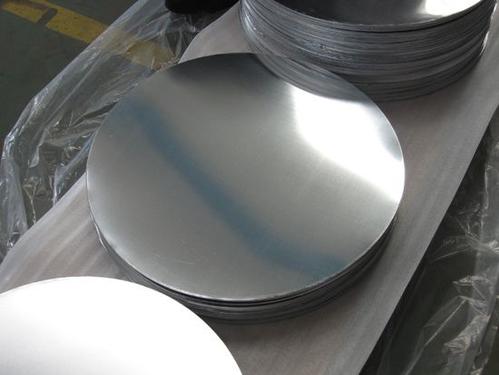

Aluminium circle is also known as aluminum disc, which is a perfect material for making aluminum round metal. Like aluminum plates, aluminum circles are processed aluminum materials made of aluminum alloys. Before buying aluminum circles, you need to know the following knowledge about aluminum circles. They can help you when you buy aluminum circles.

Series and uses of aluminum circle

1 series aluminum disc alloy application

The first series of alloys are also commonly referred to as pure aluminum alloys, and the more representative ones are naturally 1060 alloy aluminum discs.

Because of its relatively high aluminum content, it is relatively soft and suitable for stamping various high-performance products, which is why the first series of aluminum wafer alloys are widely used and have a relatively large market share. For example, rice cookers, kitchen utensils, cooking utensils, etc. all use a series of 1060 alloy aluminum discs as the main material.

3 series aluminum disc alloy application

The three-series alloy aluminum disc is also commonly referred to as a rust-proof alloy. Because the 3003 alloy contains a relatively high manganese element, it has also been called a rust-proof alloy.

It is precisely because it contains manganese that its hardness is harder than that of conventional first-series aluminum discs. Therefore, it is generally used in the field of road signs, especially on both sides of expressways or in underground garages. Road signs processed from 3003 alloy aluminum discs are often easily seen in daily road driving.

5 series aluminum disc alloy application

The five-series alloy aluminum disc is also an alloy series that may be used more in the future. The reason is of course very simple the 5-series aluminum disc has the hardness and the recommended tensile properties at the same time. So it is generally used in the field of containers or other high-end aluminum products.

Generally, the first choice is to use 5-series alloy aluminum circles. We also boldly predict that 5-series aluminum circles may occupy the market before 2025, ranging from 10% to 50%.

6 series aluminum disc alloy application

The 6-series aluminum discs are relatively hard, so the 6-series aluminum plates we see in the market are generally used in the field of molds, but they are not only used in the field of molds. Its use in high-end fields such as containers, ships, aircraft, and automobiles is still relatively large.

Although the 6-series aluminum wafer has a good reputation in the market, the core reason for the poor development of the 6-series aluminum wafer is the high cost, high processing cost, and long production cycle of the 6-series aluminum wafer. restrained. As long as such problems can be effectively solved in the next few years, it is suggested that the market share of 6-series aluminum circles will increase.

Why is the price of aluminum circle higher than that of aluminum plate?

You may be confused when buying aluminum sheets and aluminum plates and find that the price of the aluminum round is higher than that of aluminum plates. Because according to the normal situation, the aluminum material of the aluminum plate should be a little more, and it should be normal that the price of the aluminum plate is high. So why is the price of aluminum wafer higher than that of aluminum plate?

The aluminum disc has good light protection, and after printing and decoration, it can show good color and light effects. It has good insulation and is not easily affected by bacteria and insects. And the shape stability of the aluminum disc is good, and it is not affected by the change in humidity. After simple processing, surface treatment such as printing, color difference, embossing, surface coating, gluing, and varnishing can be performed on the product of aluminum disc, to obtain a more excellent product.

Aluminum discs are usually processed into composite materials with paper and plastic films to be used in the production of products. Therefore, during the processing of aluminum circles, there will be one more continuous stamping process than aluminum plates. Since there is one more process than aluminum plates, more production costs will be added. Therefore, it will affect the quotation of aluminum discs to a certain extent.

