Aluminum Coil or Copper Coil?

In AC it has been debating for over and over again, what on earth is better, today let me tell you a final answer to this hard question. This article will discuss this question from a buyer’s viewpoint. For industry arguments about copper, each contractor has a primarily sales-orientated end goal. Buyers focus on heating and cooling installation and repair dealers to hedge the details. Due to the competition of price in the HVAC industry, it becomes a mindset.

Points of Aluminum Coil or Copper Coil- Homeowners Concerned Most

Points of the homeowners and business owners of AC concerned most is that Which works better? air conditioning with copper condensing coils, or air conditioning with aluminum condensing coils?

It seemed to be somehow tinted by manufacturers that economics even though the information presented from governmental and educational resources. A better heating and cooling solution is wanted to all of us, while it’s just a question of how to get marketing share.

For most American cooling and heating, all major brands of heating and cooling equipment were carried into various major brands. We deal with units crated with copper condensing coils and aluminum condensing coils. Our purpose may indeed be economics, or without profit, we would fade away.

Nevertheless, Chal aluminum sticks to satisfy all customers’ needs or demands. The following info will help you to understand how the difference is.

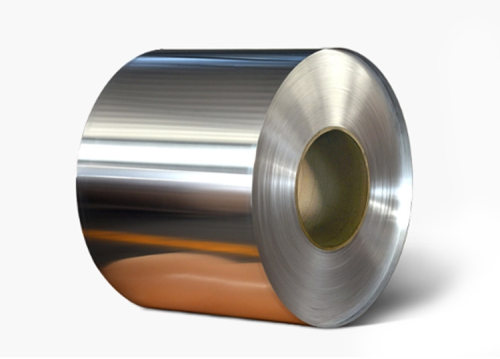

Aluminum Condenser Coils – The Origin

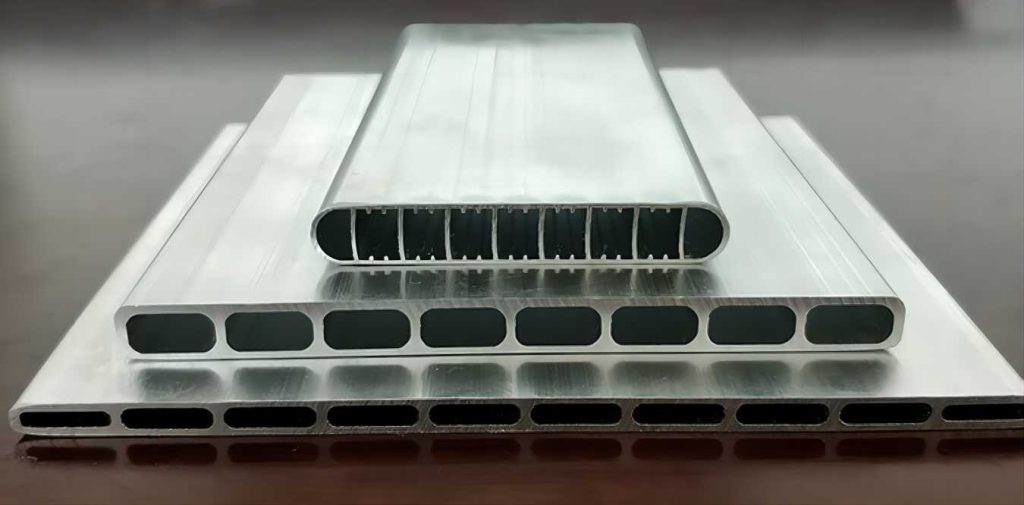

It was in the 1970s when General Electric was still in the HVAC business, the Aluminum condenser coils began to be adopted. And all the AC producers use aluminum fins bonded to the copper tubes as condensing units. While GE wanted to cut production expenses, which followed with the coils with aluminum tubes and aluminum fins.

It was a huge industrial change for the most part. Before 1980, only about 20% of residential structures were air-conditioned. Air-conditioning components and air-conditioning installation costs make air-conditioning a luxury. Few homeowners can afford central heating and cooling.

Then the market changed. Construction is booming. Inflation invades. With rising housing prices, the home air-conditioning market is booming, becoming a lucrative company.

The use of aluminum coils provides GE with a competitive advantage. Soon after, other AC manufacturers began to make their own versions of compatible aluminum coil solutions. GE is no longer involved in the HVAC business, but aluminum tubes with aluminum fin condensing coils are still a stable market product.

Is copper really more durable than Aluminum? The answer is no.

The debate over this matter fell on both sides of the street. Some reasoning can be scientifically proven. Some reasoning is just the preference of individual dealers. From a scientific point of view, the most statements are correct-provided that all pipe measurements between components are the same, which is that copper has more good features than aluminum.

However, due to manufacturing costs and efforts to keep up with the unit price reduction associated with devices using aluminum tube coils, manufacturers of copper-based coil systems have adopted methods to reduce the thickness of the copper tube wall. Therefore, strength, reliability, and durability are related to the actual components used in the air conditioning construction phase.

The US Department of Energy does not provide statistics on leaking air conditioning coils (aluminum or copper). The rule is simple: if your equipment has insufficient refrigerant, ask a trained air-conditioning technician to repair the leak, test the repair, and then charge the equipment according to the manufacturer’s recommendations.

Galvanic action describes the leakage that occurs when oxygen reaches the contact point between the aluminum in the condensing coil and the copper in the condensing device. The problem is generally considered to be irreparable. Qualification: More and more air conditioning repair centers are now equipped with welding equipment capable of welding aluminum. Over the years, the aluminum coil repair process has been improved and may continue to improve in the future.

In the early days of aluminum condensing coils, Arizona AC contractors tended to use copper tubes with finned coils. However, the transition may be happening. Regardless of other arguments, unit cost is still the main factor in any air conditioner purchase decision. Eg:

| Aluminum Coil | Copper Coil | |

| Price | More Favorable | Expensive |

| Flexibility | Well | Need more material added |

| Galvanic Corrosion | Well resistant | Common problem |

| Thinness | Thin while durable | Thin with repair issues |

The manufacturing cost of aluminum coils is lower than that of copper coils

Due to flexibility, copper coils require more material than aluminum coils (even up to three times the material); this leads to higher manufacturing costs.

Galvanic corrosion is a common problem for all copper pipes.

In order to maintain price competitiveness, use unqualified coils when new equipment is shipped.

The thinner the copper, the more difficult it is to repair the coil.

Copper is harder to damage than aluminum, provides better heat transfer and is easier to clean. Modern engineering eliminates most galvanic corrosion. The price of these devices is still much higher than that of AC equipment constructed with aluminum condensing coils. The homeowner questioned the value of the exchange.

Summary

Without the collected statistical data, concerns about leaks and early system failures are difficult to substantiate. All-aluminum coils are more fragile than copper tube coils, but manufacturers solve this problem by protecting the units in heavy-duty cabinets. Of course, this makes the system more difficult to clean and maintain. So as above points, the Aluminium coil is the better financial choice for AC applications.