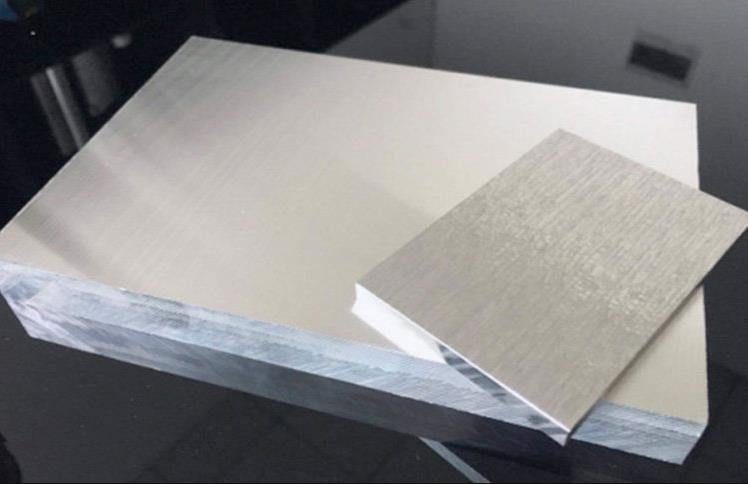

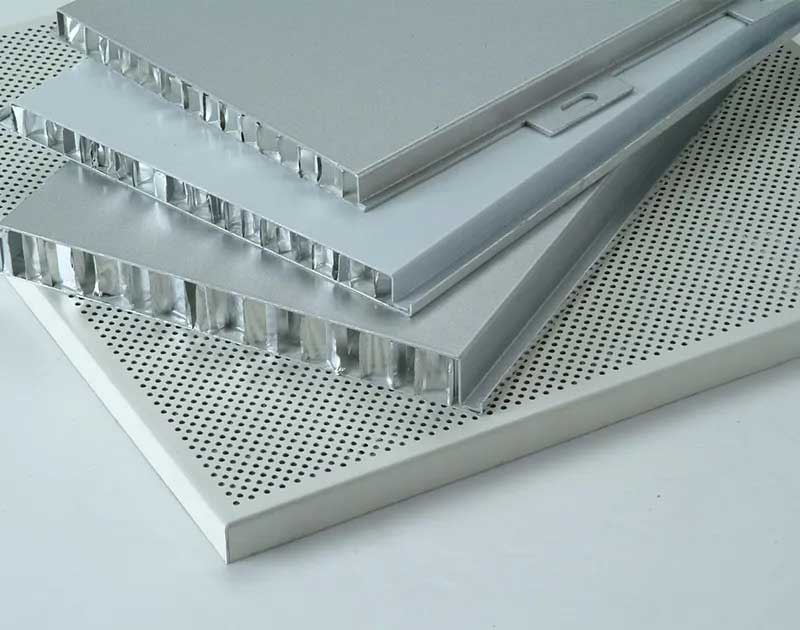

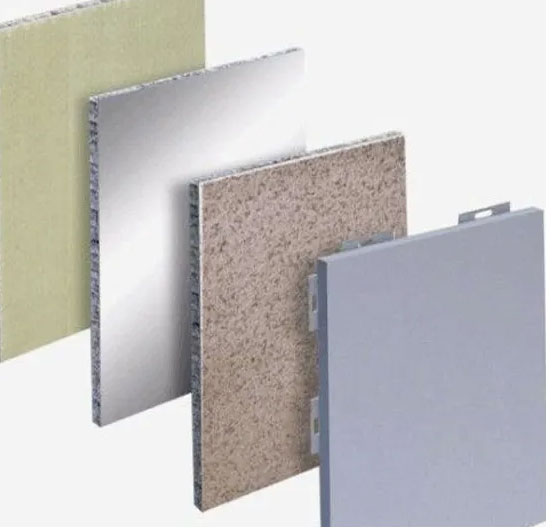

Honeycomb aluminum panel is a new type of decorative material, which is made of high-quality aluminum panel, aluminum back panel, and aluminum honeycomb core through high-temperature compounding.

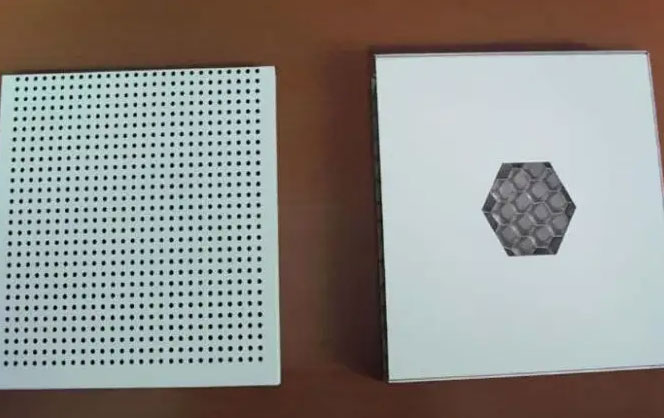

A honeycomb panel is a board made of two thinner panels firmly bonded on both sides of a thicker honeycomb core material, also known as a honeycomb sandwich structure.

