Radiant floor heating has become increasingly popular as an efficient and comfortable way to heat homes. This system involves heating a fluid, typically water, and circulating it through tubes embedded in the floor. The heat is then radiated into the room, warming objects and people directly, rather than heating the air. To optimize the performance of radiant floor heating systems, many homeowners and builders turn to aluminum plates. In this article, we will delve into the reasons why aluminum plates are an ideal choice for radiant floor heating.

Understanding Radiant Floor Heating Systems

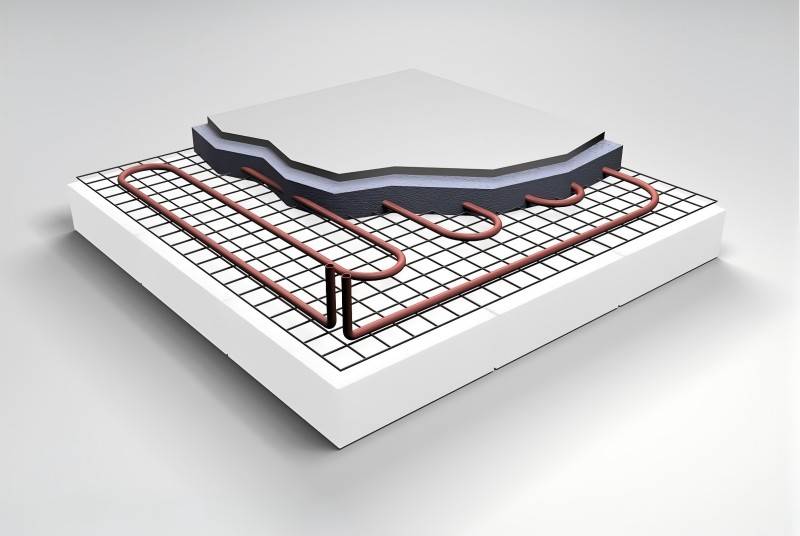

Radiant floor heating systems work by heating the floor directly and transferring warmth into the living space. These systems can be hydronic (water-based) or electric, with the former being more common in residential and commercial applications due to its efficiency in heating larger areas. In a hydronic system, hot water circulates through pipes laid underneath the flooring, warming the floor and, subsequently, the room.

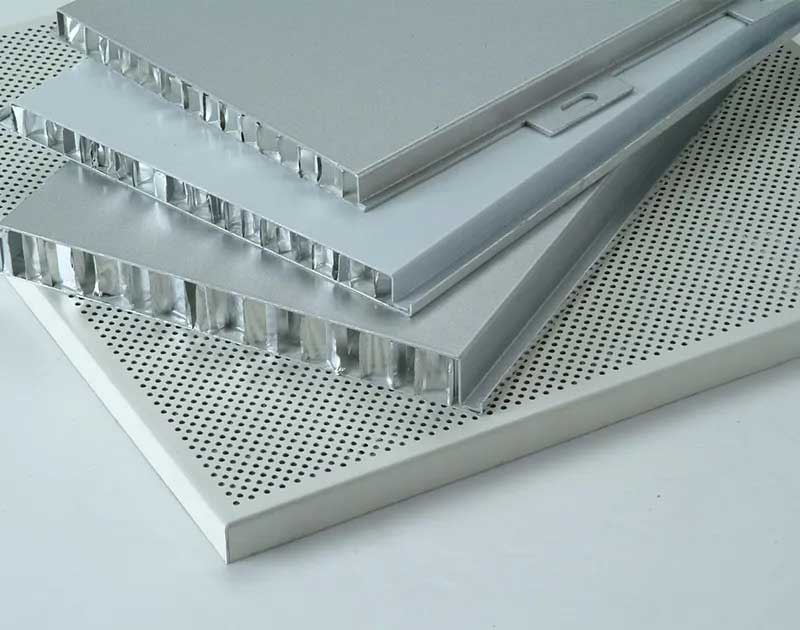

A radiant heating system typically consists of heating pipes, an insulation layer, and conductive plates. The heating pipes, usually filled with heated water, transfer warmth to conductive plates, which then disperse it evenly across the floor. Aluminum plates have emerged as a top choice for this purpose due to their exceptional thermal conductivity properties which enhance and distribute heat effectively.

Radiant floor heating systems offer several advantages over traditional heating methods. By heating the floor, they create a more even temperature distribution throughout the room, reducing cold spots and drafts. This can lead to increased comfort and energy efficiency. Additionally, radiant floor heating can improve indoor air quality by minimizing dust circulation and allergens.

How Aluminum Plates Enhance Radiant Floor Heating Performance

Aluminum plates are highly effective in enhancing radiant floor heating performance, thanks to their exceptional thermal conductivity and unique properties. Here’s a look at why aluminum plates make radiant floor heating systems more efficient and effective:

1. Enhanced Heat Distribution

Aluminum is an excellent conductor of heat, allowing it to evenly distribute warmth across the entire surface area of the floor. When aluminum plates are used in radiant floor heating, they help ensure that heat spreads uniformly, preventing “hot spots” and resulting in a more comfortable environment.

2. Increased Energy Efficiency

By conducting and distributing heat effectively, aluminum plates can reduce the energy required to heat a space. Aluminum’s ability to quickly transfer heat from the heating element to the floor surface means that radiant heating systems can reach desired temperatures faster, reducing energy consumption.

3. Durability and Longevity

Aluminum plates are resistant to corrosion and degradation, which extends the life of the radiant floor heating system. Unlike other metals that may corrode over time due to exposure to moisture or thermal cycling, aluminum maintains its structural integrity and heat transfer efficiency over long periods, making it a reliable choice for radiant heating.

