As modern manufacturing continues to evolve, aluminum stamping parts are increasingly becoming the material of choice for a wide range of industries. These parts are prized for their lightweight and durability and are used in a variety of applications, including automotive, aerospace, and electronics.

Lightweight and Durable: Key Features of Aluminum Stamping Parts

One of the key features of aluminum stamping parts is their lightweight. Aluminum is a relatively low-density metal, which means that it has a high strength-to-weight ratio. This makes it ideal for applications where weight is a critical factor, such as in automotive parts or aircraft components. By using aluminum stamping parts, industries can reduce the overall weight of their products without sacrificing strength or durability.

Another important feature of aluminum stamping parts is their durability. Aluminum is a highly corrosion-resistant metal, which means that it can withstand exposure to harsh environments and corrosive substances. This makes it ideal for applications where parts need to be long-lasting and resistant to wear and tear.

Applications of Aluminum Stamping Parts

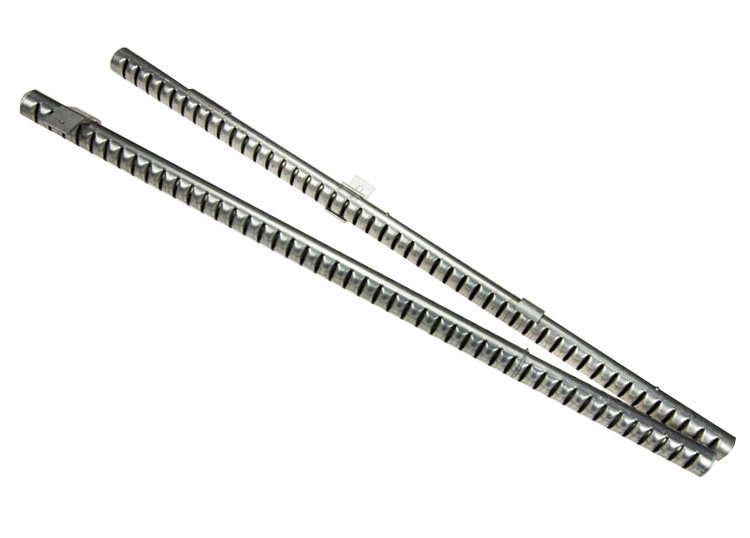

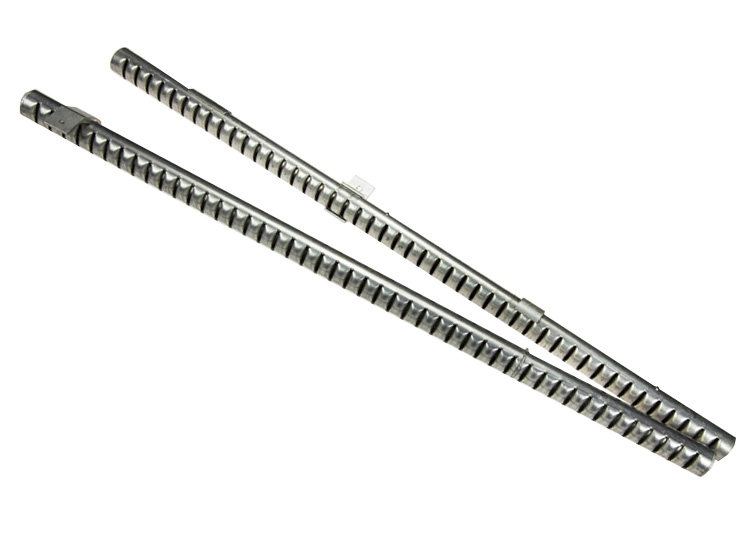

Aluminum stamping parts are made using advanced engineering techniques that ensure precision and consistency. The process involves feeding a sheet of aluminum into a stamping machine, which applies pressure to the sheet to create the desired shape. The resulting parts are then inspected to ensure that they meet the required specifications and quality standards. Thanks to their lightweight and durability, aluminum stamping parts are used in a wide range of applications.

In the automotive industry, they are used to create lightweight parts that improve fuel efficiency and reduce emissions. For example, aluminum stamping parts are used to create hoods, doors, and trunks that are lighter than their steel counterparts, without sacrificing strength or durability.

In the aerospace industry, aluminum stamping parts are used to create aircraft components that are both lightweight and strong. For example, aluminum stamping parts are used to create wings, fuselage panels, and engine components that can withstand the stresses of flight while keeping the overall weight of the aircraft to a minimum.