Another aspect is that waste will occur in the process of producing aluminum discs. If there are special requirements in the processing of aluminum discs, a lot of waste will be added due to one more process. There is also the use of special models for the production of special-sized aluminum discs, so these factors are the reasons for the high price of aluminum circles at that time.

Why are aluminum circles and aluminum squares brittle?

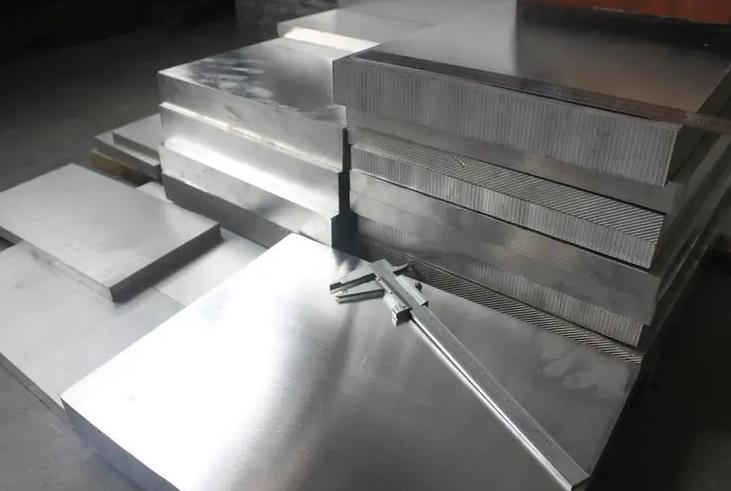

Aluminum circles Aluminum square refers to a rectangular material with a rectangular cross-section and uniform thickness made of pure aluminum or aluminum alloy material by pressure processing (cutting or sawing). But sometimes in the process of using aluminum circles, you will find that the aluminum circles are easy to break. what is the reason?

- The discharge of the die is uneven, the wall thickness of the profile is inconsistent, and the density may be inconsistent. This also constitutes the difference in mechanical function between the two surfaces of the profile.

- The mold section planning of the aluminum wafer is unreasonable, especially since the distribution of the internal meridians and the handling of the interface viewpoints are unreasonable. This can lead to the problem of out-of-specification stress on the aluminum wafer, usually, we need to improve the planning and eliminate the right and sharp angles at the interface of the aluminum wafer.

- The cooling rate and cooling water temperature of the aluminum wafer forming mold do not meet the requirements. The function of cooling water is to cool and shape the stretched macromolecular chain in time so that the aluminum wafer can reach the specified specifications.

- The die pressure of the aluminum wafer is short. If the shrinkage ratio of the die head is too small or the straight section is too short, the produced products will not be fine, and the physical function will be affected.

What should I pay attention to when buying aluminum circle?

1. Look at the machining accuracy of the product

The effect of aluminum discs is different in different fields and may have different requirements for its material function or various aspects, and the requirements for processing technology, mass density, pattern lubricity, etc. Therefore, manufacturers must carry out standard production and manufacturing according to the requirements of users during production, and the multi-dimensional data of materials must meet the standards and ensure that the speed of production is completed within the delivery period.

2. Look at the aluminum content of the product

Aluminum content is a very important factor to measure the quality and function of aluminum circles. Aluminum has the characteristics of lightweight and low density, which is easy to carry, transfer, and process. If the aluminum content is too high, the hardness will not meet the standard, and the aluminum disc may be easily damaged. If the content of aluminum is too low, it will lose the function selection of the aluminum disc, making the quality of the product not up to standard. Therefore, when selecting, be sure to check the raw material content of the product and choose the aluminum wafer that suits your needs.

3. Look at the manufacturer’s service attitude

When dealing with aluminum circles manufacturers, the manufacturer’s service attitude is an effective factor to promote collaboration. The manufacturer’s enthusiasm provides customers with a detailed introduction to product characteristics and the use of aluminum sheets and provides customers with the same enthusiastic service after sales. To deal with the difficulties encountered by customers in the application, a good service team company is a trustworthy company.