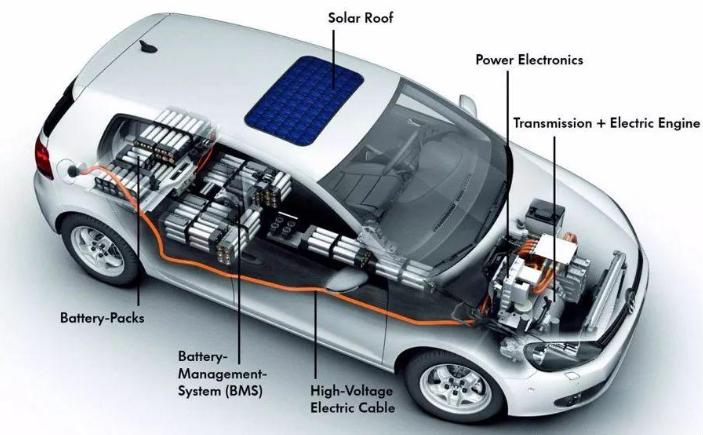

Aluminum is the most used metal material in the world. It is used in various fields such as construction, mechanical equipment, die casting, and bodybuilding. For the processing of aluminum, what we are most concerned about is whether the welding performance of aluminum and aluminum alloy can make it competent for its work. Is the aluminum alloy strong after welding? This article will discuss these issues in depth, please read it patiently.

Welding performance characteristics of aluminum alloy

(1) Strong oxidation ability Aluminum is easily combined with oxygen in the air to form a dense and solid Al2O3 film with a thickness of about 0.1 μm. The melting point of Al2O3 is as high as 2050°C, far exceeding the melting point of aluminum and aluminum alloys (about 660°C), and its volume and mass are large, about 1.4 times that of aluminum. During the welding process, the aluminum oxide film will hinder the good bonding between the metals and easily form slag inclusions. The oxide film also absorbs moisture, which will promote the formation of pores in the weld during welding. Therefore, the oxides on the surface of the weldment must be strictly cleaned before welding, and the protection of the welding area must be strengthened.

(2) Larger thermal conductivity and specific heat capacity The thermal conductivity and specific heat capacity of aluminum and aluminum alloys are about twice that of steel, and a large amount of heat is quickly transferred to the interior of the base metal during the welding process. Therefore, welding aluminum and aluminum alloys consume more heat than steel and preheating and other technological measures are often required before welding.

(3) The thermal crack tendency is large. The linear expansion coefficient is about 2 times that of steel, and the volume shrinkage rate during solidification is about 6.5%. Therefore, when welding some aluminum alloys, thermal cracks often occur due to excessive internal stress. In production, the method of adjusting the composition of welding wire is often used to prevent hot cracks, such as using welding wire HS311.

(4) Easy to form pores The gas that forms pores is hydrogen. The solubility of hydrogen in liquid aluminum is 0.7mL/100g, but at the solidification temperature of 660°C, the solubility of hydrogen suddenly drops to 0.04ml/100g, causing a large amount of hydrogen originally dissolved in liquid aluminum to precipitate and form bubbles. At the same time, the density of aluminum and aluminum alloys is small, and the rising speed of the bubbles in the molten pool is relatively slow. In addition, the thermal conductivity of aluminum is strong, and the molten pool condenses quickly. stomata. The moisture in the arc column atmosphere, the moisture adsorbed by the welding material, and the oxide film on the surface of the base metal are the main sources of hydrogen, so the surface cleaning of the weldment must be strictly done before welding.

(5) Unequal strength of joints The heat-affected zone of aluminum and aluminum alloys is softened due to heat, and the strength is reduced so that the joints and the base metal cannot achieve equal strength. The joint strength of pure aluminum and non-heat treatment strengthened aluminum alloy is about 75% to 100% of the base metal; the joint strength of heat treatment strengthened aluminum alloy is small, only 40% to 50% of the base metal.

(6) Welding through When aluminum and aluminum alloys change from solid to liquid, there is no obvious color change, so it is difficult to judge the temperature of the base metal. During welding, it is often undetectable due to high temperature, which leads to welding through.

What preparatory work should be done before aluminum and aluminum alloy welding?

(1) Cleaning before welding The purpose of cleaning is to remove the oxide film and oil stains on the surface of the weldment, which is an important measure to prevent pores and slag inclusions.

Chemical cleaning With high efficiency and stable quality, it is suitable for cleaning welding wire and weldments with small size and batch production. Chemical cleaning is divided into the dipping method and scrubbing method, cleaning agent, and cleaning process

Mechanical cleaning First uses an organic solvent (acetone, rosin, or gasoline) to wipe the oil on the surface of the weldment, and then use a thin copper wire to brush until the surface reveals a metallic luster, or use a scraper to clean the surface. The cleaned weldment should be welded within 4 hours, otherwise, it should be cleaned again.

(2) Backing plate To ensure penetration and prevent the weldment from being welded through or collapsed, a backing plate can be placed under the joint before welding. The backing plate material can be graphite, stainless steel, or carbon steel, and an arc-shaped groove is opened on the surface to ensure the formation of the reverse weld seam.

(3) Preheating Generally, no preheating is required for thin and small weldments. When welding a weldment with a thickness exceeding 5mm, to achieve the required temperature near the joint, the weldment should be preheated before welding, and the preheating temperature is 100-300°C.

What cleaning work should be done after aluminum and aluminum alloy welding?

The residual flux and welding slag left in the weld and adjacent to the weldment after welding need to be cleaned up in time, otherwise under the action of air and moisture, the residual solvent and welding slag will destroy the anti-corrosion aluminum oxide film and cause severe corrosion. Weldment. Therefore, the residual dirt on the weldment should be strictly removed immediately after welding.