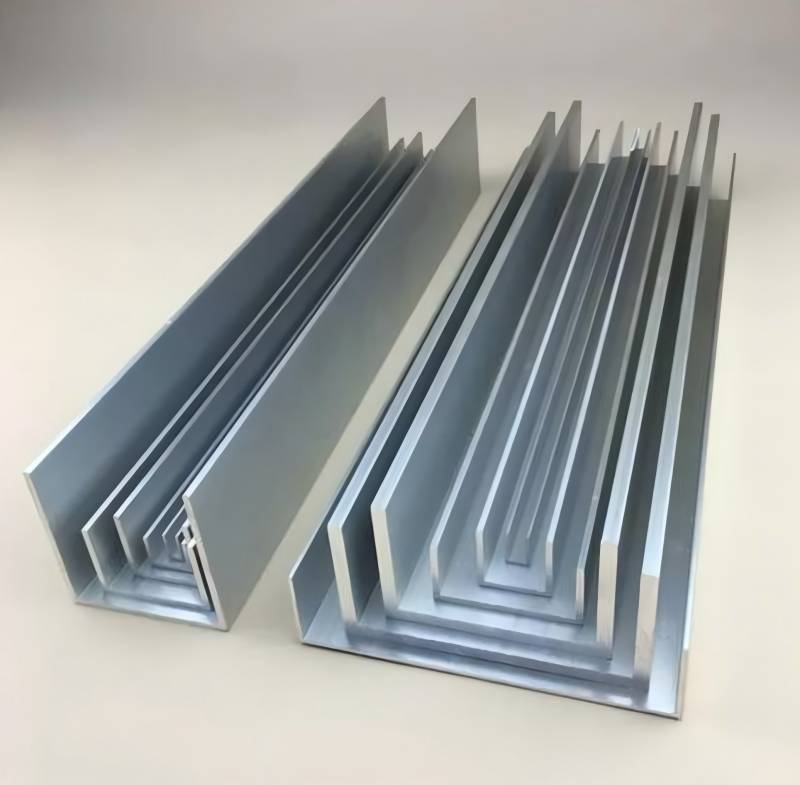

In the electronics industry, aluminum stamping parts are used to create components that are both lightweight and heat-resistant. For example, aluminum stamping parts are used to create heat sinks, which dissipate heat from electronic components and help to prevent overheating and damage.

In addition to their lightweight and durability, aluminum stamping parts offer other benefits as well. They are highly customizable, which means that they can be tailored to meet the specific needs of different industries and applications. They are also highly cost-effective, thanks to their ease of manufacturing and design flexibility.

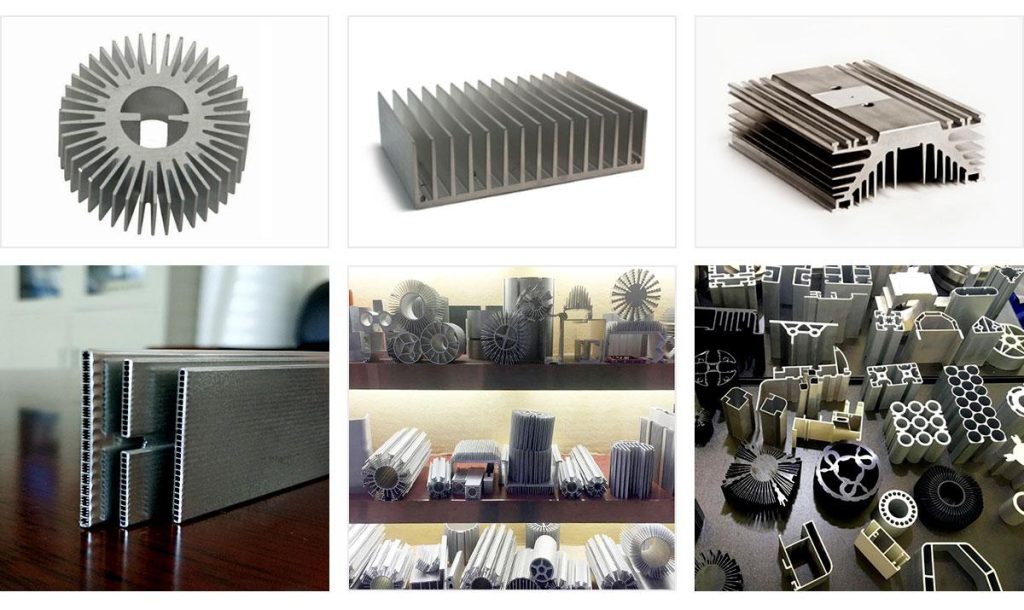

Our Aluminum Stamping Parts

At our company, we specialize in the production of high-quality aluminum stamping parts. Our team of experts has years of experience in the industry, and we use the latest engineering techniques to ensure that our parts meet the highest standards of precision and consistency. Whether you’re looking for automotive parts, aircraft components, or electronics components, we have the expertise and knowledge to help you achieve your manufacturing goals.

In conclusion, aluminum stamping parts are an essential component of modern manufacturing, offering industries a wide range of benefits that include lightweight, durability, corrosion resistance, design flexibility, and cost-effectiveness. As such, they are increasingly becoming the material of choice for a wide range of applications, from automotive to aerospace and electronics. If you’re looking for a trusted and experienced supplier of aluminum stamping parts, contact us today to learn more about how we can help you with your manufacturing needs. Believe that CHAL is your best choice.