Cast aluminum plates are a versatile and essential material in many industries. But with various aluminum alloy options available, selecting the right one for your project can be crucial. Here, we’ll delve into the benefits of choosing 5083 for cast aluminum plate applications.

Understanding Cast Aluminum Plate

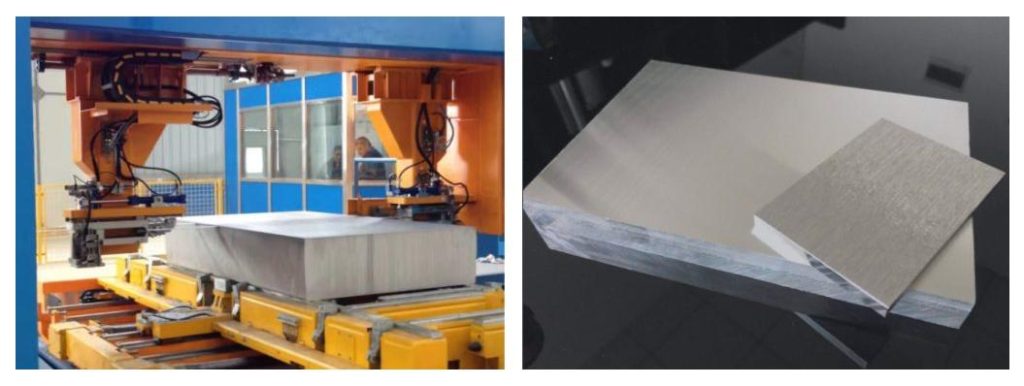

Cast aluminum plate is a type of aluminum product that is created through a casting process, where molten aluminum is poured into a mold to form a specific shape and then allowed to cool and solidify. This method contrasts with other manufacturing techniques like rolling or extruding. Cast aluminum plates are known for their excellent dimensional stability and machinability.

Considerations Before Choosing Cast Aluminum Plate

When choosing a cast aluminum plate, several factors need to be considered to ensure that the material meets the specific requirements of your application. Here are the key considerations:

1. Mechanical Properties

- Strength: Determine the required tensile strength and yield strength based on the mechanical demands of your application.

- Hardness: Consider the hardness of the alloy, especially if the plate will be subject to wear or impact.

- Ductility: Evaluate the ductility if the plate needs to undergo any form of bending or shaping during manufacturing.

2. Thermal Properties

- Thermal Conductivity: High thermal conductivity is essential for applications involving heat dissipation, such as heat sinks or electronic enclosures.

- Thermal Expansion: Consider the coefficient of thermal expansion, especially if the plate will be used in environments with significant temperature fluctuations.

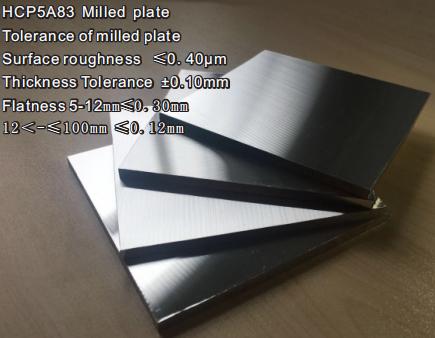

3. Dimensional Stability and Precision

- Flatness and Thickness Tolerances: Ensure the cast plate meets the required flatness and thickness tolerances for your application. Precision in these dimensions is crucial for tooling and high-precision components.

- Residual Stress: Choose plates with low residual stresses to minimize warping and deformation during machining.

4. Machinability

- Ease of Machining: Consider how easily the material can be machined, drilled, or milled. Good machinability reduces production time and tool wear.

- Surface Finish: Evaluate the surface finish that can be achieved after machining, as this may be critical for the final application.

5. Corrosion Resistance

- Environmental Exposure: Consider the operating environment and the potential for corrosion. For marine or highly corrosive environments, alloys with higher corrosion resistance, like 5083, might be preferable.

- Surface Treatments: Determine if additional surface treatments, such as anodizing or coating, are necessary to enhance corrosion resistance.

6. Cost and Availability

- Budget: Align the choice of alloy and plate specifications with your budget constraints. Higher performance alloys typically come at a higher cost.

