In the realm of construction, cost-effectiveness is a paramount consideration for builders, architects, and project managers alike. Balancing quality, durability, and affordability is essential to ensure the success of any construction project. So, maybe you will ask: what is the best grade of aluminum for construction? One material that has gained significant traction for its ability to meet these criteria is 6063 aluminum extrusions. In this article, we will delve into why 6063 aluminum extrusions are increasingly becoming the preferred choice for cost-effective construction solutions.

Properties of 6063 Aluminum Extrusions

6063 aluminum belongs to the 6000 series aluminum alloys, known for their excellent balance of strength, weight, and corrosion resistance. Here’s a closer look at the key properties that make 6063 extrusions ideal for construction:

- Strength-to-Weight Ratio: 6063 offers good strength without excessive weight. This allows for the creation of lightweight structures that can withstand significant loads.

- Corrosion Resistance: The natural oxide layer on aluminum provides excellent resistance to rust and corrosion, making it suitable for various environmental conditions.

- Workability: 6063 aluminum is easily machined, welded, drilled, and formed, allowing for on-site adjustments and customization.

- Durability: With proper maintenance, 6063 aluminum extrusions can last for decades, offering a long-term return on investment.

Overall, the combination of corrosion resistance, strength-to-weight ratio, workability, durability makes 6063 aluminum extrusions an ideal choice for a wide range of construction applications, from structural framing to architectural detailing.

Cost Benefits of 6063 Aluminum Extrusions

The cost benefits of 6063 aluminum extrusions stem from several factors that contribute to overall project savings:

- Efficient Fabrication and Processing: The extrusion process used to manufacture 6063 aluminum extrusions is highly efficient and economical. It allows for the creation of complex shapes and profiles with minimal waste, resulting in higher material utilization and lower production costs compared to traditional manufacturing methods.

- Reduced Labor Costs: The lightweight nature of aluminum makes handling, transportation, and installation easier and less labor-intensive compared to heavier materials like steel. This reduces the labor costs associated with construction projects, as fewer workers are required for handling and installation tasks.

- Long-Term Cost Savings: While the initial upfront costs of aluminum extrusions may be comparable to other materials, the long-term cost savings can be significant. Aluminum is inherently corrosion-resistant, which reduces the need for maintenance and repair over time. Additionally, its durability and longevity ensure that structures built with aluminum extrusions have a longer service life, reducing the need for costly replacements or renovations.

- Recyclability: Aluminum is highly recyclable, meaning that scrap material generated during the fabrication and installation processes can be collected and recycled into new aluminum products. Recycling aluminum requires only a fraction of the energy needed to produce primary aluminum from bauxite ore, resulting in significant energy savings and environmental benefits.

Overall, the cost benefits of 6063 aluminum extrusions make them an attractive choice for construction projects seeking to optimize budgets without compromising on quality or performance.

Design Flexibility and Efficiency of 6063 Aluminum Extrusions

The design flexibility and efficiency of 6063 aluminum extrusions make them highly advantageous for construction projects. Here’s how:

