Industrial machinery needs to be tough. It operates in demanding environments, frequently under pressure, and needs to perform consistently over long periods. 6061 T651 aluminum is a metal specifically chosen to meet these rigorous standards. This article will explore the properties of 6061 T651 aluminum, making a case for why it is essential for industrial machinery.

Strength Under Pressure: The Properties of 6061 T651 Aluminum

6061 T651 belongs to the 6061 aluminum alloy family, one of the most widely used aluminum in general. The “T651” designation refers to the temper of the aluminum, achieved through a specific heat treatment process. This process strengthens the metal significantly compared to its untreated counterpart, 6061-O.

Here’s a closer look at the properties that make 6061 T651 shine in industrial settings:

- Strength: As mentioned, the heat treatment process significantly enhances the metal’s tensile strength and yield strength. This allows machinery components made from 6061 T651 to handle substantial loads without deformation.

- Machinability: 6061 T651 aluminum can be easily machined, cut, and formed, making it suitable for complex and precise components in industrial machinery. Its ease of machining reduces production time and costs.

- Weldability: Like many aluminum alloys, 6061 T651 can be welded effectively using various techniques, including TIG and MIG welding, without compromising its structural integrity.. This enables the fabrication of large and intricate machinery structures.

- Corrosion Resistance: This alloy exhibits good corrosion resistance, particularly in environments exposed to moisture and other elements. This property enhances the longevity and reliability of machinery components made from 6061 T651 aluminum, making it ideal for industrial environments that may expose machinery to moisture or chemicals.

- Lightweight: Aluminum is inherently lightweight, and the 6061 T651 is no exception. This keeps the overall weight of industrial machinery down, which can improve efficiency and reduce energy consumption.

Built to Perform: Applications in Industrial Machinery

While 6061 T651 aluminum is suitable for a broad range of industrial machinery components, some specific applications take advantage of its unique properties particularly well:

- Machine Frames: The sturdy nature of 6061 T651 makes it ideal for building the supporting structures of various industrial machines. These frames need to be rigid and bear significant loads without bending or warping, and 6061 T651 fulfills this role perfectly. Examples include frames for CNC machines, printing presses, and conveyors.

- High-Precision Components: Thanks to its good machinability, 6061 T651 can be precisely machined to create complex and intricate components needed for industrial machinery. This is especially crucial for parts involved in precise movements or tight tolerances, such as gears, bearings, and valve components.

- Fluid Handling Systems: The corrosion resistance of 6061 T651 makes it a valuable material for pipes and other components used to transport liquids within industrial machinery. This is particularly important when dealing with fluids that could cause corrosion in other metals, such as water-based coolants or mild chemicals.

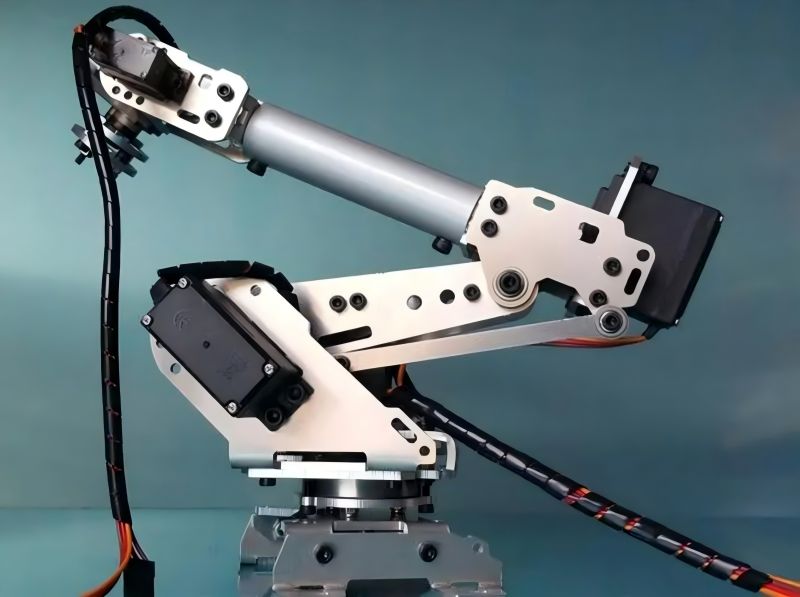

- Robotic Parts: The advantage of being both strong and lightweight makes 6061 T651 a good choice for specific robotic components. In robotics, reducing weight improves speed and efficiency, while maintaining strength is essential for structural integrity and handling payloads. Examples include robot arms and grippers.

- Heavy-Duty Housings: Many industrial machines require protective housings to enclose gears, electrical components, or other sensitive parts. 6061 T651 offers a good balance between strength and workability, making it suitable for creating durable and functional housings that can withstand external impact or pressure.