- Availability: Ensure the chosen alloy and plate dimensions are readily available from suppliers to avoid delays in your project timeline.

By carefully evaluating these factors, you can select the most appropriate cast aluminum plate for your specific application, ensuring optimal performance, durability, and cost-effectiveness.

Why Choose 5083 Alloy for Cast Aluminum Plate?

Choosing the 5083 alloys for cast aluminum plates is often a strategic decision based on the specific properties and advantages that this alloy offers. Here are the key reasons to opt for 5083 alloy:

Great Properties Among Other Alloys

5083 cast aluminum plates have several properties that distinguish them from other cast aluminum alloys, here are the details:

| Property | 5083 Alloy | 6061 Alloy | 7075 Alloy |

| Corrosion Resistance | Excellent resistance to seawater and marine atmospheres, as well as various chemicals. | Moderate corrosion resistance, typically requires protective coatings for marine environments. | Good corrosion resistance, but not as high as 5083 in marine environments. May require surface treatments for enhanced protection. |

| Strength | High tensile and yield strength, suitable for structural applications. | Moderate to high strength, suitable for a wide range of applications. | Very high strength, especially in T6 temper, ideal for aerospace and high-performance applications. |

| Weldability | Excellent weldability with various methods, maintains strength post-welding. | Good weldability, but may be prone to hot cracking in certain conditions. | Fair to good weldability, may require preheating and post-weld heat treatment for optimal results. |

| Machinability | Relatively easy to machine despite its high strength, suitable for complex shapes. | Easy to machine and form, widely used for a variety of machining applications. | Challenging to machine due to its high strength, requires specialized tooling and techniques. |

| Thermal Conductivity | Good thermal conductivity, facilitating effective heat dissipation. | Good thermal conductivity, suitable for heat sink applications. | Lower thermal conductivity compared to 5083 and 6061, but still adequate for many applications. |

| Electrical Conductivity | Adequate electrical conductivity for many electrical applications. | Good electrical conductivity, suitable for electrical components. | Good electrical conductivity, particularly in the annealed condition. |

| Dimensional Stability | Shows low residual stress, minimizing warping and distortion during machining. | Maintains dimensional stability under mechanical and thermal stress. | Good dimensional stability, but may experience more distortion during machining compared to 5083. |

Choosing 5083 alloy for cast aluminum plates provides a combination of high strength, excellent corrosion resistance, good weldability, and reliable machinability. These properties make it particularly suitable for demanding environments, especially in marine, transport, and industrial applications. The balance of these characteristics ensures that components made from 5083 alloy are durable, reliable, and capable of maintaining their performance over time.

Various of Applications

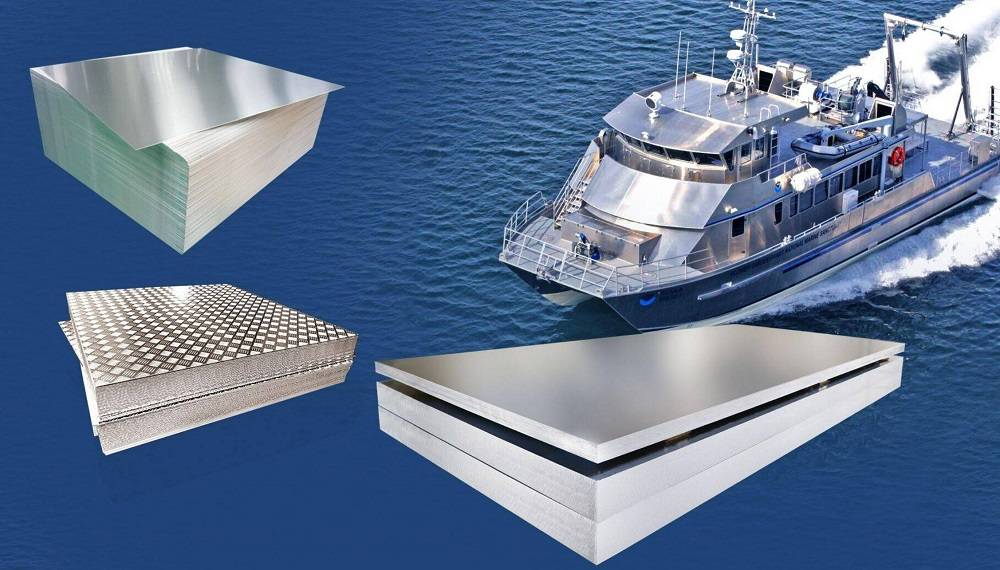

5083 cast aluminum plates find applications in various industries where their unique combination of properties makes them well-suited for specific uses. Here are some specific applications of 5083 cast aluminum plates:

