With the rapid development of the aluminum alloy welding industry at this stage, the types of welding materials are gradually enriched. The following are some common welding materials.

Requirements for the selection of welding wire

When welding aluminum alloys by gas welding, argon tungsten arc welding, etc., it is necessary to add filler wire. Aluminum welding wires are divided into two categories: homogeneous welding wire and heterogeneous welding wire. To obtain a good welded joint, the welding wire suitable for the base metal should be selected as the filler material considering the use requirements of the welded components.

The selection of welding wire should first consider the composition requirements of the weld, but also the mechanical properties, corrosion resistance of the product, rigidity, color, and crack resistance of the structure. Selecting a filler metal with a melting temperature lower than that of the base metal can greatly reduce the tendency for intergranular cracking in the heat-affected zone. For the welded joint strength of non-heat treated alloys, increase in the order of 1000 series, 4000 series, and 5000 series.

5000 series welding wires containing more than 3% magnesium should be avoided in structures with operating temperatures above 65 °C, because these alloys are very sensitive to stress corrosion cracking, and stress corrosion cracking will occur in the above-mentioned temperature and corrosive environment. Using a wire with a higher alloy content than the base metal as the filler metal usually prevents the cracking tendency of the weld metal.

At present, most of the commonly used welding wires for aluminum alloys are standard grades of welding wires that are similar in composition to the base metal. In the absence of standard grades of welding wire, strips can be cut from the base metal instead. In order to refine the seam grains and improve the crack resistance and mechanical properties of the weld, a small amount of Ti, V, Zr, and other alloying elements are usually added to the wire as modifiers.

Problems should be paid attention to when choosing aluminum alloy welding wire

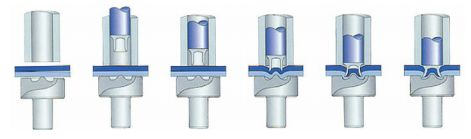

1) Crack susceptibility of welded joints. The direct factor that affects the crack susceptibility is the matching of the base metal and the welding wire. Selecting a weld metal with a melting temperature lower than that of the base metal can reduce the crack susceptibility of the weld metal and heat-affected zone. For example, when welding 6061 alloys with a silicon content of 0.6%, the same alloy is used as the weld, and the crack sensitivity is very high.

However, the ER4043 welding wire with a silicon content of 5% has good crack resistance due to its lower melting temperature than that of the 6061 alloy and higher plasticity during cooling. In addition, the weld metal avoids the combination of magnesium and copper because Al-Mg-Cu has a high crack susceptibility.

2) Mechanical properties of welded joints. Industrial pure aluminum has the lowest strength, 4000 series aluminum alloy is in the middle, and 5000 series aluminum alloy has the highest strength. Although aluminum-silicon welding wire has high crack resistance, the plasticity of silicon-containing welding wire is poor, so for joints that need plastic deformation processing after welding, silicon-containing welding wire should be avoided.

3) Performance of welded joints. The choice of filler metal depends not only on the base metal composition, but also on the geometry of the joint, the corrosion resistance requirements in service, and the appearance of the weldment. For example, welded containers for storing hydrogen peroxide require high-purity aluminum alloys in order to provide good corrosion resistance to the container or to prevent contamination of the container by the stored product. In this case, the filler metal must be at least as pure as the base metal.

Specifications and uses of commonly used aluminum alloy welding rod

Pure aluminum: The specifications of this welding rod are generally 3.2, 4.5, 345 to 355, and are mostly used for welding pure aluminum plates and pure aluminum containers.

