The packaging industry plays a crucial role in preserving the quality, safety, and longevity of various products, from food items to pharmaceuticals. Among the myriad materials used for packaging, aluminum foil stands out for its versatility, durability, and efficiency. This article delves into the properties, benefits, and applications of 8011 aluminum foil, explaining why it has become a preferred choice for packaging solutions.

Properties of 8011 Aluminum Foil

8011 aluminum foil is an alloy primarily composed of aluminum, with a small addition of manganese significantly enhancing the foil’s overall performance. The typical composition and properties include:

| Property | Description |

| Chemical Composition | Aluminum (Al): 97.0% – 98.9% |

| Iron (Fe): 0.6% – 1.0% | |

| Silicon (Si): 0.5% – 0.9% | |

| Trace elements: Copper (Cu), Manganese (Mn), Magnesium (Mg) | |

| Tensile Strength | 125 – 165 MPa |

| Yield Strength | 110 MPa |

| Elongation | 2% – 5% |

| Density | 2.71 g/cm³ |

| Melting Point | 660.3°C (1220.54°F) |

| Thermal Conductivity | 237 W/m·K |

| Electrical Conductivity | 38% IACS |

Key Properties That Make It Ideal for Packaging:

- High Strength and Durability: 8011 aluminum foil is known for its excellent strength and durability, making it resistant to tearing and puncturing. This property ensures that the packaged products remain well-protected during transportation and storage.

- Flexibility and Formability: Despite its strength, 8011 aluminum foil is highly flexible and can be easily molded into various shapes and sizes, accommodating a wide range of packaging needs.

- Barrier Properties: One of the most significant advantages of 8011 aluminum foil is its ability to act as a barrier against moisture, light, oxygen, and other contaminants. This helps in preserving the freshness and quality of the packaged products.

- Heat Resistance: 8011 aluminum foil can withstand high temperatures, making it suitable for applications that involve heat sealing or cooking.

Benefits of Using 8011 Aluminum Foil in Packaging

Among the various grades of aluminum foil, 8011 aluminum foil stands out due to its unique combination of properties. This alloy, commonly used in packaging applications, offers several benefits that make it an ideal choice for preserving the freshness, flavor, and safety of various products. Here we are the main advantages:

1. Excellent Barrier Properties

One of the primary benefits of 8011 aluminum foil is its outstanding barrier properties. This foil provides an effective barrier against light, oxygen, moisture, and other contaminants, ensuring that the packaged product remains fresh and uncontaminated. These barrier properties are crucial for packaging perishable goods, pharmaceuticals, and other sensitive products, as they prevent spoilage and extend shelf life.

2. High Strength and Durability

8011 aluminum foil is known for its high strength and durability. It is less prone to tearing or puncturing compared to other packaging materials, ensuring that the integrity of the packaging is maintained during handling, transportation, and storage. This durability is particularly important for protecting products from physical damage and maintaining their quality.

3. Lightweight and Flexible

Despite its strength, 8011 aluminum foil is lightweight, which contributes to reducing the overall weight of the packaging. This property is beneficial for transportation and logistics, as it lowers shipping costs and minimizes the carbon footprint. Additionally, the flexibility of aluminum foil allows it to be easily molded and shaped into various forms, making it suitable for a wide range of packaging applications.

4. Non-Toxic and Safe for Food Contact

8011 aluminum foil is non-toxic and safe for direct contact with food products. It does not react with food substances, ensuring that the taste, odor, and nutritional value of the food are preserved. This safety aspect makes it a preferred choice for packaging food items, including snacks, beverages, dairy products, and ready-to-eat meals.

5. Heat Resistance and Conductivity

Aluminum foil has excellent heat resistance and conductivity properties. 8011 aluminum foil can withstand high temperatures, making it suitable for use in cooking, baking, and grilling applications. Its ability to conduct heat efficiently also makes it ideal for use in heat-sealed packaging, where maintaining a hermetic seal is essential for product safety and longevity.

