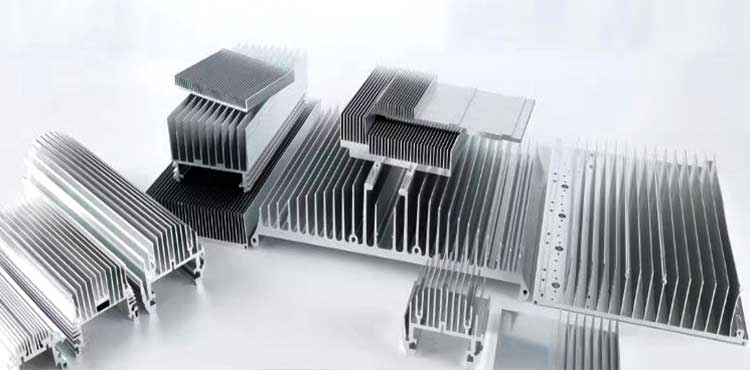

How do make the car run faster and more fuel-efficient? In addition to giving more advanced powertrains, car manufacturers have another trick: weight reduction. Among them, the application of lighter aluminum materials in automobiles is particularly important. The most common example should be rims – for many models, aluminum alloy rims are an important means for car manufacturers to distinguish between high and low parts.

The doors of the Audi A6L and the engine cover of Volvo models are made of aluminum alloy. Now countless new mid-size cars use aluminum alloy lower arms, even on models such as the Jaguar XE and the new Ford F-150. All-aluminum body is adopted.

So, with aluminum body and components, how safe is it? Today we will talk about aluminum car parts in 10 minutes

Aluminum car parts, will it be unsafe?

As the most concerned point of the aluminum car body, Che Jujun interviewed Liu Qing, vice president of Asia for the automotive business of Novelis, the world’s leading manufacturer of aluminum rolled products. He said that aluminum alloy materials can improve the safety of automobiles. There are several benefits:

▎The advantages of aluminum for body structure design

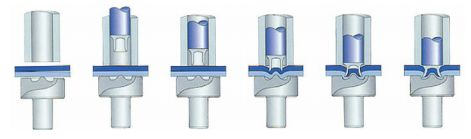

Compared with steel, aluminum is easier to predict the collision result in the design process, so that the possible situations that may occur in the event of a collision can be fully considered, the structure and reserved space can be guaranteed, etc., and the safety of the vehicle can be improved.

▎The performance of aluminum in the life cycle of the car is more stable

Aluminum’s corrosion resistance reduces damage to the vehicle’s structure during the vehicle’s life cycle, thereby continuing its ability to absorb crash energy.

▎Lighter aluminum body for improved braking performance

As we all know, the lighter the vehicle, the smaller the inertial force and the shorter the braking distance. The benefits are obvious – proactively avoiding accidents is always better than passively mitigating them.

The all-aluminum body of Ford’s 2015 F-150 is a good example of the lightweight benefits. Compared with the 2014 body, the new body “slims” up to 318 kg, which can help the F-150 to haul and tow more weight while shortening the braking distance. The model received the highest NHTSA five-star safety rating and is the only full-size light truck to receive the best safety rating in all crash test modes and cab configurations.

At present, the yield strength of some aluminum alloys (such as Novelis 7000 series) can reach more than 500-600MPa. Although aluminum alloys can replace many parts of general-strength steel, there is still a gap compared with high-strength steel.

Therefore, even in models with an all-aluminum body, high-strength steel is used in important stress areas. For example, in addition to the all-aluminum body of the 2015 F-150, the proportion of high-strength steel used in the frame has increased from 23% of the previous generation to 77%.

How much does an aluminum car body cost?

At present, aluminum has been widely accepted by major OEMs around the world because it can support large-scale industrial production, which is very important for the automotive industry.

The American Academy of Sciences was surveyed in 2011 and found that there are dozens of technical paths and means to achieve vehicle light-weighting. Considering the cost, the lightweight of the aluminum body, including the structure, is the most economical way and means of lightweight, which is why aluminum is widely used. Many experts say that aluminum will become the second-largest automotive material after steel.

There are also data showing that the material cost of general aluminum plate parts will increase by 2-5 times than that of ordinary steel plates. This cost difference is a bit scary for a normal car, but for luxury cars and electric cars that don’t skimp on the cost, this cost increase is acceptable.

Now, even some experts say that there is no electric vehicle without lightweight, which shows that there will be greater demand for lightweight electric vehicles in the future. Compared with the carbon fiber materials used in the BMW i8 and the new 7 series, the application of aluminum in electric vehicles will be more extensive and the cost will be lower.

According to statistics made by the European Aluminum Association (EAA), for an electric car the size of the Volkswagen Golf, the cost of an all-aluminum body and an all-steel body will be about 1,015 euros (about 7,259 yuan) more.

However, if it is used in electric vehicles since the use of steel increases the curb weight of the car, a larger battery pack is required to drive, and the battery cost will be 1,650 euros (about 11,800 yuan) higher. After offsetting the 1,015 euros for the cost of aluminum, The overall price is still 635 euros (about 4541 yuan).

In addition, as governments of various countries have stricter requirements on fuel consumption and emissions of car companies, the necessity of lightweight for car companies is increasing, and the production and sales of electric vehicles continue to grow, the automotive aluminum market will continue to grow, thereby promoting Costs are further reduced.

Aluminum bodywork has become mainstream

The all-aluminum body frame structure creatively combines steel and aluminum materials to ensure a more dynamic driving capability, while improving stability and greatly enhancing acceleration capability. This layout achieves excellent body stiffness and good crash safety, and significantly reduces body weight. Stiffness is increased by 60%, solder joints are reduced by 40%, and weight is reduced. Whether it is flexibility, safety, or smoothness are all outstanding. This technology was used in the Audi A8 in 1993, and the latest ASF technology is also used in the Audi A8 and A2.

It can be seen that aluminum car bodies are becoming the new mainstream. Not only the body frame but also body parts are gradually using aluminum as new material.