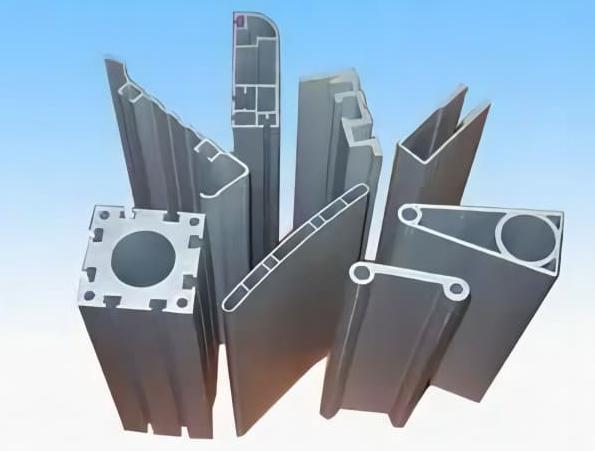

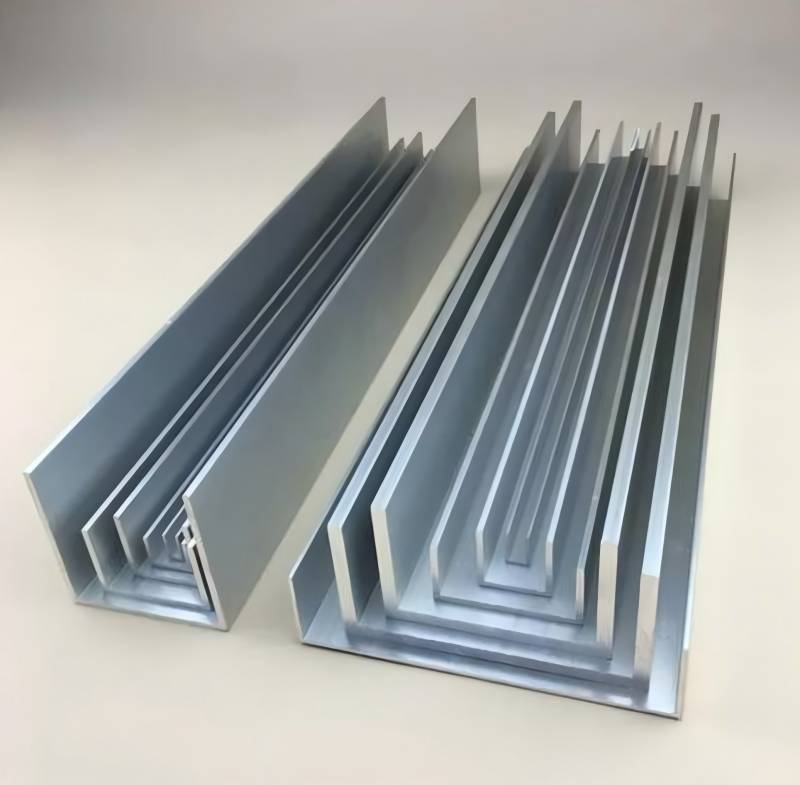

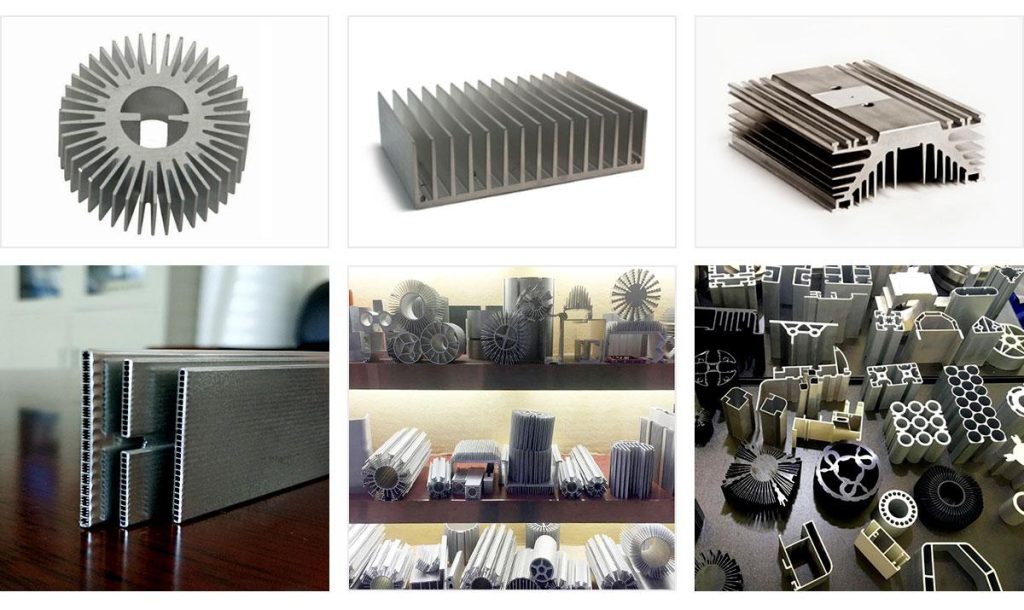

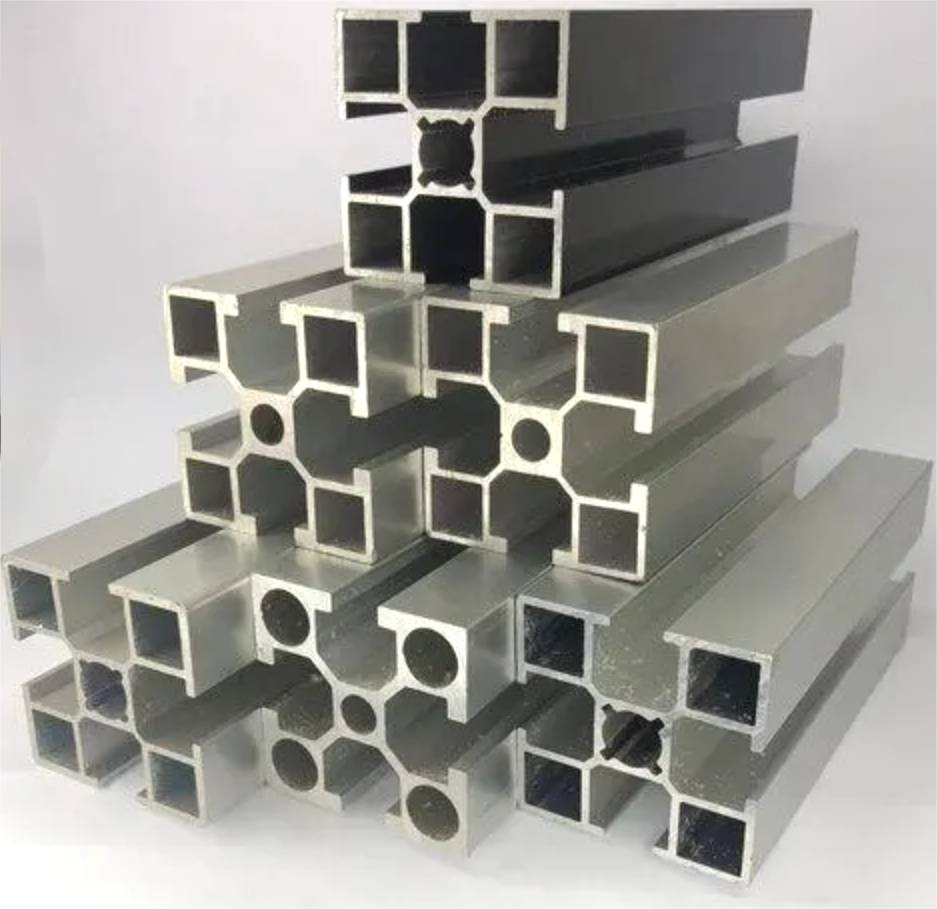

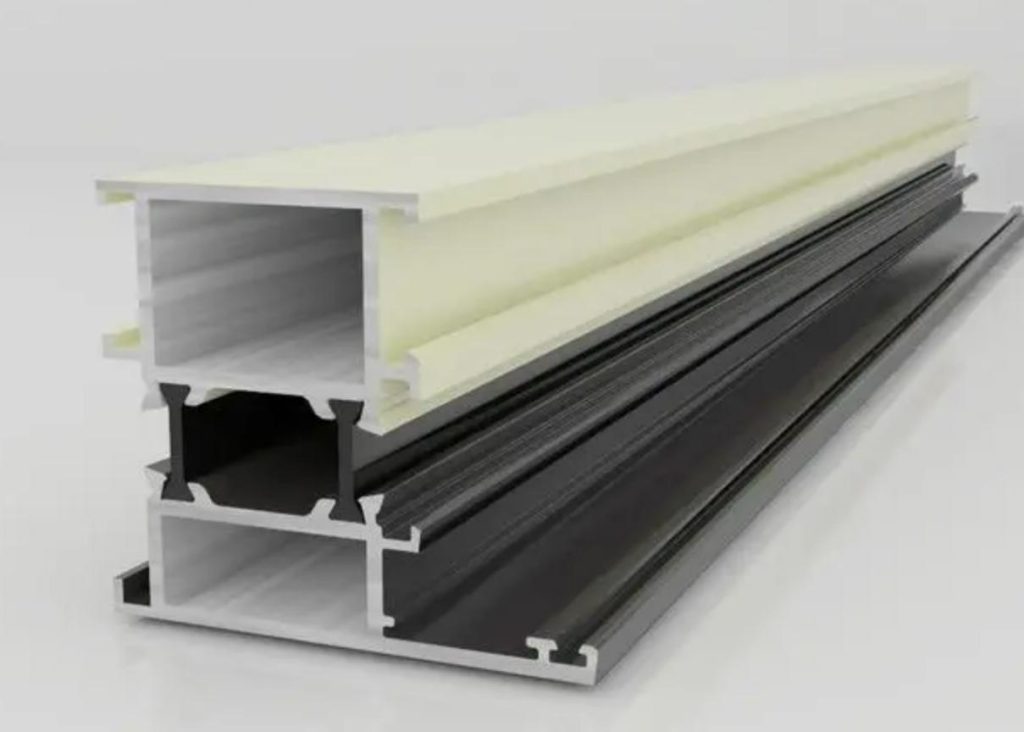

- Customizable Shapes and Profiles: 6063 aluminum extrusions can be easily customized to create a wide variety of shapes, profiles, and geometries to suit specific design requirements. The extrusion process allows for precise control over cross-sectional dimensions, enabling architects and designers to achieve intricate designs and complex configurations that may be difficult or costly to achieve with other materials.

- Intricate Architectural Details: The versatility of 6063 aluminum extrusions allows for the creation of intricate architectural details and features, such as decorative trims, fins, and panels. These elements can enhance the aesthetic appeal of buildings and structures, adding visual interest and character to architectural designs.

- Seamless Integration with Other Materials: 6063 aluminum extrusions can be seamlessly integrated with other materials commonly used in construction, such as glass, wood, and concrete. This