| Applications | Description | Examples |

| Boat Building | Used in the construction of hulls, decks, and other components due to its exceptional corrosion resistance to seawater. | Recreational boats, yachts, naval vessels |

| Marine Structures | Suitable for offshore oil rigs, platforms, and other marine structures where corrosion resistance and structural integrity are critical. | Offshore oil platforms, marine terminals, seawalls |

| Truck Trailers | Utilized for truck trailer bodies, providing durability, corrosion resistance, and lightweight construction. | Freight trailers, flatbed trailers, refrigerated trailers |

| Pressure Vessels | Used in the fabrication of pressure vessels for industrial processes requiring corrosion-resistant materials. | Chemical processing vessels, storage tanks, boiler components |

| Cryogenic Applications | Suitable for cryogenic applications due to its low-temperature toughness and resistance to embrittlement. | LNG storage tanks, cryogenic containers, liquid nitrogen vessels |

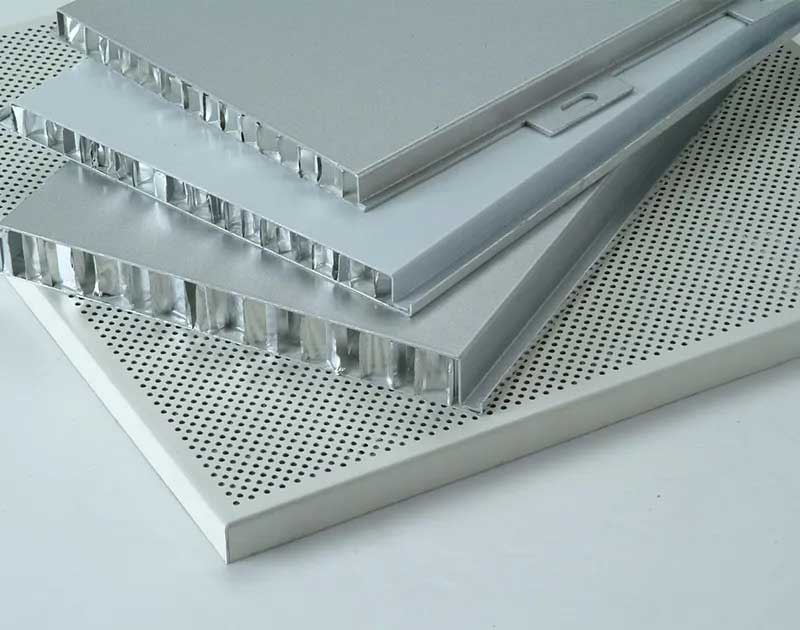

| Heat Exchangers | Utilized for manufacturing heat exchangers and radiators in automotive and heavy equipment applications due to its excellent thermal conductivity. | Automotive radiators, HVAC systems, industrial heat exchangers |

| Tooling and Fixtures | Used for manufacturing jigs, fixtures, and tooling due to its stability, machinability, and dimensional accuracy. | Machining fixtures, inspection jigs, assembly fixtures |

| Machine Components | Employed in the production of machine parts requiring high strength, corrosion resistance, and precision. | CNC machine components, hydraulic system parts, robotic arms |

| Aerospace Components | Used for manufacturing aircraft components such as wing skins, fuselage panels, and structural members due to its high strength-to-weight ratio. | Aircraft wings, fuselage frames, landing gear components |

| Vehicle Armor | Employed in the production of armored vehicles and military equipment due to its high strength and ballistic properties. | Military vehicles, armored personnel carriers, bulletproof vests |

5083 cast aluminum plates are versatile materials with a wide range of applications across industries. Whether it’s building ships, manufacturing aircraft components, or fabricating pressure vessels, 5083 cast aluminum plates offer reliability, durability, and performance in various challenging conditions.