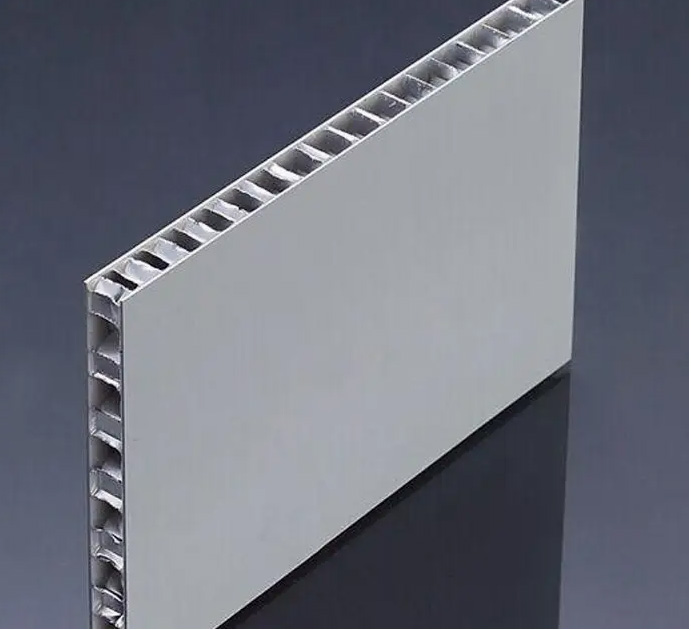

This honeycomb sandwich structure not only improves its overall strength but also improves the overall stability so that the mechanical properties of the panel and the whole are also improved. In addition, as the height of the honeycomb aluminum sheet increases, the moment of inertia of the section increases exponentially, so that the overall structural performance of the honeycomb aluminum sheet is stable, not easy to deform, and has good compression and bending resistance. Therefore, honeycomb aluminum panels are deeply loved by designers.

Because honeycomb aluminum panels are relatively common, with rich product specifications and changeable shapes, they are deeply loved by designers, and because they are large panels and have high flatness, they are widely used. In addition, what other advantages does the honeycomb aluminum plate have?

Honeycomb aluminum panel is a green building material with a high recycling rate

Honeycomb aluminum panels can be regarded as building materials with a high recycling rate. This material will not pollute the environment during use and can be recycled at a high recovery rate after being discarded, and the recycling rate can reach 75%.

Abandoned honeycomb aluminum panels will not put pressure on the environment, and can be described as a veritable green material. In today’s increasingly prominent energy and environmental issues, this feature of honeycomb aluminum panels is particularly valuable.

Honeycomb aluminum plate has good durability and corrosion resistance

Honeycomb aluminum panel has good weather resistance, durability, and corrosion resistance, and has a long service life compared with other materials.

The architectural decoration formed by the honeycomb aluminum plate can even obtain a life cycle synchronized with the main structure of the building. Because of the advantages of honeycomb aluminum panels, there is no need for frequent replacement or maintenance, which makes honeycomb aluminum panels widely used in construction.

Honeycomb aluminum panel is a lightweight, high-strength aluminum material

Compared with traditional building materials, lightweight and high strength are the outstanding advantages of honeycomb aluminum panels. Therefore, the combination of honeycomb aluminum panels and modern light building structure can greatly reduce the overall weight of the building, which is conducive to the refined development of building structural components and also brings more flexible and free development space for the building.

The use of honeycomb aluminum panels can greatly shorten the construction period

The high-precision mechanical prefabrication enables the honeycomb aluminum panel to complete most of the assembly work in the factory, so the remaining works can be completed by simply connecting and assembling on the construction site, which greatly shortens the construction period. At the same time, the participation of large-scale machining will reduce labor costs and reduce labor costs.

Honeycomb aluminum plate has a strong modeling ability

Honeycomb aluminum plate has strong toughness and good ductility. Compared with other materials, honeycomb aluminum plate is easier to bend and form, and has better plastic deformation ability.

In addition, the honeycomb aluminum panel will not weaken the rigid strength it should have due to the bending and twisting of the surface, so there is no need to worry about unexpected dangerous situations such as stones and glass that may be damaged by external forces.

Its super curve shaping ability can adapt to various complex architectural forms such as bending, breaking, and twisting and create a variety of architectural shapes.