enables architects and designers to combine different materials to achieve desired aesthetics, functionality, and performance while leveraging the unique properties of each material.

- Modularity and Prefabrication: Aluminum extrusions are highly modular and can be prefabricated off-site to streamline construction processes. Prefabrication allows for faster assembly on-site, reducing construction time and labor costs while minimizing disruptions to surrounding areas. Modular construction also offers greater flexibility and scalability, allowing for easy expansion or modification of structures as needed.

- Energy-Efficient Design Solutions: Aluminum extrusions can be used to create energy-efficient design solutions, such as thermally broken window and door frames, shading devices, and solar panel mounting systems. These energy-efficient design features help improve the thermal performance of buildings, reduce energy consumption, and lower operating costs over the lifetime of the structure.

Overall, the design flexibility and efficiency of 6063 aluminum extrusions enable architects, designers, and builders to realize their creative visions while optimizing construction processes, reducing costs, and enhancing the performance and sustainability of buildings and structures.

Applications of 6063 Aluminum Extrusions

The versatility of 6063 aluminum extrusions makes them a popular choice across various construction applications:

- Building Exteriors: Cladding systems, window frames, curtain walls, soffits, and fascias.

- Interior Applications: Framing systems for partitions, doors, shelving, and even furniture.

- Structural Applications: Lightweight beams, trusses, and support structures.

- Miscellaneous Uses: Cladding for balconies, railings, and decorative elements.

Conclusion

6063 aluminum extrusions offer a compelling combination of strength, weight, corrosion resistance, and cost-effectiveness. Their favorable properties, cost benefits, design flexibility, and wide-ranging applications make them an ideal choice for builders looking to optimize project budgets without compromising on quality or performance. If you are looking for a 6063 aluminum extrusion supplier, please feel free to contact CHAL. They will provide you cost-effective products and services.