6. Cost-Effectiveness

The production of 8011 aluminum foil is cost-effective, making it an economical choice for packaging. Its durability and barrier properties reduce the need for additional protective layers or materials, further lowering packaging costs. Moreover, the recyclability of aluminum foil contributes to cost savings in terms of waste management and environmental sustainability.

7. Recyclability and Environmental Benefits

Aluminum foil, including the 8011 grade, is highly recyclable. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials, leading to substantial energy savings and a reduction in greenhouse gas emissions. The recyclability of aluminum foil aligns with the growing emphasis on sustainable packaging solutions and environmental responsibility.

8011 aluminum foil offers a myriad of benefits that make it an excellent choice for packaging applications. Its exceptional barrier properties, strength, and durability ensure the protection and preservation of products, while its lightweight and flexible nature contribute to cost savings and logistical efficiency. The non-toxic and heat-resistant characteristics of 8011 aluminum foil further enhance its suitability for food contact and cooking applications. Additionally, its cost-effectiveness and recyclability make it an environmentally friendly packaging option. So, 8011 aluminum foil is as a versatile and reliable material that meets the diverse needs of modern packaging requirements.

Applications of 8011 Aluminum Foil in Packaging

Building on the numerous benefits of 8011 aluminum foil in packaging, it is essential to explore its wide range of applications. From food and beverages to pharmaceuticals and industrial uses, 8011 aluminum foil plays a critical role in ensuring product safety, extending shelf life, and maintaining quality. Here are the specific applications of 8011 aluminum foil in packaging:

1. Food Packaging

8011 aluminum foil is extensively used in the food industry for packaging a variety of products. Its excellent barrier properties protect food from light, oxygen, and moisture, ensuring freshness and extending shelf life. Common applications include:

- Snack Packaging: Chips, nuts, and other snacks are often packaged in aluminum foil pouches to preserve their crunchiness and flavor.

- Dairy Products: Yogurt lids and butter wraps use 8011 aluminum foil to prevent contamination and spoilage.

- Ready-to-Eat Meals: Foil trays and containers are popular for packaging ready-to-eat meals due to their heat resistance and ease of use in ovens or microwaves.

2. Beverage Packaging

In the beverage industry, 8011 aluminum foil is used for packaging a range of drinks, from juices to alcoholic beverages. Its application includes:

- Caps and Closures: Aluminum foil is used to create caps and closures for bottles, providing a secure seal that prevents leaks and contamination.

- Tetra Packs: Foil is an integral part of multi-layered packaging used in Tetra packs, ensuring the longevity and safety of the beverages.

3. Pharmaceutical Packaging

The pharmaceutical industry relies on 8011 aluminum foil for its stringent packaging needs. The foil’ s non-toxic nature and barrier properties make it ideal for:

- Blister Packs: Aluminum foil is used to create blister packs for tablets and capsules, protecting them from moisture, oxygen, and light.

- Strip Packs: Medications are also packaged in strip packs using aluminum foil, which provides a tamper-evident and protective barrier.

4. Cosmetic Packaging

8011 aluminum foil is also used in the cosmetic industry to package various products. Its non-reactive and protective properties are beneficial for:

- Creams and Lotions: Foil seals for jars and tubes ensure product integrity and prevent contamination.

- Sample Sachets: Cosmetic samples are often packaged in foil sachets to maintain product quality and extend shelf life.

