The electrical product industry constantly seeks materials that can meet the demands of modern devices. Aluminium circles are used extensively due to their excellent formability and ability to meet the stringent requirements of electrical appliance applications. This article delves into the most commonly used aluminum alloy series in the electrical product industry, discussing their specific characteristics and applications.

Common Series Used for Aluminium circles in Electrical Appliances

Aluminum alloys are classified into different series based on their primary alloying elements. Each series offers unique properties, making them suitable for specific applications within the electrical appliance industry. The main series discussed in this article are the 1000, 3000, 5000, 6000, and 8000 series aluminum alloys.

1. 1000 Series Aluminum Alloys

The 1000 series aluminum alloys are also known as the pure aluminum series, with an aluminum content of 99% or higher. This series is renowned for its outstanding conductivity and thermal conductivity, making it highly valuable in the electrical appliance industry.

Composition and Characteristics

- The 1000 series alloys are composed almost entirely of aluminum, with minimal amounts of other elements. This high purity level grants them exceptional conductivity and thermal properties, which are critical for electrical applications.

- These alloys exhibit excellent corrosion resistance due to the natural oxide layer that forms on their surface. This makes them highly durable even in harsh environments.

Applications in the Electrical Appliance Industry

- The 1000 series alloys are widely used in the manufacture of appliance casings and heat sinks. These components benefit from the material’s high conductivity, which aids in efficient heat dissipation and energy transfer.

- Due to their superior corrosion resistance, these alloys help extend the lifespan of electrical products, ensuring they remain operational even in challenging conditions.

For example, aluminium circles from the 1000 series are often used in the construction of electrical enclosures and housings, where they protect sensitive components from environmental factors while also facilitating heat management.

2. 3000 Series Aluminum Alloys

The 3000 series aluminum alloys are primarily composed of aluminum and manganese. This combination gives them a unique balance of properties, making them ideal for specific applications in the electrical appliance industry.

Composition and Characteristics

- The addition of manganese enhances the corrosion resistance of the aluminum, while also improving its strength and formability. These properties are essential for components that need to be both durable and easily shaped.

- The 3000 series alloys are known for their excellent workability, allowing them to be easily molded into complex shapes and designs required for various electrical appliance parts.

Applications in the Electrical Appliance Industry

- In the electrical appliance industry, 3000 series aluminum alloys are commonly used for making appliance casings, covers, and panels. Their enhanced corrosion resistance ensures that the internal components of the appliance are well-protected from environmental damage.

- These alloys are particularly favored for components that need to maintain their structural integrity while being exposed to moisture, chemicals, or other corrosive agents.

A typical use case is in air conditioning units, where aluminium circles made from 3000 series alloys are used in the outer casings, ensuring the internal electronics and mechanical parts are shielded from external elements.

3. 5000 Series Aluminum Alloys

The 5000 series aluminum alloys are based on aluminum and magnesium, which provides a combination of high strength and excellent corrosion resistance. These properties make the 5000 series ideal for applications that require both durability and lightweight materials.

Composition and Characteristics

- The inclusion of magnesium as the primary alloying element significantly increases the strength of the aluminum, without compromising its lightweight nature.

- The 5000 series alloys also offer superior resistance to corrosion, especially in marine and industrial environments. This makes them suitable for components that are exposed to harsh conditions.

Applications in the Electrical Appliance Industry

- The 5000 series aluminum alloys are extensively used in the production of appliance brackets, frames, and other structural components that need to withstand physical stress and environmental exposure.

- These alloys are ideal for applications where strength and stability are crucial, such as in the support structures of heavy-duty electrical equipment.

For instance, aluminium circles from the 5000 series are used in the construction of mounting brackets for large electrical appliances, where they provide the necessary strength to support the weight and operational forces of the equipment.

4. 6000 Series Aluminum Alloys

The 6000 series aluminum alloys are a popular choice in the electrical appliance industry due to their versatility. These alloys are primarily composed of aluminum, magnesium, and silicon, offering a good balance of strength, corrosion resistance, and ease of fabrication.

Composition and Characteristics

- The combination of magnesium and silicon in the 6000 series alloys results in the formation of magnesium silicide, which enhances the material’s strength and allows for heat treatment to further improve its mechanical properties.

- These alloys are known for their excellent weldability and machinability, making them suitable for complex and precise components.