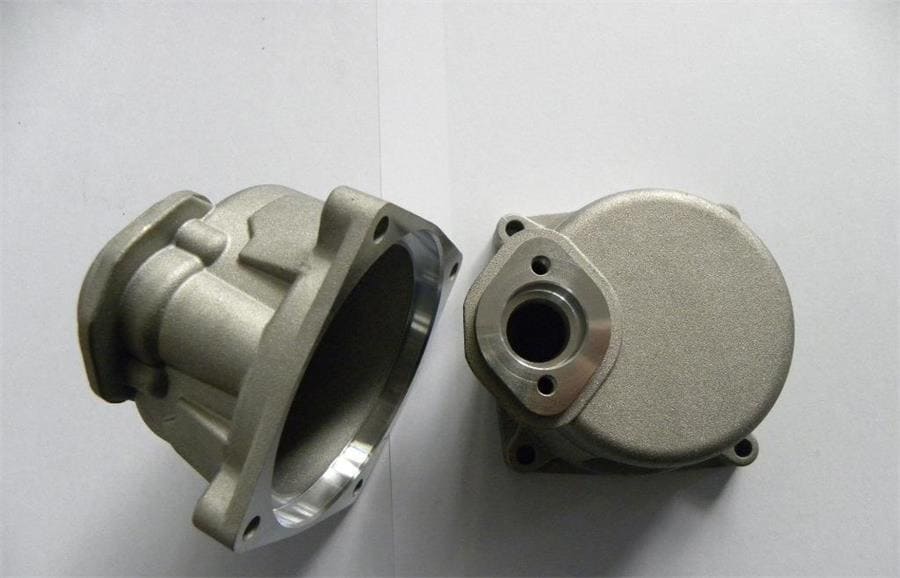

Aluminum-silicon alloy: The specifications of this welding rod are generally 3.2, 4.5, 345-355, and are mostly used for welding aluminum plates, aluminum-silicon castings, general aluminum alloys, forged aluminum, and hard aluminum (except aluminum-magnesium alloys)

Aluminum-manganese alloy: The specifications of this welding rod are generally 3.2, 4.5, 345-355, and are mostly used for welding aluminum-manganese alloys, pure aluminum, and other aluminum alloys.

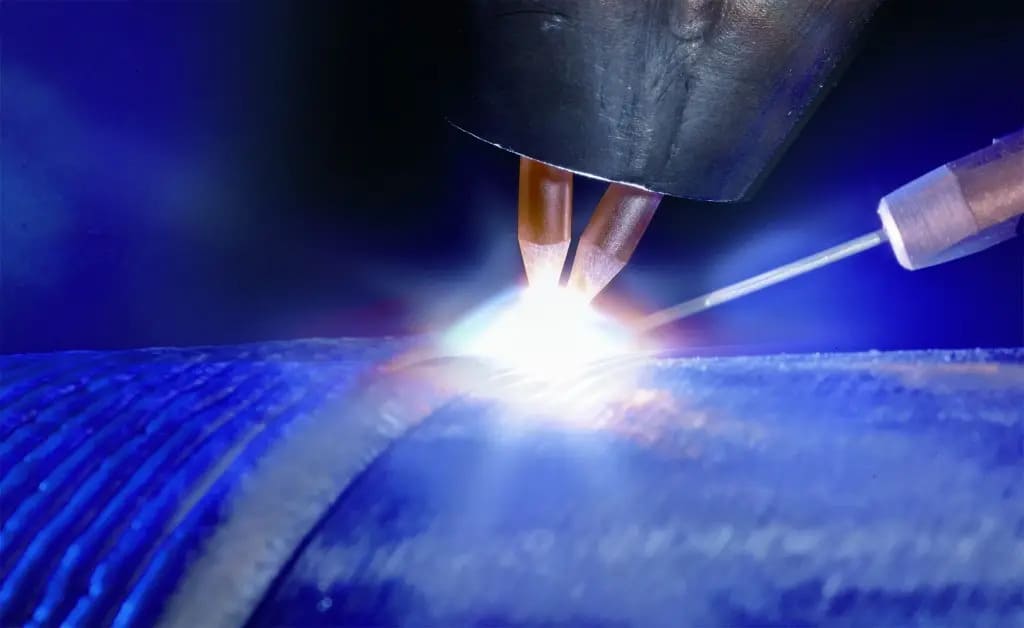

How to choose protective gas?

Inert gases for welding aluminum alloys include argon and helium. The technical requirements of argon are Ar>99.9%, oxygen <0.005%, hydrogen <0.005%, moisture <0.02mg/L, nitrogen <0.015%. Oxygen and nitrogen increase and both deteriorate the cathode atomization. Oxygen > 0.3% will aggravate the burning loss of the tungsten electrode, and if it exceeds 0.1%, the surface of the weld will be dull or black.

In tungsten argon arc welding, pure argon gas is used for AC and high-frequency welding, which is suitable for large-thickness plates; Ar+He or pure Ar is used for DC positive polarity welding.

When melting electrode argon arc welding, when the plate thickness is less than 25mm, pure Ar is used. When the plate thickness is 25 to 50 mm, an Ar+He mixed gas added with 10% to 35% Ar is used. When the plate thickness is 50 to 75 mm, it is advisable to use an Ar+He mixed gas with 10% to 35% or 50% He added. When the plate thickness is greater than 75mm, it is recommended to add 50% to 75% He Ar+He mixed gas.