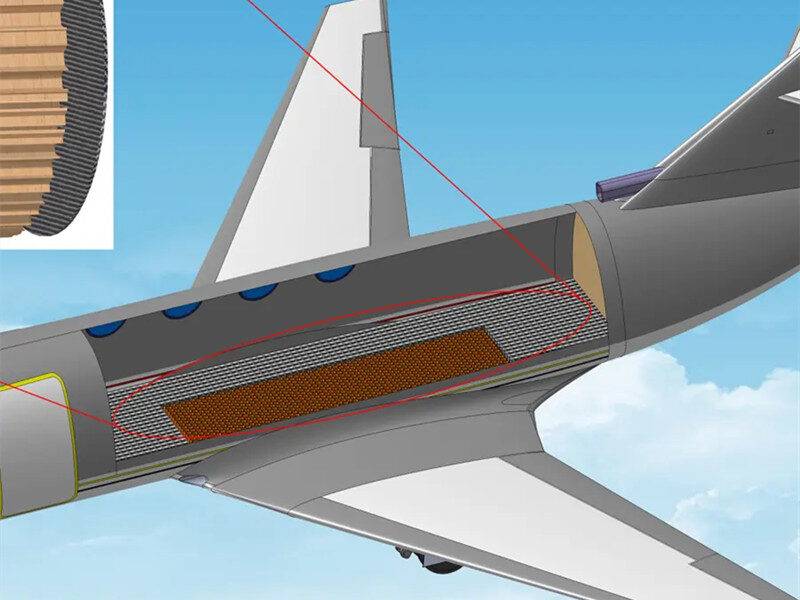

5. Industrial Packaging

In industrial applications, 8011 aluminum foil is used for its strength and durability. It provides reliable packaging solutions for:

- Insulation Materials: Aluminum foil is used to package and protect insulation materials from moisture and physical damage.

- Electronic Components: Foil is used to shield electronic components from electromagnetic interference and static discharge.

6. Household Foil

8011 aluminum foil is commonly used in households for various purposes, such as:

- Food Storage: Foil wraps are used to store leftovers, keeping food fresh.

- Cooking and Baking: Aluminum foil is used in cooking and baking to line trays, wrap food, and cover dishes to retain moisture and heat.

The applications of 8011 aluminum foil in packaging are vast and varied, reflecting its versatility and exceptional properties.

CHAL – Your Aluminum Foil Supplier

Selecting the right supplier for 8011 aluminum foil is crucial to ensuring quality, reliability, and value. CHAL, a leading provider of aluminum products, stands out as an excellent choice for purchasing 8011 aluminum foil. Here’s why CHAL should be your preferred supplier:

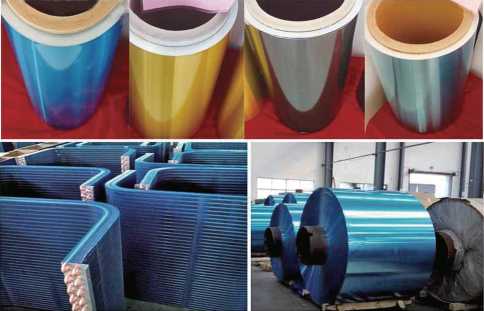

1. High-Quality Products

CHAL is committed to delivering high-quality aluminum foil products. Their 8011 aluminum foil is manufactured to meet stringent quality standards, ensuring superior performance and reliability. The foil produced by CHAL exhibits excellent barrier properties, strength, and durability, making it ideal for various packaging applications.

2. Customized Solutions

CHAL offers customized solutions to meet the unique needs of their clients. Whether you require specific dimensions, thicknesses, or surface treatments, CHAL can tailor their 8011 aluminum foil products to match your exact specifications. This flexibility makes them an ideal partner for businesses with specialized packaging requirements.

3. Competitive Pricing

Despite their commitment to quality, CHAL offers competitive pricing for their 8011 aluminum foil products. By leveraging efficient production processes and economies of scale, CHAL can provide high-quality aluminum foil at cost-effective prices, delivering excellent value for their customers.

4. Reliable Supply Chain

CHAL boasts a robust and reliable supply chain, ensuring timely delivery of aluminum foil products to customers around the globe. Or once you need other aluminum products, their efficient logistics and distribution network minimize lead times and ensure that you receive your orders promptly, helping you maintain smooth operations.

Choosing CHAL for your aluminum foil needs offers numerous advantages not just high-quality products. Their ability to provide customized solutions, competitive pricing, and a reliable supply chain further enhances their appeal as a supplier. With CHAL, you can be confident that you are receiving quality aluminum foil that meets your exact requirements and supports your business success.