4. Improved Comfort and Responsiveness

Radiant heating systems using aluminum plates provide quick heat-up and cool-down times. This responsiveness allows for precise control over indoor temperatures, contributing to a more comfortable indoor climate. Additionally, the even heat distribution minimizes temperature fluctuations, creating consistent comfort throughout the room.

5. Reduced Material Requirements

Because aluminum is so efficient at conducting heat, radiant floor systems can often use less material while still achieving optimal heating performance. This translates into cost savings both in terms of material and installation while ensuring effective heating with thinner or fewer plates.

6. Eco-Friendly and Recyclable

Aluminum is a sustainable material that can be recycled, making it an eco-friendly option for radiant floor heating systems. Using aluminum plates not only boosts the system’s efficiency but also contributes to sustainable building practices.

Incorporating aluminum plates into radiant floor heating systems significantly enhances their performance, making heating quicker, more energy-efficient, and more comfortable. The use of aluminum allows these systems to operate efficiently, saving energy and ensuring long-term durability. Whether for residential or commercial spaces, aluminum plates play a vital role in modern, high-performance radiant heating systems.

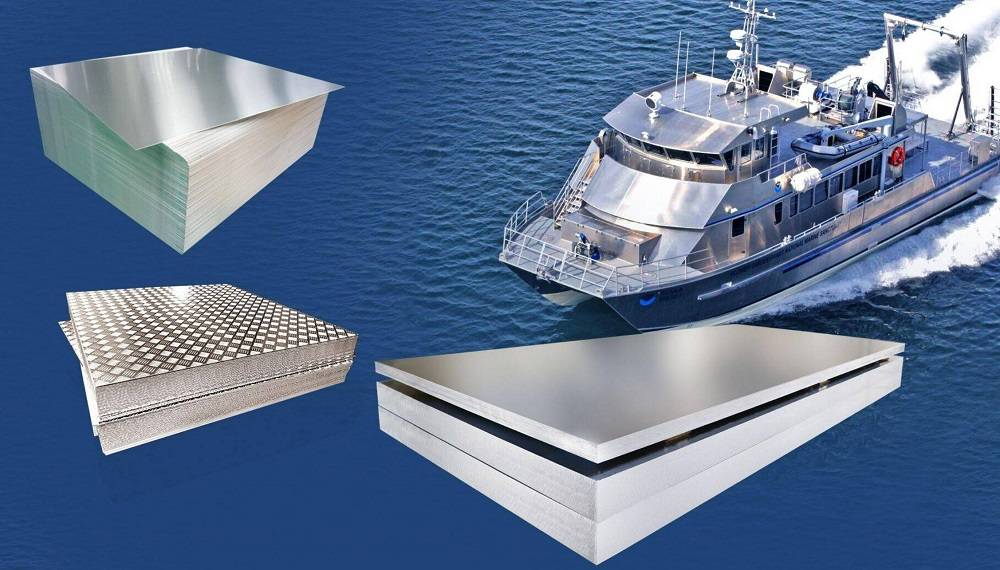

Comparing Aluminum Plates to Other Materials

While aluminum plates are widely used in radiant floor heating, it’s valuable to compare them to other materials, such as copper, steel, and plastic or composite options. Each material has unique properties, but aluminum consistently stands out due to its balance of efficiency, cost, and ease of installation. Here’s how aluminum plates compare to these alternatives in radiant heating applications.

1. Aluminum vs. Copper:

Copper is an excellent thermal conductor, even surpassing aluminum in heat transfer capabilities. This makes copper plates effective at distributing heat, but there are trade-offs. Copper is much heavier than aluminum, which can make installation more challenging and labor-intensive. Copper is also significantly more expensive, leading to higher upfront costs. While copper plates may offer slightly faster heat transfer, the cost difference often outweighs the minor efficiency gain for most residential and commercial applications. Aluminum, therefore, is typically the more economical and practical choice, offering strong heat conductivity at a fraction of the price.

2. Aluminum vs. Steel:

Steel is a durable and robust material often used in various structural applications, but it falls short in thermal conductivity compared to aluminum. Steel heats up more slowly, which can create delays in reaching comfortable temperatures in radiant heating systems. Additionally, steel is heavier than aluminum, making installation more difficult and increasing the structural load on the building. Corrosion resistance is another area where aluminum excels, as steel is more prone to rust and degradation over time, especially in humid environments. Aluminum plates, being both lightweight and corrosion-resistant, are more suitable for radiant floor heating, providing faster and more consistent warmth with less maintenance required.

3. Aluminum vs. Plastic or Composite Materials:

Plastic or composite materials are occasionally used in budget heating systems due to their low cost and lightweight properties. However, they lack the thermal conductivity required for effective heat distribution, leading to uneven and slower heating. Plastic also tends to degrade over time when exposed to the temperature fluctuations common in radiant heating systems, which can reduce the lifespan and efficiency of the system. Aluminum offers a far superior balance, with excellent heat transfer properties, long-lasting durability, and better resistance to temperature changes, making it a more reliable and efficient choice than plastic or composites.

Aluminum plates have proven to be an ideal component for radiant floor heating systems, enhancing both efficiency and comfort through exceptional thermal conductivity, durability, and environmental benefits. Their advantages over materials like steel and plastic make them the top choice for achieving consistent and energy-efficient heating in modern homes and commercial spaces. With the use of aluminum plates, radiant floor heating systems can provide long-lasting warmth, helping to reduce energy costs while offering an eco-friendly option that aligns with sustainability goals. For those seeking effective, reliable heating, aluminum plates are an excellent investment, combining performance with long-term value. Feel free to contact us for any types of aluminum plates.