At present, the application of aluminum alloy plates in automobiles has been effectively promoted, from Audi’s all-aluminum body, to Chery Jaguar Land Rover’s partial aluminum body, to NIO’s ES8 all-aluminum body. With the full application of aluminium alloys, the technology of stamping production lines is constantly being matured and perfected.

So the question is, why are aluminum stamping parts becoming more and more popular in the market? This article will discuss this topic.

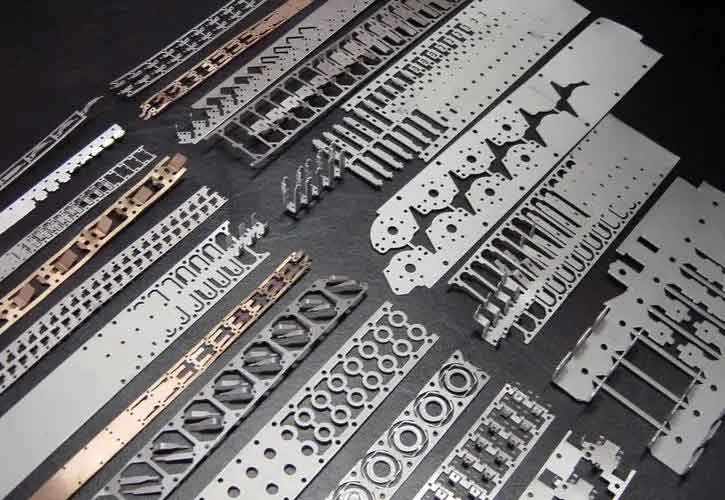

Physical properties of aluminum stamping parts

The popularity of aluminum stamping parts is of course inseparable from its unique physical properties. The plasticity of aluminium alloy stamping parts is very good.

Pure aluminum is very soft, not strong, has good ductility, can be drawn into filaments and rolled into foils, has good machinability, and is widely used in wire and cable manufacturing and the radio industry as well as in the packaging industry.

Adding a small amount of aluminum to some metals can greatly improve their properties. For example, adding a small amount of magnesium and copper to aluminum alloy stamping parts can make tough aluminium alloy stamping parts.

Aluminum stamped parts are lighter in weight than steel. This is good news for industries such as automobile manufacturing, because the concept of “lightweight” is the goal that the manufacturing industry has been pursuing, and it is also the future direction.

Various surface treatments make aluminum stamping parts better

- Fresh aluminum stampings

Fresh aluminum stampings are more or less unable to meet customer requirements in terms of surface quality. To make the workpiece more beautiful and other properties improved, customers usually require surface treatment.

- Sandblasting

The function of sandblasting is to make the surface smoother, make the aluminum parts more beautiful and precise, and can also improve the performance of the workpiece and increase the adhesion between the aluminium alloy stamping parts and the coating.

- Aluminum anodizing treatment

Aluminum anodizing treatment is used to improve the wear resistance and hardness of the surface of aluminium parts, and various surface colors can also be obtained through anodizing.

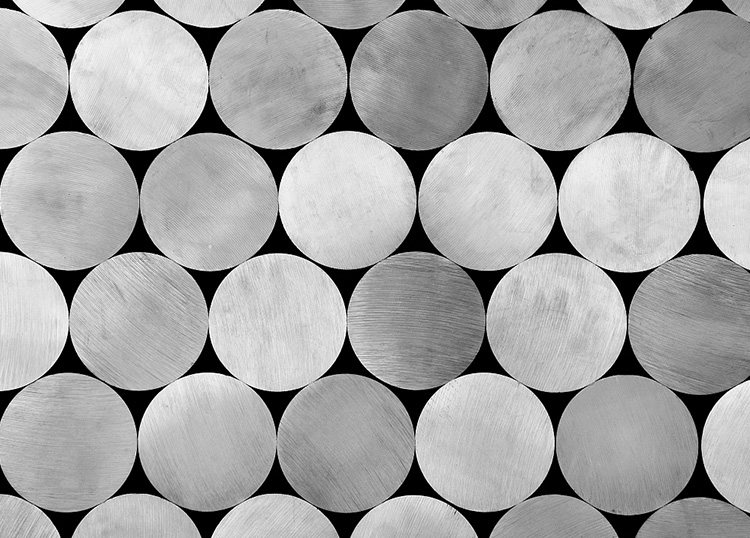

- Wire drawing treatment

Wire drawing is mainly used for decoration, the common types of wire drawing are straight wire drawing, random wire drawing, spiral wire drawing, and thread drawing.

Aluminium Stamped Parts VS Other Materials‘ Stamped Parts

- Mold advantages: The life of a set of aluminum alloy die-casting molds is between 150,000 and 200,000. If it is properly maintained, the life will be longer. However, sometimes a complex part of the stamping process requires several sets of molds to be processed, resulting in increased costs.

- Advantages of mass production: Aluminum alloy die-casting can be mass-produced, with high efficiency and cost saving.

- Safety issues: There will be a certain amount of noise in the process of aluminium alloy die casting, but the noise generated by stainless steel stamping is stronger than that of die casting. With the advancement of mechatronics technology, these problems will be solved as soon as possible.

- Strength advantage: The stamping process is prone to rupture during the forming process, which cannot meet the high-strength processing requirements. However, the material of the aluminum alloy die-casting process will have the characteristics of high strength!

- Aluminum is only 1/3 the weight of steel.

- Aluminum’s strength-to-weight ratio is superior to metals, including stainless steel.

- It has better corrosion resistance than steel. Stamping the aluminium surface creates a corrosion-resistant oxide layer, so it makes aluminum a very low-maintenance material.

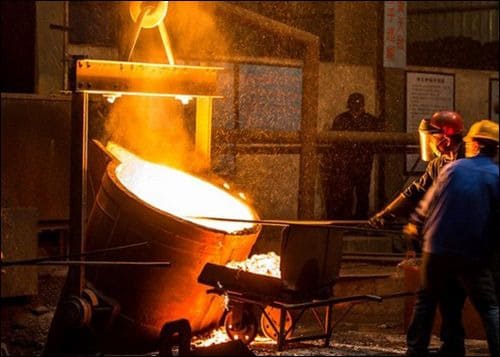

- It has excellent durability in almost any application. It has a lower melting point than steel and can be formed into a variety of complex shapes.

- Aluminum has high electrical and thermal conductivity. And it is non-sparking, non-magnetic and non-flammable.

The reason for the rise of aluminum stamping parts

The reason why aluminum surpasses other metals to become the preferred material for stamping parts, in addition to its characteristics that other metals do not have, the biggest advantage is that aluminium stamping parts have high economic benefits.

In 2022, due to various reasons, the cost of raw materials in the manufacturing industry will increase significantly. Companies want to produce high-quality parts at the lowest possible cost, and aluminum is their material of choice. For the same parts, using aluminum as the material will save more costs.

At the same time, as mentioned above, people are looking for “lightweight” manufacturing methods to reduce the burden on the machine. This is of course also the strength of aluminum. Therefore, aluminium has gradually become the treasure of various manufacturing companies.