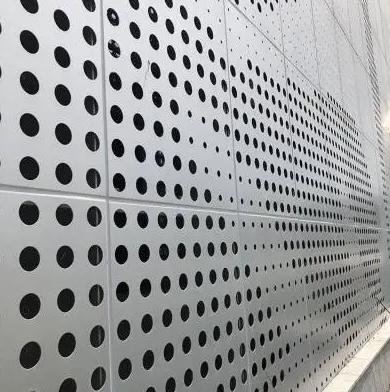

Usually, it can change the appearance color by anodizing method, and can also be painted with enamel, which is suitable for building decoration materials.

It contains a small amount of Cu, so the strength is higher than that of 6063, but the quenching sensitivity is also higher than that of 6063. After extrusion, air quenching cannot be achieved. It needs to be re-solution treated and quenched and aged to obtain higher strength.

6061 & 5052 aluminum plate which is better?

There is no exact answer to the question “who is better between the 5052 aluminum plate and the 6061 aluminum plate”. They are also high-quality aluminum alloy plates with excellent performance. We can only use them in places that are more suitable for them according to their respective advantages.

Their main difference is that

- The two alloy elements are different. The main alloying element of the 5052 aluminum plate is magnesium, which has good forming and processing properties, corrosion resistance, weldability, and moderate strength. The element of the 6061 alloy aluminum plate also contains silicon in addition to magnesium. It has medium strength, good corrosion resistance, weldability, and good oxidation effect. 6061 aluminum plate has excellent processing performance, good corrosion resistance, high toughness, no deformation after processing, easy-to-color film, excellent oxidation effect, and other excellent characteristics. The chemical compositions of the two aluminum grades are as follows.

| aluminum plate | iron | copper | manganese | chromium | Zinc | titanium |

| 5052 aluminum plate | 0.4 | 0.4 | 0.1 | 0.15-0.35 | 0.1 | —- |

| 6061 aluminum plate | 0.7 | 0.15-0.4 | 0.15 | 0.04-0.35 | 0.25 | 0.15 |

- The mechanical properties of the two are different

6061 t6 aluminum performance vs 5052 aluminum performance. The main mechanical properties of aluminum sheets are tensile strength and yield stress. 5052 aluminum plate is Al-Mg system rust-proof aluminum.

5052 has high strength, especially high fatigue strength; similar to alloy 3A21, it has high plasticity and corrosion resistance. It is easy to weld when he contacts welding and hydrogen atom welding, argon arc welding has the tendency of crystal cracking, the alloy has good machinability in cold hardening and semi-cold hardening state, and the machinability in the annealed state is relatively high strength of ASTM B209 alloy 6061 aluminum plate.

| Aluminum plate grade | Tensile Strength(N/mm²) | Elongation (%) | Size Control | Surface | Hardness |

| 5052 H32 Aluminum Plate | 230MPa | 12 | Qualified | Polished Surface Treatment | + 60HB |

| 5052 H34 Aluminum Plate | 260 MPa | 10 | Qualified | Polished Surface Treatment | + 65HB |

| 6061 T651 Aluminum Plate | 290 MPa | 10 | Qualified | black/bright | + 95HB |

Summarize

6061 aluminum plate and 5052 aluminum plate have their own advantages, so you should buy the aluminum plate that is more suitable for you according to your needs.

As a China professional aluminum plate manufacturer, CHAL has been producing different grades of aluminum sheets for many years and selling them all over the world. If you have any questions about buying aluminum sheets, you can find us through “Contact Us”. We will provide you with professional advice.