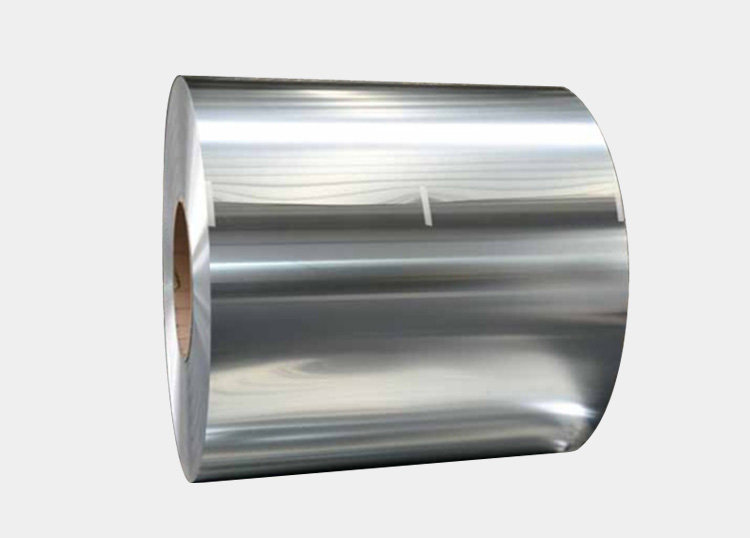

Aluminum foil also named tin foil, is just as thin as a paper, a shinny sheet that is made of aluminum metal. The main production process is by rolling large slabs of aluminum until they are thinner than 0.2mm thick.

It has various of function, and being applied in many applications which include packing, insulation and transportation. It has become a available daily necessity which can be seen in common grocery stores.

People use aluminum foil for food storage at home, to pack foods and to cover baking surfaces, like meats, it help prevent from moisture lose while cooking efficiently.

Wrapping and protecting more delicate foods, such as vegetables when people grilling them, it also works well, that’s also the reason people take it in daily use.

While for this common tool which is around our life, do you know how does the shinny side of Aluminum Foil work in convection? Will it affect it in a bad way? In this article, let’s find out the reason.

How do the different sides come out?

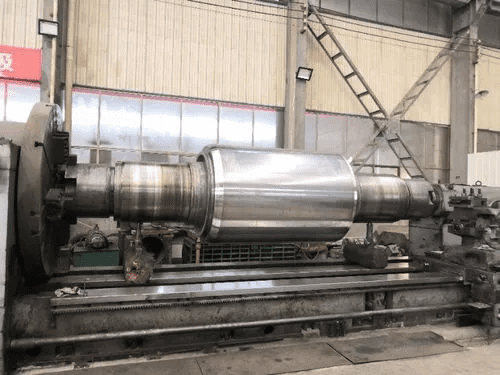

The aluminum foil has a smooth surface and a matte surface. A shiny and smooth side is created when aluminum is rolled in the last pass. It is difficult to produce a roll thin enough to fit the thickness of the foil, so for the final pass, two plates are rolled at the same time, doubling the thickness at the entrance of the roll. When the paper is separated later, the inner surface is matte, while the outer surface is glossy. This difference in finishes leads people to think that preference for one side will have an impact when cooking. Although many people (erroneously) believe that different characteristics can prevent heat from entering when the light side is wrapped outwards, and retain heat when the light side is inward, the actual difference would be unnoticeable without equipment. The increased reflectivity reduces the absorption and emission of radiation.

Does the shinny side affect the convection?

No matter why one side of the aluminum foil is shinny and the other side is dull, it stands to reason that a shinny surface is more reflective than a dim surface. The explanation given seems to indicate that since the light and dark sides are just by-products of the manufacturing process and are not deliberately placed there, there is no difference between them. This interpretation does not support the claim. So what is the truth?

The truth is it won’t affect a convection. The shiny surface should not have an effect on convection, but it will have an effect on radiation. A shiny surface reflects waves better than a dull surface. The reason that one side of the aluminum foil is brighter than the other is that it is smoother and has fewer defects: hills and valleys. Therefore, the shiny surface of the foil should reflect more radiation than the matte surface, which will better capture incident waves instead of reflecting them back. But it should not affect convection, the main source of heat transfer.

Aluminum’s Advantages

Aluminum foil has unique dead-angle characteristics, making it ideal for packaging and repacking many different products and product shapes, while minimizing the need for sealants. Because it is very malleable, it can be easily deformed without losing its barrier integrity, making it an ideal material for use in combination with other flexible substrates, making very thin laminates for various markets, saving resources again .

Aluminum foil has many characteristics, so it is widely used as packaging aluminum foil, such as food, beverage, cigarette, medicine, household aluminum foil, etc. In addition, it can also be used as electronic capacitor materials, building materials, thermal insulation materials, printing materials, signs or label materials, and so on. In all these applications, it can be used as a packaging material to greatly reflect the characteristics of aluminum foil. Lanren aluminum foil can produce all kinds of high-quality aluminum foil, which has won the praise of customers.