The Right Tool for the Job: Advantages and Considerations

While 6061 T651 is a versatile and valuable material for industrial machinery, it’s important to consider both its advantages and limitations:

Advantages of 6061 T651 Aluminum in Industrial Machinery:

- Excellent Strength-to-Weight Ratio: This is perhaps the biggest perk. 6061 T651 offers significant strength thanks to the heat treatment process, allowing it to handle substantial loads without succumbing to deformation. At the same time, it remains lightweight compared to other metals, which is crucial for improving efficiency and reducing energy consumption in machinery.

- Good Machinability and Weldability: This aluminum alloy offers excellent workability. It can be easily shaped and formed using standard machining techniques, allowing for the creation of complex components with precise dimensions. Additionally, it can be effectively welded using various methods, facilitating the fabrication of large and intricate machinery structures.

- Corrosion Resistance: 6061 T651 possesses a natural resistance to corrosion, making it ideal for industrial environments that may expose machinery to moisture, chemicals, or other corrosive elements. This promotes a longer lifespan and reduces maintenance needs.

- Relatively Affordable: Compared to some other high-performance metals, 6061 T651 is a cost-effective choice. This makes it a feasible option for a wide range of industrial machinery applications.

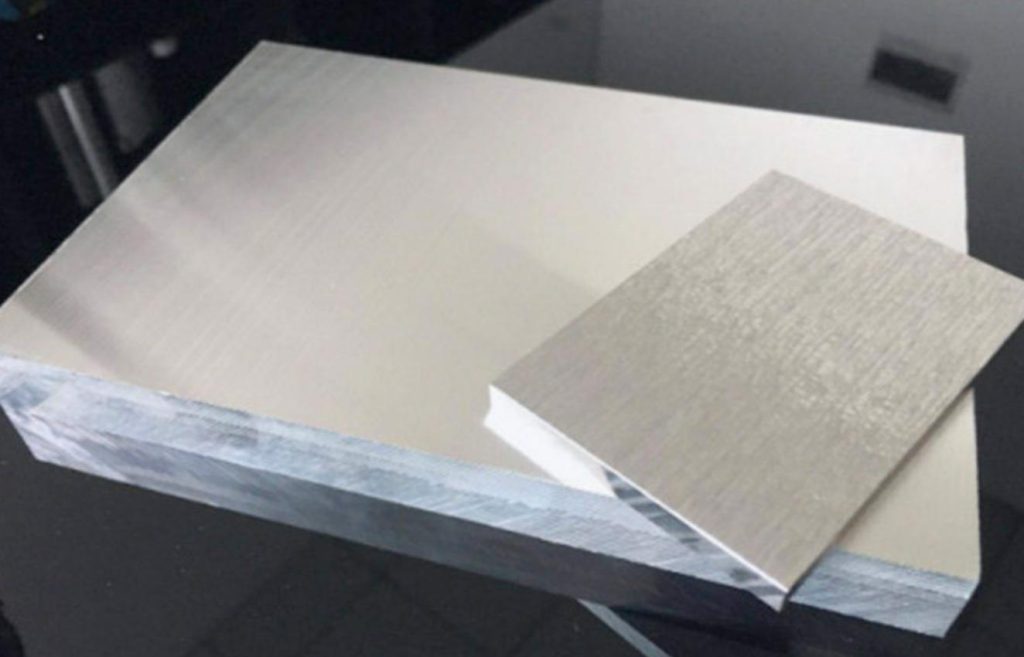

Availability: 6061 T651 aluminum is readily available in various forms, including sheets, plates, bars, and extrusions.

Considerations When Using 6061 T651 Aluminum in Industrial Machinery:

Strength Limitations: While strong, 6061 T651 isn’t the absolute strongest aluminum alloy available. For applications experiencing extremely high stress and loads, other options like 7075 aluminum might be a better fit.

- Cutting and Drilling Techniques: The heat treatment process that enhances strength can also slightly affect machinability. While generally good, certain cutting and drilling operations may require special techniques or tools to ensure clean cuts and prevent premature tool wear.

- Electrical Conductivity: Aluminum itself is a good conductor of electricity. However, 6061 T651 isn’t the best choice for applications requiring optimal electrical conductivity. For such needs, pure copper or specific aluminum alloys formulated for high conductivity might be more suitable.

In conclusion, 6061 T651 aluminum offers a compelling combination of strength, workability, corrosion resistance, and affordability. However, it’s important to understand its limitations in terms of absolute strength and specific machining requirements to ensure it’s the ideal choice for your industrial machinery application.

Get 6061-T651 Aluminum for Your Project

6061 T651 aluminum is a widely available material used by industrial machinery manufacturers around the world. Its combination of strength, workability, and corrosion resistance make it an essential choice for many applications. If you are involved in an industrial machinery project, it’s definitely worth considering the advantages that 6061 T651 aluminum can bring.

To get the best results, work with reputable suppliers who can provide high-quality 6061 T651 aluminum in the form and specifications you need. CHAL is a professional aluminum material supplier for you to consider. By selecting the right material and supplier, you can enhance the efficiency, reliability, and longevity of your industrial machinery.