Applications in the Electrical Appliance Industry

- The 6000 series aluminum alloys are commonly used for manufacturing structural parts and heat exchangers in electrical appliances. Their ability to withstand high temperatures and electrical currents makes them ideal for these applications.

- These alloys are also favored for components that require strong weld joints, as they offer excellent welding characteristics without compromising the overall strength of the material.

One example is the use of 6000 series aluminium circles in the production of heat exchangers for industrial and commercial appliances, where they ensure efficient thermal management and contribute to the durability of the product.

5. 8000 Series Aluminum Alloys

The 8000 series aluminum alloys are less common in the electrical appliance industry compared to the other series, but they offer unique benefits in specific applications. These alloys are primarily composed of aluminum and lithium, providing an exceptional combination of strength and lightweight.

Composition and Characteristics

- The addition of lithium to aluminum significantly reduces the density of the alloy while increasing its strength, making the 8000 series one of the strongest and lightest aluminum alloys available.

- Despite their lightweight nature, these alloys maintain excellent structural integrity, making them suitable for applications where weight reduction is critical.

Applications in the Electrical Appliance Industry

- The 8000 series aluminum alloys are particularly useful in portable electronic devices, where reducing the weight of the product is essential for improving portability without sacrificing durability.

- These alloys are also used in specialized components that require both high strength and low weight, such as in aerospace and advanced consumer electronics.

For example, aluminium circles from the 8000 series are used in the manufacturing of lightweight, durable casings for high-end portable electronics, providing users with products that are easy to carry while maintaining robust protection for internal components.

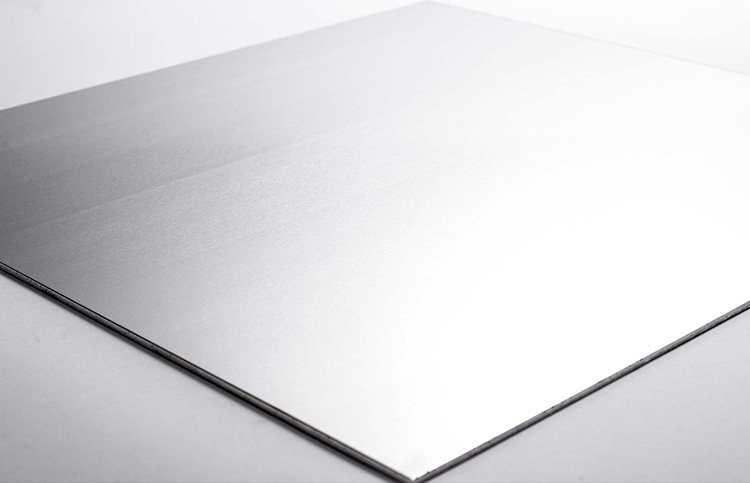

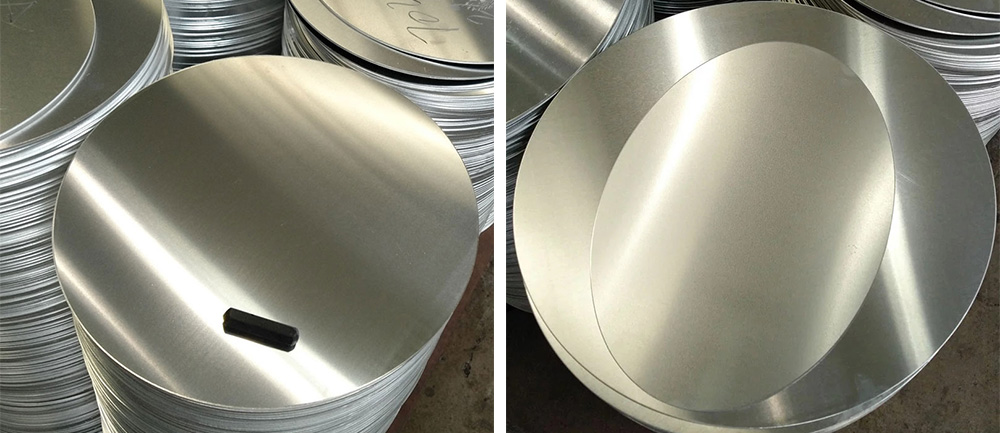

aluminium circles for electrical products use

All the above 5 series of aluminum alloy materials have a wide range of applications in the electrical appliance industry. Choosing the right aluminum alloy material according to different usage environments and performance requirements is the key to ensuring the performance and service life of electrical products.